How is Tungsten Wire Used in Glass Cutting?

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 July 2025 18:47

- Written by Zhenghua

- Hits: 12

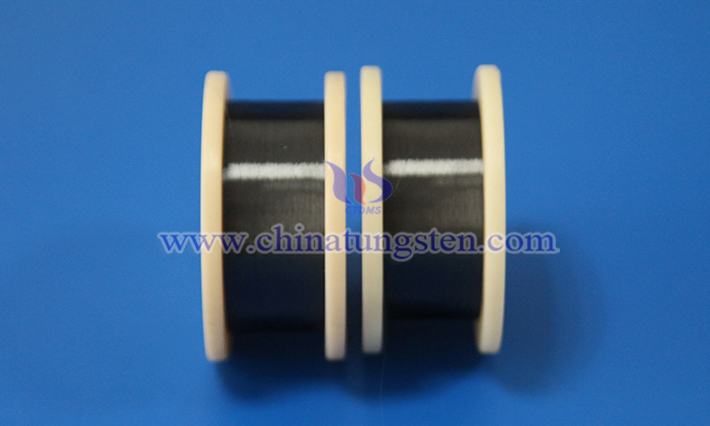

The application of tungsten wire in glass cutting mainly relies on its high strength, conductivity and high temperature heating ability. It can achieve precise cutting through thermal stress cracking, local softening or combined with abrasives and mechanical movement. It is particularly suitable for the processing of thin glass and optical components.

1. Hot Wire Cutting

The main function of tungsten wire in glass cutting is to generate high temperature through resistance heating, induce local softening or thermal stress cracking of glass, and thus achieve cutting. After tungsten wire is energized, it can quickly heat up to hundreds to one thousand degrees Celsius, which is far below its melting point but enough to affect glass (melting point is about 1400-1600°C). By precisely controlling the temperature, tungsten wire can locally heat the surface of the glass, produce thermal stress differences, cause controllable cracks to expand along a predetermined path, or directly soften the glass for separation.

2. Laser-Assisted Cutting

In some precision cutting, in laser glass cutting, tungsten wire can be used as a preheating tool to locally heat the glass surface and reduce the risk of microcracks caused by rapid temperature differences during laser cutting. This method is particularly important in the processing of high-precision optical components. The preheating effect of tungsten wire can optimize the heat distribution of glass and improve the quality of cutting edges.

3. Wire Cutting

Tungsten wire can be used in wire cutting equipment as a cutting wire through mechanical pulling, combined with abrasives (such as diamond powder) or thermal effects to cut glass or glass composites. The thinning of tungsten wire diamond wire makes it widely used in the cutting of photovoltaic crystalline silicon.

4. Application Characteristics of Tungsten Wire in Glass Cutting

High temperature resistance and stability: The high melting point and corrosion resistance of tungsten wire enable it to work for a long time in a high temperature environment, suitable for repeated cutting tasks.

High precision: Tungsten wire can achieve micron-level precision, especially suitable for cutting thin glass or regular paths, with smooth edges and reduced subsequent grinding requirements.

Flexibility: Tungsten wire can adjust the heating temperature and cutting speed as needed to adapt to different types of glass materials.

Limitations: Tungsten wire material cost is relatively high and is not suitable for general glass cutting.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com