Prevent WO3 Waste Flue Gas Denitration Catalyst Regeneration Pollution

- Details

- Category: Tungsten Information

- Published on Thursday, 14 April 2016 17:15

- Written by chunyan

- Hits: 250

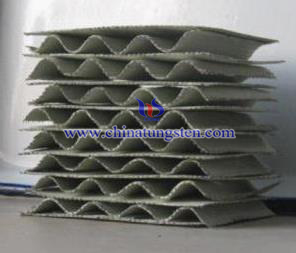

At present, the NOx in China is mainly coming from coal-fired power plants, tungsten trioxide SCR denitration catalyst is widely used as the best denitration technology due to the nice properties such as high denitration rate, selectivity, mature and reliable. However large numbers of toxic and hazardous waste gas tungsten trioxide denitration catalysts are produced with the ongoing SCR project. Therefore, strengthening the management of waste gas denitration catalyst for preventing human health and environment being damaged is necessary.

At present, the NOx in China is mainly coming from coal-fired power plants, tungsten trioxide SCR denitration catalyst is widely used as the best denitration technology due to the nice properties such as high denitration rate, selectivity, mature and reliable. However large numbers of toxic and hazardous waste gas tungsten trioxide denitration catalysts are produced with the ongoing SCR project. Therefore, strengthening the management of waste gas denitration catalyst for preventing human health and environment being damaged is necessary.

The activity of waste flue gas denitration catalyst can be restored or upgraded after regeneration, thus to achieve the goal of recycling and saving resource. There are two denitration catalyst regeneration treatments, respectively: on-site regeneration, and factory regeneration. Because the ability of waste gas tungsten oxide denitration catalyst regeneration is serious poor, so far the main way in China is on-site regeneration. However, since the on-site regeneration is very dangerous, which is easily causing the site environment and water pollution; others, the denitration ability can’t meet the requirements after on-site regenerated. Therefore, the factory regeneration is suggested for avoiding secondary pollution.

The real factory regeneration of waste tungsten trioxide denitration catalyst is a complex physical and chemical processes, and the chemical composition of regenerated catalyst can be well controlled; more importantly, the activity of catalyst recovered can even reach 100%, by the way, it can be tailored. The key technologies of waste tungsten trioxide denitration catalyst regeneration process include: high-pressure water washing, ultrasonic washing, pickling, active implants and high-temperature calcination; its major regeneration aspects include: pretreatment, cleaning, pickling, drying or calcination, wastewater treatment, waste gas treatment and other processes.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com