Tungsten Copper Properties Comparison of Different Process (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 16:37

- Written by xiaobin

- Hits: 262

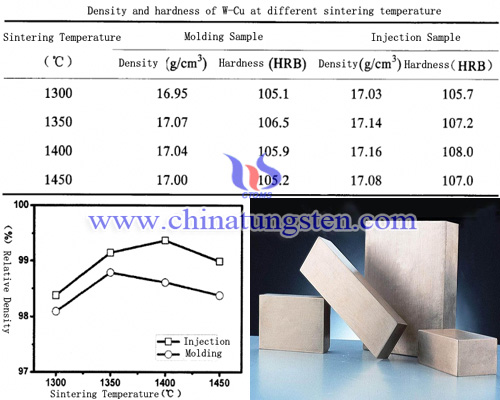

Take W-Cu tungsten copper product as a example to compare molding process with injection molding of tungsten copper material properties. W-Cu theoretical density is 17.28g / cm3, the trend of relative density and relative density with the sintering peak temperature given as follow:

As we can see from this graph above, With increasing sintering temperature, density of the obtained two processes copper tungsten composites are showing trend of increased first and then decreased. The difference is the temperature of the maximum density, the highest density of molded samples at 1350 ℃, reaches 17.16g / cm3, while the sample injected at 1400 ℃ highest density is 17.17 g / cm3. After the further increase in temperature, both the density began to decrease. This is due to the sample over-burnt, Cu phase inside of tungsten copper exudates to surface and the pores and defects left in side. Under the optimum sintering temperature, the density of injected sample reaches 99.31%, molded samples reaches 99.78%. In addition, the hardness of tungsten-copper composite material (HRB) was positively correlated to its density, the greater the density, the hardness of the respective materials is also greater.

Besides, we also compare the micro-structure of tungsten copper with different processes. The specific procedure is that milled, polished tungsten copper composite sample after etching with FeCl3 salt solution for 2 minutes, with water to clean the surface of the etching solution, then wipe the surface with alcohol cotton, and then drying, Finally placed under microscope observation of the metallurgical microstructure. By comparing the SEM photomicrographs and photographs can be found that tungsten copper molded sample of W, Cu two-phase distribution is more uniform, uniform grain size, but segregation occurs at a constant temperature inside, causing a regional copper-rich, there are some porosity. While tungsten copper sample by injection molding, W and Cu distribute uniform and does not exist W-rich phase and Cu-rich phase of the phenomenon and Cu phase forms net structure around tungsten grains.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com