Controlled Synthesis of Tungsten Disulfide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Thursday, 25 August 2022 16:28

- Written by Caodan

- Hits: 1249

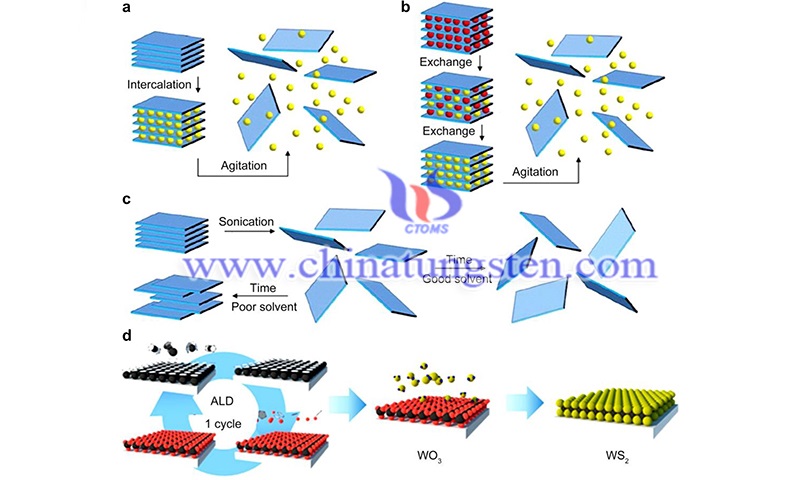

1T-WS2 structure and 2H-WS2 structure of tungsten disulfide nanomaterials controlled synthesis is important. The 1T-WS2 structure is considered an efficient co-catalyst for hydrogen evolution due to the increased density of catalytic active sites and the metal conductivity, while the 2H-WS2 structure can be used as a visible photosensitizer. Therefore, various synthetic methods for the crystalline phase modulation of WS2 have received much attention. Since the conversion from 1T-WS2 to stable 2H-WS2 can be easily achieved by annealing, the study of feasible methods to achieve the opposite conversion has received much attention.

Read more: Controlled Synthesis of Tungsten Disulfide Nanomaterials

Electrical Characteristic and HER Mechanism of Tungsten Disulfide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 August 2022 20:46

- Written by Caodan

- Hits: 1156

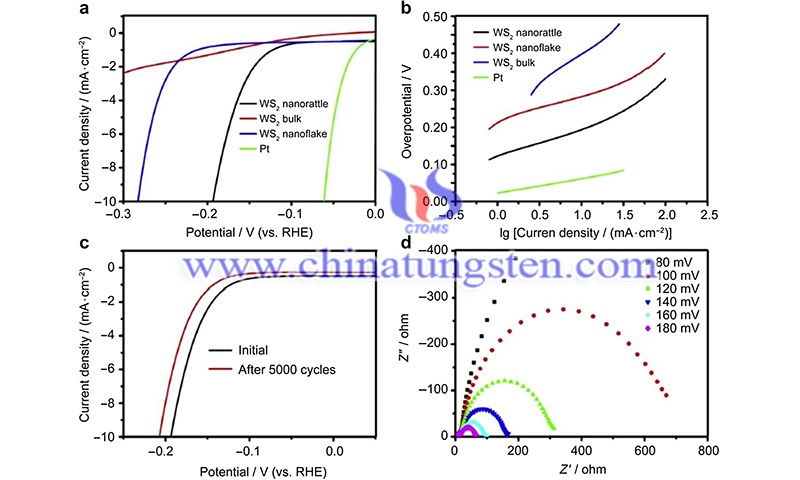

Due to the promising applications of tungsten disulfide nanomaterials in the field of energy conversion and storage, efforts have been made to study and improve its electrical characteristic and HER mechanism of WS2, such as carrier concentration (p), mobility (μ), and resistivity (ρ). According to theoretical predictions, WS2 has the highest electron mobility in semiconductor TMDCs due to the reduced effective mass.

Read more: Electrical Characteristic and HER Mechanism of Tungsten Disulfide Nanomaterials

Tungsten Disulfide Nanomaterials Applied in Energy Conversion and Storage

- Details

- Category: Tungsten Information

- Published on Monday, 22 August 2022 20:38

- Written by Caodan

- Hits: 1189

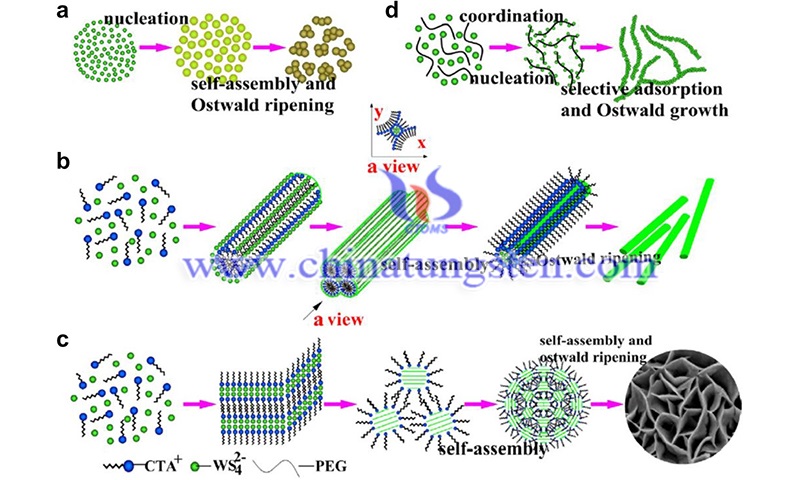

Due to the rapid growth of the global population and rapid socio-economic development, energy and environmental issues have received widespread attention. As a transition metal disulfide, tungsten disulfide nanomaterials have made important research advances in the field of energy conversion and storage. Given the versatility and rich microstructure of these materials, the plasticity and controlled synthesis of tungsten disulfide (WS2) nanomaterials are of interest to researchers.

Read more: Tungsten Disulfide Nanomaterials Applied in Energy Conversion and Storage

Light Absorption and Photocatalytic Characteristics of Tungsten Disulfide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 August 2022 20:35

- Written by Caodan

- Hits: 1183

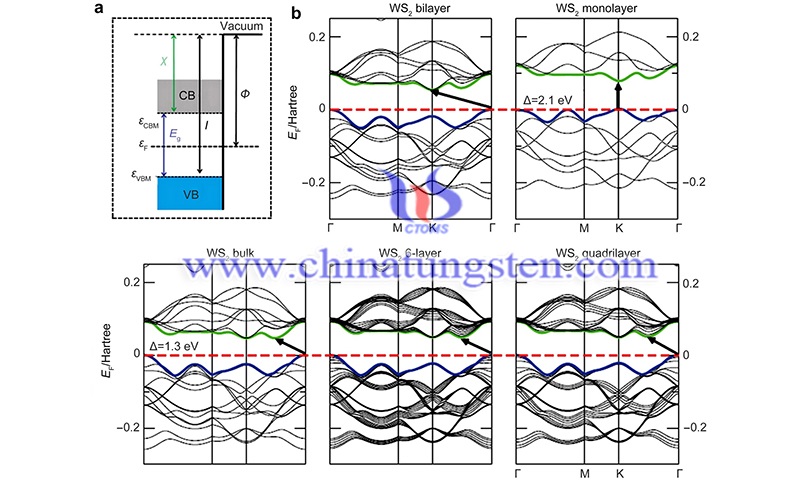

Compared with semiconducting materials, tungsten disulfide nanomaterials exhibit higher light absorption, and photocatalytic properties are another important property. For semiconductor materials, light absorption properties are very important, especially for photocatalysis. When WS2 absorbs photons, transitions between in-band, out-of-band, and impurity defects occur, which can form specific absorption spectra. The characteristic absorption peak of bulk WS2 is near the wavelength of 910 nm and is located in the near-infrared (NIR) region. By forming nanostructures, a blue shift of the WS2 characteristic absorption peak can be observed.

Read more: Light Absorption and Photocatalytic Characteristics of Tungsten Disulfide Nanomaterials

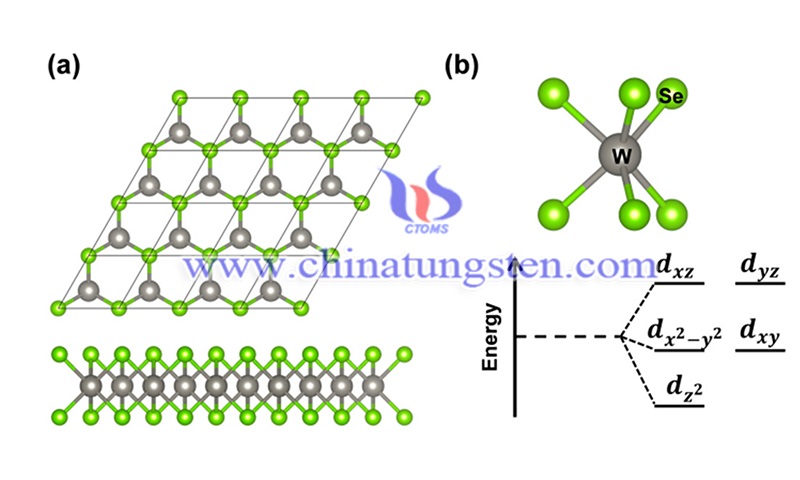

Crystal Structures of Tungsten Disulfide and Tungsten Diselenide

- Details

- Category: Tungsten Information

- Published on Monday, 22 August 2022 20:33

- Written by Caodan

- Hits: 1221

An article published in the Journal of Solid State Chemistry by Schutte et al. illustrates that crystal structures of tungsten disulfide (WS2) and tungsten diselenide (WSe2) host the same type of layered structure as molybdenum disulfide (MoS2). In addition to the common hexagonal 2H form of WS2, a rhombohedral form, 3R-WS2, has also been reported, which is isotypic to the rhombohedral form of MoS2.

Read more: Crystal Structures of Tungsten Disulfide and Tungsten Diselenide

sales@chinatungsten.com

sales@chinatungsten.com