What Is Calcium Tungstate?

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2025 11:37

- Written by Xiaoting

- Hits: 23

Compared to alkali metal tungstates (e.g., sodium tungstate and potassium tungstate), calcium tungstate (CaWO₄) exhibits markedly different crystal structures and properties due to the incorporation of Ca²⁺, evolving from its industrial designation as "synthetic scheelite" to its core application as a scintillator material.

What Is Magnesium Tungstate?

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2025 11:35

- Written by Xiaoting

- Hits: 32

Within the family of inorganic functional materials, magnesium tungstate (MgWO₄) stands out as a representative alkaline earth metal tungstate, leveraging its unique crystal structure and perse properties to deliver significant value in optoelectronic displays, catalytic degradation, and functional ceramics. This compound, formed by magnesium ions (Mg²⁺) and tungstate ions [(WO₄)²⁻], inherits the stability of alkaline earth metals while gaining rich optical and electrical responses from the tungsten-oxygen framework, serving as a bridge between traditional chemistry and emerging optoelectronic technologies.

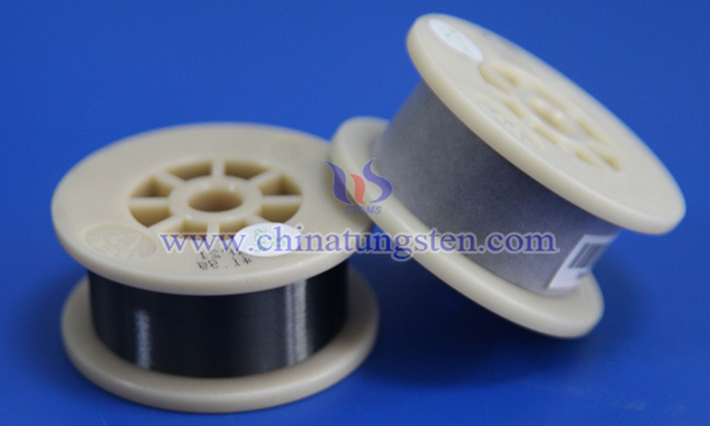

Tungsten Wire for Defrosting Glass

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 July 2025 19:03

- Written by Zhenghua

- Hits: 29

Defrosting glass usually uses tungsten wire as a heating element because tungsten has a high melting point, high temperature resistance and good conductivity, which is suitable for generating uniform heat on the glass surface or in the interlayer to remove frost or ice.

What Is Ferrous Tungstate?

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2025 11:32

- Written by Xiaoting

- Hits: 21

Within the broad field of transition metal compounds, ferrous tungstate (FeWO₄) stands out as a representative example of an iron-group element combined with tungstate, gaining prominence in chemical and materials science research due to its unique physicochemical properties and versatile application potential. This tungstate, formed by Fe²⁺ and (WO₄)²⁻, not only inherits the magnetic commonality of iron-group elements but also exhibits rich functional characteristics due to the introduction of the tungsten-oxygen framework, opening new pathways in catalysis, energy storage, and inorganic material preparation.

Tungsten Wire for Anti-fog Glass

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 July 2025 19:01

- Written by Zhenghua

- Hits: 27

Anti-fog glass usually prevents fog condensation by embedding or coating a conductive material (such as tungsten wire or conductive film) on the glass surface and heating it with electricity. Tungsten wire is often used as a heating element in anti-fog glass systems that require heating, such as car rearview mirrors, bathroom mirrors or refrigerator glass doors, due to its high melting point, high resistivity, high temperature resistance and corrosion resistance.

sales@chinatungsten.com

sales@chinatungsten.com