Evaluation of the Service Life of Tungsten Crucibles

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:23

- Written by Shuxia

- Hits: 125

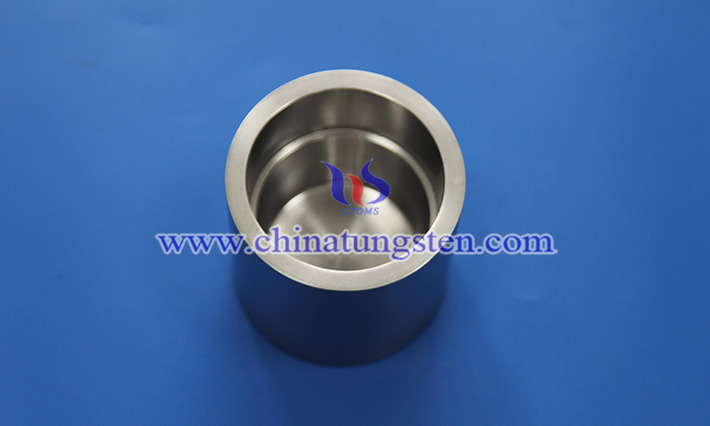

Although tungsten itself has excellent thermal stability and corrosion resistance, the actual service life of tungsten crucibles is affected by a number of factors. Therefore, a lifetime assessment of the system not only helps to improve the efficiency of equipment operation, but also reduces material waste and maintenance costs.

The main factors affecting the life of tungsten crucibles include temperature conditions, working atmosphere, frequency of use, type of smelted material, processing quality and number of thermal cycles. Temperature plays a decisive role. Although tungsten can withstand high temperatures above 3000°C, its thermal conductivity and mechanical strength will still decrease at high temperatures. In addition, the presence of trace amounts of oxygen, water vapor or halogen gas in a high-temperature environment will intensify the oxidation or corrosion reaction on the surface of tungsten, forming volatile tungsten oxide, which will lead to wall thickness thinning and even structural perforation.

The atmosphere of use is also an important dimension for life assessment. When used in an inert atmosphere or vacuum, tungsten crucibles have the best stability and almost no significant chemical changes; In an oxygenated or humid environment, its surface is highly susceptible to oxidation, and the oxide will sublimate rapidly at high temperatures, seriously affecting the structural integrity of the crucible. Therefore, users should keep the environment clean before and after each heat treatment to avoid the accumulation of impurities in the atmosphere, so as to prolong the service life of the W crucible.

In addition, the properties of the melted material can have a significant impact on the life of the tungsten crucible. For example, highly reactive metals such as titanium and zirconium react with tungsten at high temperatures to form brittle compounds that crack or peel off the surface of the crucible. In this case, a protective coating, such as molybdenum, nitride or boron nitride, can be applied to the inner wall of the crucible to isolate the reaction and improve corrosion resistance.

From the perspective of mechanical factors, the processing quality directly determines whether the tungsten crucible can work stably in a high temperature and high pressure environment. If microcracks, voids, or stress concentrations occur during the molding process, these defects will propagate rapidly during thermal cycling, shortening their service life. Therefore, improving density and surface quality is an important technical means to prolong life.

The number of thermal cycles is also a factor that cannot be ignored in life assessment. During each heating and cooling process, the W crucible undergoes thermal expansion and contraction, and if the temperature changes drastically, it is very prone to thermal fatigue cracks. Therefore, it is recommended to avoid excessive temperature rise and fall operation during use, and adopt a uniform heat source control system to reduce the damage caused by thermal stress to the structure.

In order to scientifically evaluate the service life of tungsten crucibles, it is recommended to combine theoretical analysis with practical data accumulation. By monitoring the dimensional changes, mass loss, surface structure changes and crack distribution after each use, and establishing a life prediction model, the remaining service life cycle can be judged more accurately. In addition, combined with finite element thermal stress simulation and analysis technology, it can also assist in optimizing the crucible structure and use parameters, so as to improve its comprehensive reliability.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com