New Tunable Windows Turn Opaque with Switch--Tungsten Trioxide

- Details

- Category: Tungsten's News

- Published on Thursday, 17 March 2016 19:01

- Written by chunyan

- Hits: 663

Imagine a window with no need for cumbersome blinds, but just with a flick of a switch, the glass simply turns opaque. Tungsten trioxide is the material that can be used for preparing tunable windows, the thin coating made by it vacuum deposited on glass. When electricity is applied, it triggers an electro-chemical reaction that turns the material opaque.

The window is made from a stiff sheet of thin plastic or glass, which is inserted between two layers of a transparent rubbery material called an elastomer. The researchers then cover both sides with a network of silver nano-wires. The nano-wires, each a few microns long and 90 nanometers across, are scattered randomly, similar to a game of pick-up sticks. The tiny nano-wires don't scatter light and sparsely cover the surface, leaving the window transparent. But when the electric voltage, it changes. The change in transparency happens quickly, in less than a second the material’s color has been changed without your observing.

This uneven surface scatters light just like how waves on a pool's surface prevent you from seeing into the water. But one of the biggest advantages of using tiny nano-wires is a potentially cheaper and simpler manufacturing process. On the other hand, expensive high-vacuum technology to produce is required.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nanosized Ceramic Powder Market—Tungsten Oxide

- Details

- Category: Tungsten's News

- Published on Thursday, 17 March 2016 18:57

- Written by chunyan

- Hits: 597

Global markets advanced nano-ceramic and ceramic powder should show a solid, and the growth rate of nano-ceramic powder segment should be more than doubled advanced ceramic powder segment, at 2021 significantly expand its overall market share.

Both advanced ceramic and nano-ceramic powders belong to functional ceramics, which can be used in cutting tools to artificial bone implants, mechanical seals, ceramic liners, bearings, thread guides ect.. At present, major efforts are underway to apply structural ceramics to automotive reciprocation engines for wear components.

The performance improvements are the driving force behind the continued development and commercialization of high-performance ceramic coatings. These coatings are generally applied to engineering metals, like titanium alloys, tungsten carbides and other ceramics.

Oxide ceramics will continue to stay in the leading position. Tungsten trioxide being an important functional material is widely applied in electrochromic, toxic gas detection and photocatalytic degradation ect.. High purity tungsten trioxide dense ceramics as a target purposes is particularly important to form an industrialization. Thus reducing the production cost of tungsten trioxide film, sets the foundation for better preparation and properties of tungsten trioxide thin films.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Extraordinary Raw Material in iPhone 6S--Tungsten

- Details

- Category: Tungsten's News

- Published on Thursday, 17 March 2016 18:49

- Written by chunyan

- Hits: 766

Since Apple launched the first iPhone in 2007, the iconic smartphone has sold over 700 million units around the world. This best-selling handset sets the standard for smartphone performance and features. However, the iPhone 6S would not be possible without the extraordinary raw materials that line the insides of the case. So what is in the Apple iPhone 6S?

About the iPhone 6S’s screen, it’s much more complex than it may seem. The potassium ions make aluminosilicate glass strength. A layer of indium tin oxide makes it touchscreen capable and small amounts of rare earths enables certain colors on the display.

Lithium cobalt oxide (LiCoO2) with 60% of cobalt is in the iPhone 6S’s battery, also a graphite anode and aluminum casing are being used.

About the electronics, the phone’s processor is mainly made from silicon, metals like cooper, gold, silver and tungsten are used for electrical connections within a iPhone 6S. Besides, the introduction of tantalum makes the electricity flow managed to guarantee.

Tungsten-copper and tungsten-silver carbide both have the properties as same as copper and silver--the good electrical, thermal conductivity. Thus, making them become very effective contact materials in working parts, such as manufacturing knife switch, circuit breakers, spot welding electrodes.

Things someone really cases is the camera, what is the extraordinary raw material used in Apple 6S’s camera? Sapphire glass, which makes it nearly as hard as a diamond, because of the Moh’s hardness reaches to 9.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Surface Coating Makes Steel Stronger

- Details

- Category: Tungsten's News

- Published on Thursday, 17 March 2016 18:53

- Written by chunyan

- Hits: 661

A newly made surface coating for steel can make it stronger and more resistant to rust and corrosion, according to its developers. Scientists from Harvard's John A. Paulson School of Engineering and Applied Sciences (SEAS) were able to create a surface coating for steel that not only repels corrosion but also makes the metal stronger.

A newly made surface coating for steel can make it stronger and more resistant to rust and corrosion, according to its developers. Scientists from Harvard's John A. Paulson School of Engineering and Applied Sciences (SEAS) were able to create a surface coating for steel that not only repels corrosion but also makes the metal stronger.

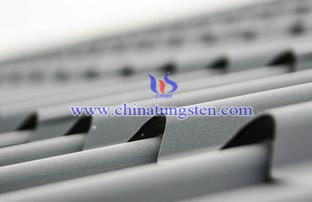

Joanna Aizenberg, a core member of the Wyss Institute for Biologically Inspired Engineering at Harvard University, and her team developed a new surface coating from nanoporous tungsten oxide, which is respected to be more durable than any anti-fouling material that has been developed before. Also the coating had passed the tests: scratching with stainless steel tweezers, diamond-tipped scribers, screwdrivers, beating it hard, anti-wetting properties.

According to the team, they made that possible by making an ultrathin film of thousands of small tungsten oxide islands to directly coat the steel surface. If one part of one island is destroyed, the damage will not spread to other islands due to their lacking of connection. This helps the coating retain its repelling properties while helping the steel improve its durability.

The coating material had potential to be used in different industrial and commercial fields, such as: non-fouling medical devices and tools, 3-D printers, large scale use on buildings and on marine vessels or vehicles. The beneficial properties of the coating may save millions in production and maintenance coats.

Tungsten, a high melting point reaches to 3410°C making it becoming the hardest melting metal. Also it becomes the strategic metal, because its properties that high hardness, strong ductility, no erosion at room temperature in the air. Tungsten oxide, which comes from the tungsten, following its excellent properties, thus it’s possible that tungsten oxide surface coating makes steel stronger and durable.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nanoporous Tungsten Oxide Coating on Steel

- Details

- Category: Tungsten's News

- Published on Thursday, 17 March 2016 17:34

- Written by xinyi

- Hits: 743

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com