Military Tungsten Alloy Swaging Rod & IDAS

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 18:29

- Hits: 1826

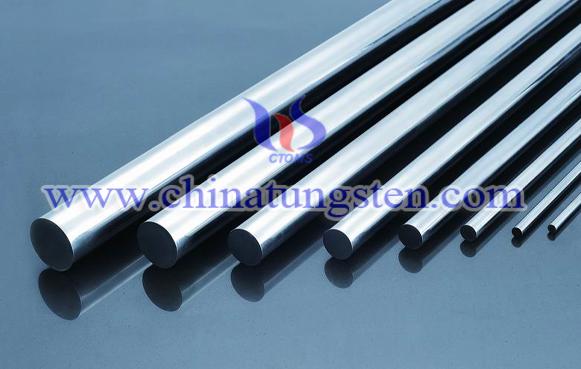

Military tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod is widely used in military ares. Military tungsten alloy swaging rod can be used for IDAS.

IDAS is a short-range missile currently being developed for the new Type 212 submarine class of the German Navy.

IDAS (based on the IRIS-T air-to-air missile) is primarily targeted against air threats, such as ASW helicopters, but also against small or medium-sized surface vessels or coastal land targets. It is currently being developed by Diehl BGT Defence and HDW, which is a part of Thyssen-Krupp Marine Systems (TKMS), to be fired from Type 212's torpedo tubes. IDAS will be fibre-optic guided and officially has a range of approx. 20 km. Four missiles will fit in one torpedo tube, stored in a magazine. First deliveries of IDAS for the German Navy and operational service are planned from 2014 on.

The IDAS system is also the world's first missile which gives submarines the capability to engage air threats whilst submerged, and the first tube-launched missile that does not emerge in a capsule, but is fired directly from the torpedo tubes.

With the high density and hardness of military tungsten alloy swaging rod, IDAS can penetrate armor and destroy helicopter.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Swaging Rod & Tomahawk

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 18:21

- Hits: 1649

Military tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod is widely used in military ares. Military tungsten alloy swaging rod can be used for Tomahawk.

The Tomahawk is a long-range, all-weather, subsonic cruise missile. The missile was named after the Native American axe. Introduced by General Dynamics in the 1970s, it was initially designed as a medium to long-range, low-altitude missile that could be launched from a surface platform. It has been improved several times and, due to corporate divestitures and acquisitions, is now made by Raytheon. Some Tomahawks were also manufactured by McDonnell Douglas (now Boeing Defense, Space & Security).

The Tomahawk missile family consists of a number of subsonic, jet engine-powered missiles designed to attack a variety of surface targets. Although a number of launch platforms have been deployed or envisaged, only sea (both surface ship and submarine) launched variants are currently in service. Tomahawk has a modular design, allowing a wide variety of warhead, guidance, and range capabilities.

With the high density and hardness of military tungsten alloy swaging rod, Tomahawk can penetrate armor and destroy warship.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Swaging Rod & AGM-123

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 18:14

- Hits: 1709

Military tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod is widely used in military ares. Military tungsten alloy swaging rod can be used for AGM-123.

AGM-123 is a short-range laser-guided missile developed by the U.S. Navy.

AGM-123 is a short range missile intended for precision strikes. It is composed of a Mark 83 bomb, fitted with a Paveway kit, and an attached rocket propulsion system to allow it to be dropped at greater distances from the target. Tandem mounted Mk 78 solid propellant rockets which both fire simultaneously on launch provide propulsion.

With the high density and hardness of military tungsten alloy swaging rod, AGM-123 can penetrate armor and destroy warship.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Swaging Rod for Penguin Missile

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 18:06

- Hits: 1620

Military tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod is widely used in military ares. Warhead of Penguin missile is made of military tungsten alloy swaging rod.

The Penguin missile is a Norwegian passive IR seeker-based short-to-medium range anti-ship guided missile, designed for naval use.

Penguin was originally developed in a collaboration between the Norwegian Defence Research Establishment starting in the early 1960s, with financial support from the USA and West Germany. US Navy test facilities and technical assistance were made available to facilitate development.It was the first NATO AShM with an IR seeker (instead of the commonly used active radar technology) and both hardware and software has been updated since entering series production in 1972.

With the high density and hardness of military tungsten alloy swaging rod, Penguin missile can penetrate armor and destroy warship.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Swaging Rod for AS.34 Kormoran

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 17:59

- Hits: 1739

Military tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod is widely used in military ares. Warhead of AS.34 Kormoran is made of military tungsten alloy swaging rod.

The AS.34 Kormoran is a German-produced Anti-ship missile. The Kormoran (cormorant) uses an inertial guidance system for the midcourse phase, switching to active radar homing during the terminal attack phase. It carries a 165 kg (363 lb) delay-fused warhead, designed for 90mm of penetration prior to detonation. The maximum range is 23 km (~14 miles).

With the high density and hardness of military tungsten alloy swaging rod, AS.34 Kormoran can penetrate armor and destroy warship.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Thorium Tungsten Electrode Characteristics and Thorium Tungsten Electrode Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:11

- Hits: 1490

Thorium tungsten electrode characteristics

Thorium oxide containing tungsten thorium ( thorium dioxide or thoria ) , in the United States it is most commonly used tungsten electrodes , determine other tungsten electrodes have become a standard of good or bad . However, since this has a low level of tungsten electrodes radiological hazards , many users have switched to other options. In general , a 2% thoriated tungsten electrode is a relatively good tungsten electrode having the lowest work function , even when the overload voltages also performed well . Thorium tungsten electrode performance in many respects superior to pure tungsten electrodes . Than pure tungsten thorium oxide provides about 20 percent higher than the current carrying capacity , generally longer life , but also help prevent contamination when welding . Using thoriated tungsten electrode , arc easier than that of pure tungsten electrode and the arc or zirconium tungsten electrodes more stable. Thorium tungsten electrode 1% (EWTh - 1) and thorium tungsten electrode 2% (EWTh - 2) can be used for DCEN. They remain in the welding process sharpened tip , which can be used to weld steel pipe , not usually direct current, because it is difficult to maintain a spherical tip welding without cracking , which is a must for direct current .

Thorium tungsten electrode application

Thoriated tungsten electrodes are usually used for the DC negative electrode or carbon, stainless steel, nickel alloys, titanium alloys and other applications of the positive electrode . Their operating performance , even when the overload current of the operation can be very good .

Thoriated tungsten electrode is usually used in the field of carbon and stainless steel . Thorium oxide content of 2% thoriated tungsten electrode is typically less than 1% of the thorium content of the tungsten electrode to better improve performance . Communicate using thorium tungsten electrode welding, faster , and to be used with caution in order before welding on AC DC welding reaction . In AC welding, balled balls will not melt, so the effect is not as liquid ball so well.

Thoriated tungsten electrodes are usually used for DC welding field, while pure tungsten electrodes for AC welding . During the welding process , the staff should carefully read the instructions for use of thorium tungsten electrode .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

About Doped Tungsten Models

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:08

- Hits: 1774

Doped tungsten wire , also commonly known as anti- sag tungsten wire, tungsten, aluminum , tungsten, its main feature is added in the dispersion strengthening elements potassium , forming a " dovetail lap " -shaped interlocking internal grain structure, and thus improved resistance to high temperature creep resistance tungsten .

Doped tungsten complete production line including blue tungsten reduction from APT to the addition of modified elements potassium, aluminum , silicon , and then sintering melt down , rotary forging process , coarse and fine tungsten filament in each step of the process . W31, W61, W91 , and WR15 new high-temperature tungsten filament :

W31

It has as excellent high temperature performance, reeling performance , to meet the energy-saving lamps , fluorescent lamps production use, Weihai polycrystalline material in 5 kg to provide a single , suitable for change pull factory. Grades from Japan , therefore , corresponds to the early use of filament capsule of the user.

W61

Equivalent grades of tungsten in Japan W31 performance and use, provides a single Weihai polycrystalline material in 5 kg , the same change for pulling factory. Grades from China's latest national standards.

W91

With excellent high temperature performance, can be used for high and low voltage halogen lamps , vehicle lights and high performance requirements of high prices on the tube and other fields.

WR15

It's a high -grade , high temperature, high shock tungsten wire, high temperature performance superior W91 grades for high color temperature , energy-efficient ( up C-class energy efficiency standards ) halogen incandescent lamp , is the material of choice for export to EU .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Lanthanum-Doped Tungsten Micro Advantages and Positive Effects

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:05

- Hits: 1632

Lanthanum -doped tungsten micro advantages and positive effects are :

1 Lanthanum -doped tungsten is added to a small amount of tungsten -doped lanthanum , changed the composition of doped tungsten , lanthanum doped tungsten micro cold resistance , heat resistance and other physical characteristics were compared with the conventional tungsten -doped greatly improved, the tests showed that micro- doped lanthanum tungsten cold, heat resistance than conventional doped tungsten are increased by 5 to 7%.

2 , The use of pressure guns lanthanum acid ammonia solution in spray form to be placed in the pot dopant doped tungsten blue spray , can effectively control the addition amount of lanthanum , tungsten is reached improve performance purposes , but also effectively reduce production costs, improve economic efficiency of enterprises .

3 , Increases in the later process of flame oxidation in air annealing step , the processing can effectively eliminate the hardened alloy , the alloy during processing to eliminate the internal accumulation of stress , tensile strength, lower tungsten , the tungsten wire the manufacturing more convenient.

4 , The production of micro- doped lanthanum by the addition of a small amount of tungsten lanthanum , thus changing the composition of the doped tungsten and internal grain size while eliminating the micro by oxidation annealing stress within tungsten doped lanthanum , therefore produced tungsten has a good seismic performance. Tests showed that using this method of production of micro- lanthanum -doped tungsten produced each 10 14V0. 1A0. 7CP bulbs, tungsten specifications for the 1. 0mg/200mm and 1. Ang/200mm, doped with tungsten in the same general seismic tests carried out under the conditions of contrast , the result is a specification of 1.2mg / / 200mm light bulbs, ordinary doped tungsten average number is 673 times the impact resistance , resistance to micro- doped lanthanum tungsten average impact of the number of 1233 ; specifications for a . 0mg/200mm bulbs , ordinary doped tungsten average number of 680 times the impact resistance , while the micro- doped lanthanum tungsten average number of impact-resistant 1209 times.

5, With a simple process, easy to implement and the advantages of low production costs , while the production of micro- lanthanum -doped tungsten has a long life , optical performance, strong seismic performance and a light bulb filament sag after use small amount of features.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micro-Doped Lanthanum Tungsten Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:00

- Hits: 1389

A micro- lanthanum -doped tungsten preparation method comprises the following steps :

( 1 ) The paratungstate in high purity hydrogen reduction furnace in pre- reduced blue tungsten ;

( 2 ) Wet incorporation of potassium silicate , aluminum nitrate solution , dried by stirring the mixture , the potassium, silicon, aluminum, tungsten adsorbed in the gap to obtain a doped tungsten blue ;

( 3 ) The use of pressure guns lanthanum acid ammonia solution in spray form to place the doped tungsten blue spray doping pot while stirring , until after spray drying, to obtain amino acid lanthanum doped tungsten blue ; < br />

( 4 ) The blue tungsten doped lanthanum acid into ammonia reduction furnace in high purity hydrogen reduction reaction to obtain a reduction of lanthanum tungsten alloy coarse powder ;

( 5) Reducing the tungsten alloy powder of lanthanum quantitative hydrochloric acid, hydrofluoric acid washing to remove the excess dopant and other impurities to obtain lanthanum tungsten alloy powder ;

( 6 ) Using isostatic press kit to install the elastic modulus of lanthanum tungsten alloy powder is applied to the equal force , made of uniform density tungsten billet ;

( 7 ) Hydrogen tungsten billet under the protection of pre- sintered to obtain a pre-sintered article ;

( 8 ) Pre-sintered in hydrogen under the protection of vertical melt sintering , melting sintering get vertical bar ;

( 9 ) Using the swaging equipment carried on the vertical melt sintering of forging, sintering of the vertical melt gradually reduced cross-section , the length increases, billet within the organizational structure of the tungsten grains and surface condition changes state to prepare tungsten rod ; < br />

( 10 ) Annealing the tungsten rod ; ( 11 ) the annealed then swaging tungsten rod having a diameter of 3.7mm tungsten rod ;

( 12 )On the turntable for coarse tungsten rod tension , tungsten rod through the die holes turntable after the cross section is reduced, increase in length , to obtain a crude tungsten wire ;

( 13 ) The crude tungsten in air by flame oxidation anneal , and after the coating of graphite and a small compression ratio, single stretch, eliminate work hardening and reduce the tensile strength filament ;

( 14) The crude tungsten single stretched via a plurality of the desired motif is drawn into thin tungsten wire. Moreover , in step ( 7 ) in the pre-sintering temperature of 1200 ~ 1400 ° C, sintering time 30 to 50 minutes.

Moreover , in step ( 3 ) in the vertical melt temperature of the final sintering sink 50 ~ ^ 50 ° C, the sintering time is 60 to 70 minutes to obtain the vertical melt density of sintered article 17. 2 ~ 17. 6g/cm3.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Potassium-Doped Tungsten Bulbs Basic Content of Reinforcement Theory

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:56

- Hits: 1775

Potassium foam reinforcement theory of the basic content includes three interconnected parts, which are :

(1) Potassium bubble formation and control. Tungsten oxide is added in trace potassium silicate , aluminum chloride mixed aqueous solution with hydrogen reduced to metal powder , and then compacts , sintering billet . Billet to form a large number of non-uniform distribution of the doping hole φ0.1 ~ 0.4μm . Analysis confirmed that potassium at room temperature to solidify the doped ionic pore walls , and tungsten have a coherent relationship . In the following rotary forging temperature , cold drawing and heat treatment process, the potassium -doped hole is flattened , elongated form along the filament axis orientation distribution of the " K tubes " or " K -line ." The greater the deformation process , the greater the aspect ratio of potassium tube . When annealed tungsten , potassium pipe expansion due to vaporization of potassium ( K boiling point of about 760 ℃), the temperature rose further instability potassium tubular shape , a split of the ovule , a bunch of potassium ordered bubble columns. Potassium tube split ovule instability of the process can be seen as a cylinder instability and approximate equation with perturbation theory and its potassium bubble dispersion model to establish quantitative expression equation, namely the establishment of the aspect ratio of potassium tube and the degree of deformation relationship L / W = (0.75 ~ 1.3) (Do / Dk) 4, ( wherein L, W, Do, Dk namely potassium tube length , width, diameter and tungsten rod original diameter after processing ) , and after dispersion derived The basic parameters of potassium bubble columns : bubble diameter potassium , potassium -containing foam bubble column number and spacing between two adjacent bubbles . Electron microscopic observation and experiment results calculated as consistent with each other . Experimental results and long-term production practice have shown that the necessary amount of potassium- doped hole is to ensure that the basis of potassium bubble dispersion , it depends on the additive potassium -doped tungsten optimum content ; while potassium and potassium bubble pipe split orderly diffusion model can control the degree of deformation and heat treatment through the system to reach . This design -doped Si, Al, K , and a reasonable amount of added processing to develop a reasonable degree of deformation and heat treatment system provides a credible scientific basis .

( 2 ) Potassium soak in the process of recrystallization behavior and mechanism of action . Along with the wire axis parallel to the direction of the ordered arrangement of potassium -doped tungsten bulb is caused by recrystallization behavior -specific basis . General material at an appropriate temperature after recovery and recrystallization processes , the formation of equiaxed grains without deformity . However , at high temperature to form doped tungsten filament axis direction along the particular aspect grow large particles , even cross-section of the wire is covered with 1 to 2 grains . It is this special grain boundary growth and finger overlapping grains , the tungsten doped with excellent high-temperature creep resistance , or anti- sag properties of tungsten . Ordered along the filament axis parallel to the direction of the distribution of potassium bubble column, a high temperature high vapor pressure within the bubble to bubble K corresponds to the second phase particles , strong pinning the grain boundary ( see Figure 1 ) , So a aspect suppress recrystallization , improves the recrystallization starting temperature , on the other hand to hinder the grain boundary migration radial filaments , and force it to move the wire axis , thus forming a special aspect of great growing grains ( see Figure 2 ) . The potassium bubble behavior and grain growth model has been a large number of experimental observations and theoretical calculations confirmed, but the details of its recrystallization processes and mechanisms are still not fully unified understanding. The focus of disagreement reply , primary and secondary recrystallization phasing and specific growth or soaring mechanism . Most people think that the first stage of recrystallization primary recrystallization in deformed grains gradually formed simultaneously coarse wire axis parallel to the series as the main feature of potassium bubble , but some people think it is the processing state of the Asian crude fiber bundles crystal ( see sub-structures ) polymerization grew up belonging to a polygon or restoration process . It was also defined as the in-situ re -crystallization process, the formation of the rod or sub-grain ; recrystallization grains elongated second stage is called overgrowth rapid growth or even covered wire cross-section of the main feature. However, this process is defined as the primary or secondary recrystallization still significant differences. Chinese scholar and his research group left Tieyong learn various scholars in the analysis based on the results , after years of systematic experimental and theoretical analysis , published a series of papers presented doped tungsten recovery and recrystallization nucleation mechanisms and recrystallization growth mechanism . The basic conclusion is that : first, the tungsten -doped high-temperature annealing occurs when deformed grains ( or fibers ) change phenomenon , is to resume the process of a special organizational change , grain boundary dissociation , Asia fiber aggregation caused by not once again crystallization behavior ; Second, because potassium bubble column grain boundaries and dislocations movement and its direction is strong pinning effect , resulting in a sub- fiber polymerization process proceeds very slowly and can be extended to temperatures above 2000K ; Third , doping the formation of abnormal grain growth in tungsten seemingly secondary recrystallization soaring organization, but experimental observations and theoretical calculations show that it is not the primary recrystallization occurs in a small number of matrix grain growth resumed , nucleation of new grains crystal growth and annexation of a few large new small recrystallized grains , and several other processes occur almost simultaneously complex process , based on deformation energy storage, grain boundary energy as the driving force , at different stages driven results can not simply traditional defined as the secondary recrystallization process .

( 3 ) Potassium bubble dispersion strengthening mechanism . Enhanced in a variety of materials, methods, dispersion strengthened (DS) is a second- phase strengthening , strengthening effect depends on the second phase of its chemical and thermodynamic stability , the ideal shape , small size , enough quantity and good dispersion . As a second phase of potassium bubbles all the conditions with the above , plus the size of the bubble and the dispersion K mode is controlled , but also shows the superiority of potassium bubbles , it has been classified as a number of dispersion strengthened in a distinctive strengthening mechanism . The second phase dispersion strengthened explain theoretical model matrix lot more is Orowan (Orowan) mechanism . Potassium bubble second phase particles as a special addition to causing diffusion rate decreases , increase the recrystallization temperature and thermal processing generate stable fibrous tissue and dislocation structures such as these Orowan strengthening indirectly strengthening mechanism , it must also see enhanced potassium bubble specificity, namely Asian organizations strengthening mechanisms . Ordered along the filament axis direction of potassium bubble column in processing fibrous form a distinct crystal growth , it is only at very high temperatures to form a clear long fibrous crystals and is very stable, and because of having abnormal , extreme aspect ratio large crystal growth and finger -shaped lock lap crystalline , less grain boundaries , especially grain boundaries transverse (perpendicular to the force of the grain boundaries ) less weakened creep at high temperatures plays a major role in the grain boundary sliding , thereby significantly improved tungsten -doped high-temperature creep strength. Research shows that the larger the aspect ratio , strength increase , the more significant aspect doped tungsten wire , usually above 20 . Experiments also showed that potassium bubbles on dislocation pinning attract and the more general second phase particles more powerful , its processing formed dislocation structure on the high-temperature strengthening greater role .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com