Molybdenum Disulfide-Based Fluorophore Preparation and Sensing Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 March 2022 23:05

- Hits: 1274

Recently, the State Key Laboratory of Organic Electronics and Information Display, Institute of Advanced Materials, Nanjing University of Posts and Telecommunications (NUPT), published a paper in the academic journal Biosensors (2022, 12) by the first author Lingbo Gong, introducing the preparation of molybdenum disulfide (MoS2)-based fluorophores and sensing applications.

Scientists Produce White Light Diodes without Rare Earths

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 March 2022 22:57

- Hits: 1313

A recent study mainly conducted by the researcher Velazquez report the development of white light diodes (WLEDs) by using rare earths free luminescent materials. The paper titled “Sunlike White Light-Emitting Diodes Based on Rare-Earth-Free Luminescent Materials” has been published in Materials 15(5), 2022.

Combining Sulfur and Molybdenum Fertilization Increases Antioxidant Capacity of Brown Goats

- Details

- Category: Tungsten Information

- Published on Sunday, 27 February 2022 21:40

- Hits: 1658

A team of researchers from the Southwest University of Science and Technology recently published a paper in Biological Trace Element Research on how a combination of sulfur (S) and molybdenum (Mo) fertilization can improve the antioxidant capacity of brown goats in South China.

Tungsten-Oxide-Based Material Applications

- Details

- Category: Tungsten Information

- Published on Saturday, 26 February 2022 22:44

- Hits: 1262

A research team from the Taiwan University of Science and Technology has published a paper in Frontiers in Materials on the progress of tungsten-oxide-based material applications. Tungsten-oxide-based material has received great attention due to its ability to absorb near-infrared (NIR) light and its efficient photothermal conversion properties.

Structure and Morphology of Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Thursday, 24 February 2022 21:54

- Hits: 1220

The research team at Yingkou Institute of Technology and Georgia Institute of Technology recently presented their latest work describing the structure and antimicrobial properties of thin-film coatings based on tungsten oxide materials on stainless steel substrates.

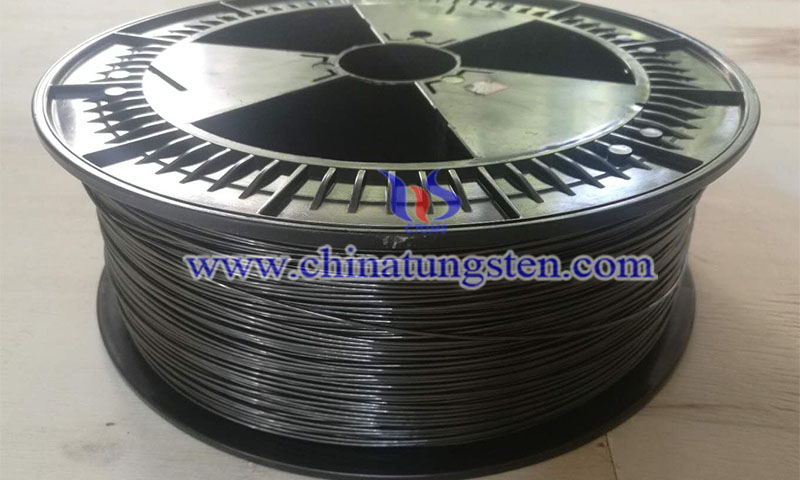

Molybdenum Wires’ Types and Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 February 2022 22:44

- Hits: 1235

Molybdenum wires are common molybdenum product. If classified by material, molybdenum wire can be divided into pure molybdenum wire, high-temperature molybdenum wire, sprayed molybdenum wire, and wire-cut molybdenum wire and different types of molybdenum wire have different characteristics and their applications are also varied.

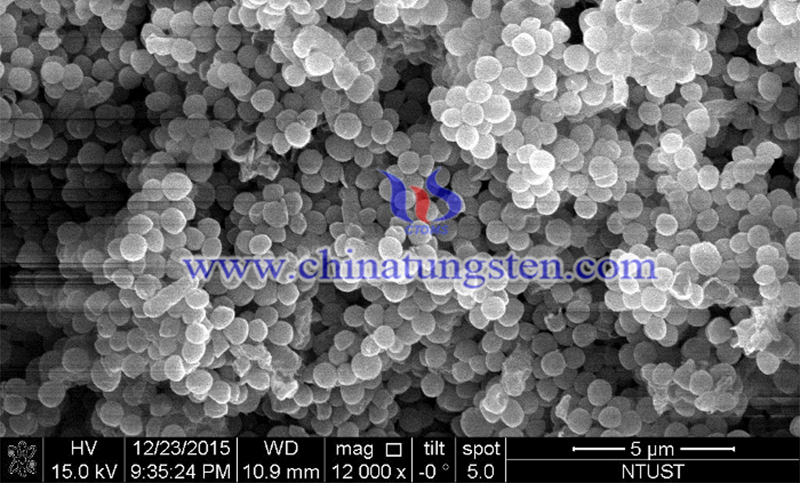

Sodium Tungstate Particles’ Characterizations and Morphology

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 February 2022 22:09

- Hits: 1258

In organic chemistry, sodium tungstate (Na2WO4) is used as a catalyst for the epoxidation of alkenes and the oxidation of alcohols to aldehydes or ketones, and sodium tungstate particles are also known for their anti-diabetic effects; researchers have identified pathways by which sodium tungstate improves pancreatic function and beta-cell proliferation.

Information About Tungsten

- Details

- Category: Tungsten Information

- Published on Saturday, 19 February 2022 18:54

- Hits: 1306

Tungsten (W) is a durable, strong metal used to make rings and other jewelry. The word tungsten originates from the Swedish word meaning heavy stone. It is a steel-gray material with the highest strength of any known metal, and it’s only one point lower than diamond on the Mohrs Hardness Scale.

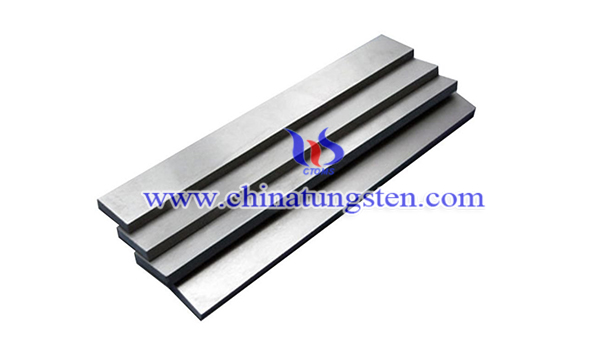

The Advantages of Tungsten Alloy Applied in Medical Shielding

- Details

- Category: Tungsten Information

- Published on Thursday, 10 February 2022 22:58

- Hits: 1235

Tungsten alloy has the advantages of high density, machinability, good corrosion resistance, and high radiation absorption capacity, and high strength. It is widely used in the fields of aerospace and automotive industries and radiation shielding.

Molybdenum Improves Cathode Materials’ Performance in Li Batteries

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 February 2022 23:06

- Hits: 1231

A study at the University of Queensland has shown that tungsten and molybdenum (Mo) can improve the electrochemical properties of the cathode materials in Li batteries. As the driving range of electric vehicles increases, more nickel is needed to increase energy density, but this also reduces cycle stability. Tungsten and Mo improve stability by enhancing structural stability and resistance of the cathode material surface layer to electrode/electrolyte side reactions.

sales@chinatungsten.com

sales@chinatungsten.com