Hyperion Metals Could Be A Major Player in US Rare Earth Supply Chain

- Details

- Category: Tungsten's News

Hyperion Metals Limited has achieved significant results from its rare earth concentrate flotation test, highlighting the potential for west Tennessee to become a major source of conventional and sustainable rare earth minerals, and for the company to become a major player in the US rare earth supply chain. Hyperion Metals' rare earth concentrate flotation test work has established 97% total rare earth mineral recovery at its Titan project in Tennessee, USA.

The company's test results indicate that successful flotation of rare earth minerals as a preliminary processing stage offers significant potential benefits for future mineral separation plant design, including: a more streamlined design compared to the separation of rare earth minerals in the later processing stages; and reduced potential contamination of downstream products, including titanium and zircon.

Hyperion says extracting high-value rare earths as an initial processing stage allows for selective product strategy and plant development, including phased capital development.

Anastasios Arima, the company's Managing Director and CEO, said, "These latest results are a significant event in the development of Hyperion's mineral business. The test work highlights the potential for simple separation of front-end rare earth concentrate product streams, and thus significant optionality in process flow sheet design."

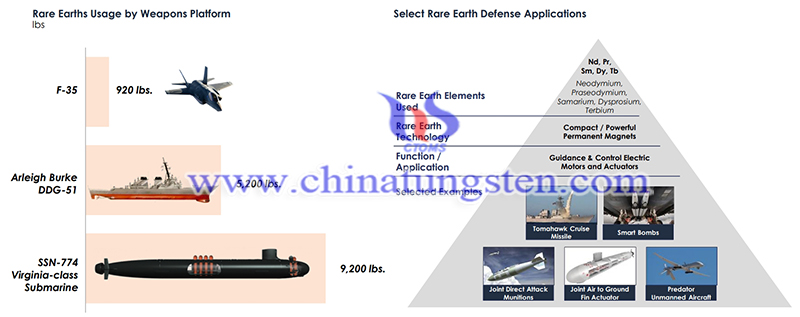

"These test results and the recently announced first mineral resource estimate further demonstrate Hyperion's outstanding potential to develop a major source of critical mineral supply in West Tennessee. The test results are consistent with test work conducted in August, with neodymium and praseodymium accounting for 21.3 percent of the rare earths and high-value terbium and dysprosium accounting for 1.9 percent of the rare earths."

At current spot prices, the potential average price for rare earth oxide products is approximately US$50,000 per ton. Heavy mineral concentrate (HMC) was generated using conventional feed preparation and wet gravity separation, with a final stage upgrade using a spiral and wet shaking table.

The rare earth stream is further upgraded on a wet shaker table to increase the final rare earth mineral concentrate concentration, and the HMC stream is treated on a wet shaker table and then processed through a conventional mineral separation process, with flotation expected to be completed around the end of November.

Based in the US, Hyperion Metals aims to be a leading developer of zero-carbon, sustainable, critical materials supply chains for industries including space, aerospace, electric vehicles, and 3D printing, and the company would be a potential major player in the US rare earth supply chain.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com