Tungsten Carbide V-CUT Knife Precautions for Use

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:18

- Written by xjq

- Hits: 612

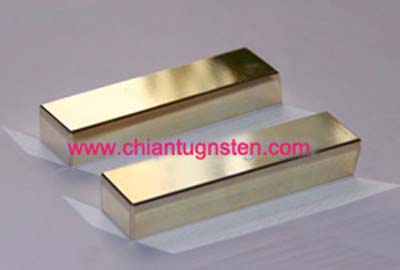

Tungsten Gold Plated Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 09:42

- Written by Sherry

- Hits: 597

Tungsten gold plated bar is bar made of tungsten and plated by gold. They are widely used as substation of gold bar as memento, jewelry and so on.

Tungsten gold plated bar has the properties of tungsten, which are high density, durable, hardness, oxidization resistance, and weak radioactive. What’s more, tungsten gold plated bar is environmental-friendly, which has been a reason for the popularity of people all over the world.

Tungsten gold plated bar has the surface of gold, which is smooth and bright as copper mirror, and able to reflect the images which are next to it. They are gold color, which is attractive and pleasant to eye.

Tungsten gold plated bar can be not only manufactured with gold plated only, but also with letters engraved on it. And the letters can be chosen by customers or engraved according to customers’ drawings.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Punching Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2014 17:15

- Written by xjq

- Hits: 637

Tungsten carbide punching rod as an essential accessory in cold-heading Dies has many different types such as round punching rod, square punching rod, hexagonal punching rod, etc., mainly used for molding and drilling. There are more and more enterprises expect higher about the improvement of punching rod service life. Tungsten carbide rod is then born at the right moment. Tungsten carbide itself has good physical properties, high abrasion and impact resistance, which makes it become a good material for cold-heading dies.

Tungsten carbide round rods are often used in hole leading and punching, while tungsten carbide square rods are often used as nut punching rods.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide V-CUT Knife Common Specifications

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2014 18:01

- Written by xjq

- Hits: 631

Tungsten carbide V-CUT knife is mainly made from tungsten carbide, which is also known as tungsten steel. Therefore, this kind of knife is also called solid tungsten steel V-CUT knife. It is a kind of electronic cutting tools commonly used in the production of circuit board, and there are six main product specifications:

No. OD × ID × thickness teeth number angle

I. φ56.3 × φ25 × 2.4, 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

II. φ51.3 × φ25 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

III. φ51.3 × φ25 × 2.0, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

IV. φ39.5 × φ17 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

V. φ32 × φ17.5 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

VI. φ28 × φ15 × 2.0, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °.

Tungsten carbide V-CUT knife with advantages of high hardness, strength and abrasion resistance as well as long service life can significantly improve productivity.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Surface Roughness

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2014 17:00

- Written by xjq

- Hits: 562

The roughness of tungsten carbide rod may to a certain extent affect the processing quality. There are four main factors that may affect its roughness.

1. Grain size of grinding wheel

The grinding of tungsten carbide rods is generally divided into two or three steps, the first several steps of which provide accurate grinding while the last step provides coarse grinding. The higher the granularity of grinding wheel is, the finer the emery particles are, and also, the texture will be finer and products will be brighter in the naked eyes.

2. Revolving speed of grinding wheel

The faster the grinding wheel revolves, the shorter the time it rubs with tungsten carbide rod, and naturally, the chance to cause textures in tungsten carbide rods will be smaller.

3. Concentration of grinding lubricant

Grinding lubricant is a kind of auxiliary material in the processing of tungsten carbide rod, but it will affect the roughness of tungsten carbide rod whether its concentration is too low or too high.

4. Grain size of tungsten carbide rod

Tungsten carbide rod is composed of many small and large particles. The finer the particles are, the smaller the gap between each other is and the better the compactness of products is. What is more, polishing process will also be easier.

In addition to the above factors, human factor is also very important. Only when operators are more careful and professional, will the tungsten carbide rods be better produced.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com