China Molybdenum Price - May 4, 2023

- Details

- Category: Tungsten's News

- Published on Thursday, 04 May 2023 18:53

- Written by Shuxia

- Hits: 652

China molybdenum price stabilizes in the first trading day after the holiday of Labour Day as most participants do not totally come back from the holiday. At present, the industry is focusing on the shipment situation of molybdenum mining enterprises and the bidding situation of steel enterprises.

Self-Passivating Tungsten Alloys and Surface Coating Protection Technology

- Details

- Category: Tungsten's News

- Published on Tuesday, 02 May 2023 17:26

- Written by Caodan

- Hits: 781

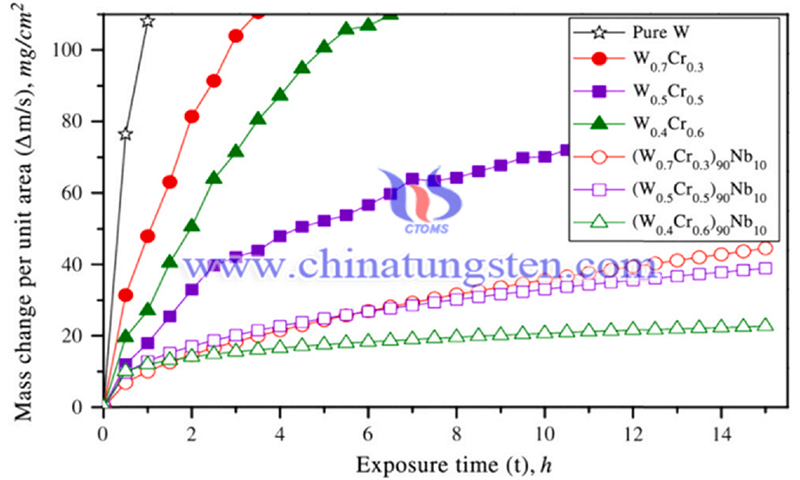

In order to solve the problem of poor oxidation resistance of W and W-based alloys at high temperatures, this work gives self-passivating tungsten alloys and surface coating protection technology. Optimization of the preparation process of the alloy (heat treatment of HIPed alloy, etc.) can effectively reduce or eliminate its internal cracks and holes, thermal stresses and residual stresses, thus reducing its surface roughness and porosity. In addition, some beneficial elements (Ti, Zr, Y, Nb, etc.) can be added to improve the high-temperature strength of W-based alloys, slow down the diffusion of Cr cations, and promote the formation of oxide films.

Read more: Self-Passivating Tungsten Alloys and Surface Coating Protection Technology

Si-WSi2 Coating Prepared by HDS

- Details

- Category: Tungsten's News

- Published on Monday, 01 May 2023 12:27

- Written by Caodan

- Hits: 695

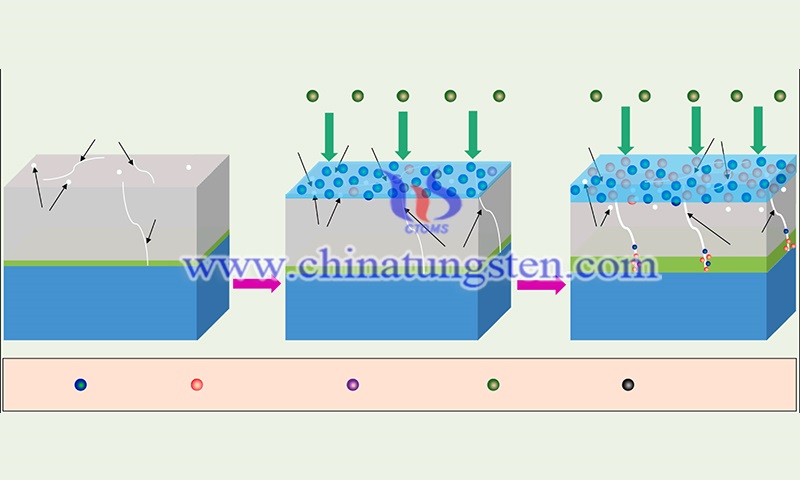

Zhang et al. prepared Si-WSi2 coatings on W substrates by hot-dip silicon-plating (HDS) technique. The HDS method involves placing a solid infiltration source into a corundum crucible under a high-temperature protective atmosphere, heating it until it is completely melted, and maintaining the temperature for a certain period of time. The processed sample is then slowly placed into the crucible and the coating is formed on the surface of the substrate by interpenetration between the substrate and the melt. This method is considered to be a cost-effective coating preparation method, which features short coating preparation time, high deposition temperature, uniform coating composition, smooth surface, and compact structure.

Effect of Coating Preparation Method on Oxidation Behavior of W-Based Materials

- Details

- Category: Tungsten's News

- Published on Tuesday, 02 May 2023 17:17

- Written by Caodan

- Hits: 701

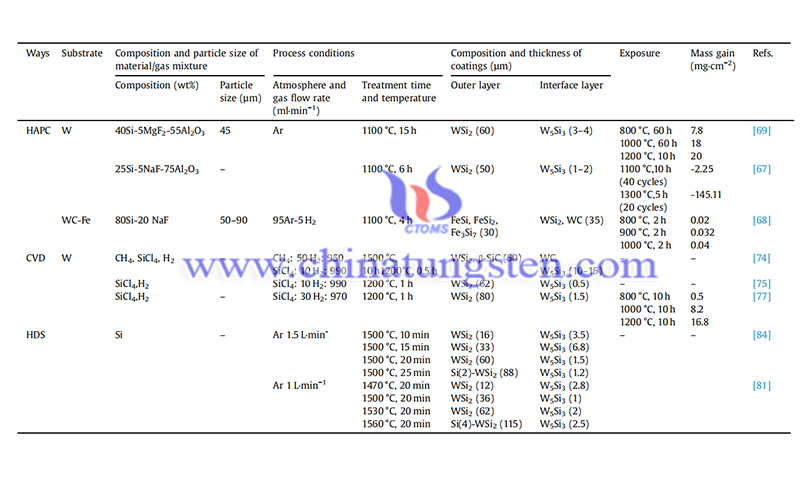

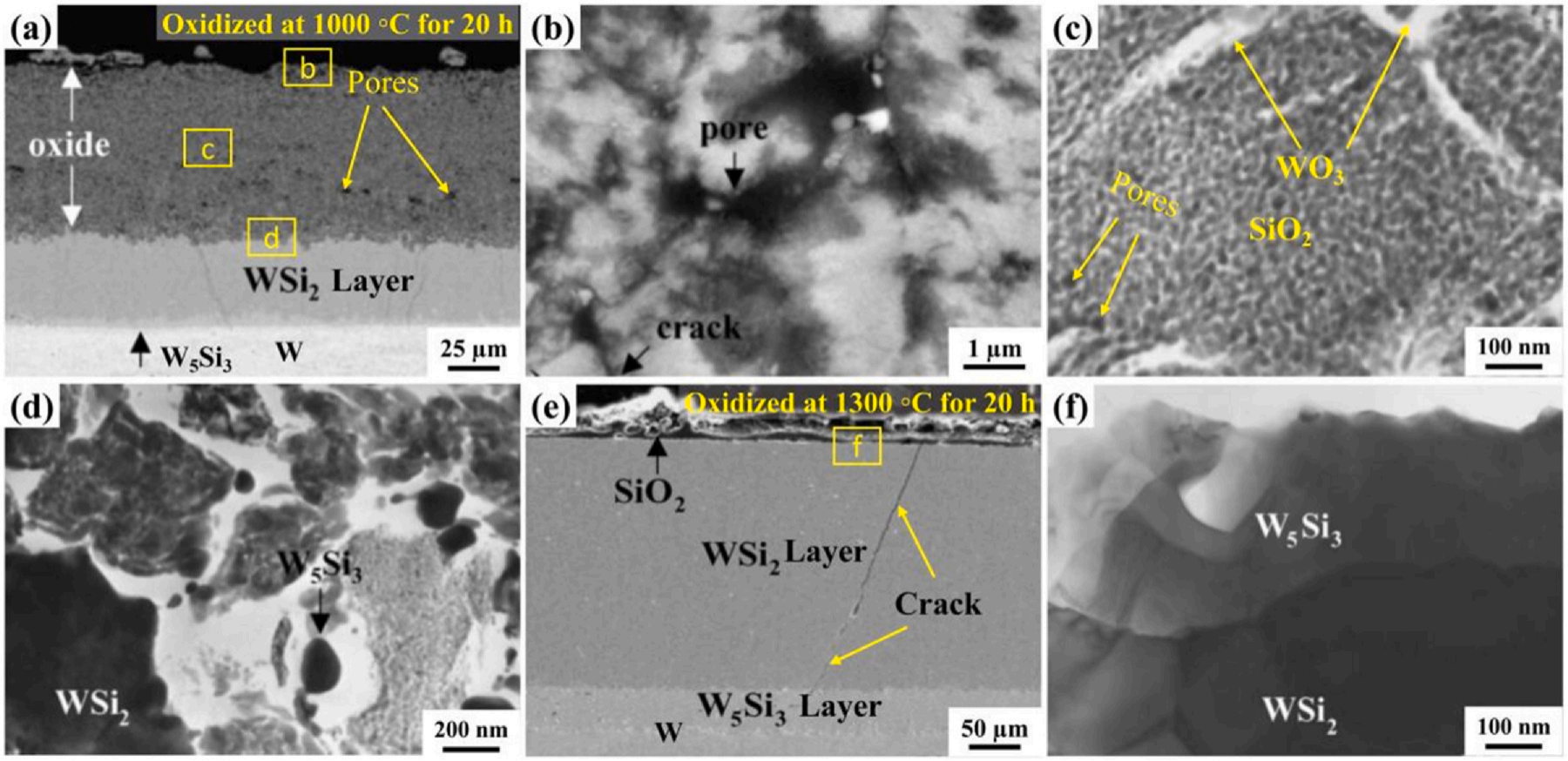

Researchers summarize the effects of different coating preparation methods on the coating composition and oxidation behavior of W-based materials. It can be seen that the silicide coating consists mainly of a thick WSi2 layer and a thin W5Si3 layer. The HAPC coating requires a longer time due to the relatively low diffusion temperature. After 4~15 hours of treatment at 1100 °C, the thickness of the coating is only 30~60 µm. However, using CVD technology, the thickness of the coating can reach 50~80 microns after 0.5~1 hour of deposition at 1200°C. In contrast, the HDS technique is very efficient for coating preparation. By depositing at 1500°C for 0.25~0.42 h, coatings with thicknesses of 36~88 µm can be obtained.

Read more: Effect of Coating Preparation Method on Oxidation Behavior of W-Based Materials

WSi2/β-SiC Nanocomposite Coating Prepared by CVD

- Details

- Category: Tungsten's News

- Published on Monday, 01 May 2023 12:20

- Written by Caodan

- Hits: 686

The WSi2/β-SiC nanocomposite coating were obtained by a two-step chemical vapor deposition (CVD) process. EPMA results showed that the carbide coatings consisted of a WC layer and a W2C layer with corresponding thicknesses of 2 and 17 µm, respectively. The WSi2 layer with a thickness of about 50 µm was then obtained by silicification at 1200 °C for 30 min.

sales@chinatungsten.com

sales@chinatungsten.com