How to Make Tungsten-based Diamond Grinding Wheel

- 詳細

- カテゴリ: Tungsten Information

- 2019年2月28日(木曜)22:37に公開

- 参照数: 2257

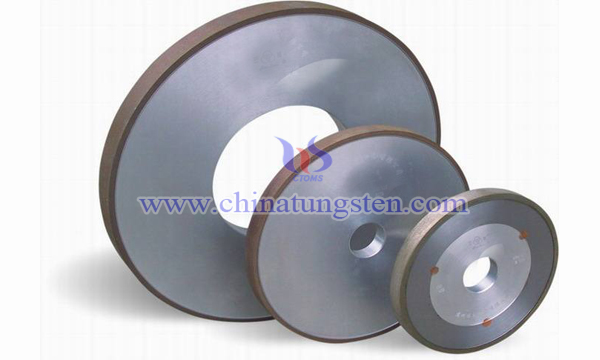

Diamond grinding wheels are widely used in the efficient processing of low iron content metals and hard and brittle materials, such as cemented carbides, high alumina ceramics, optical glass, agate gems, semiconductor materials and stone materials.

The melting point of tungsten is as high as 3410 ℃. The sintering temperature of tungsten as a metal bond is much higher than that of diamond. It is easy to lead to graphitization of diamond particles. Therefore, how to crack the problem of high sintering temperature of bond will open a new door for the manufacturing technology of diamond grinding wheel. Some researchers think of adding rare earth.

The diamond powder is fully mixed with rare earth modified tungsten-based binder. The rare earth modified tungsten-based binder contains the following components: tungsten 40-75 phr, nickel 2-6 phr, iron 2-5 phr, tin 8-30 phr, copper 7-20 phr, manganese 0.4-1 phr, rare earth lanthanum 0.1-1 phr.

1.According to the shape of the diamond sand tire body, the mixture was cold-pressed by the corresponding die and then sintered by vacuum hot pressing. The sintering temperature was 900-960 ℃, the sintering pressure was 140-200 KN, and the sintering time was 25-35 minutes.

2.After vacuum hot pressing sintering, the diamond sand tire body was obtained by hot isostatic pressing sintering, sintering temperature 840-900 ℃, sintering pressure 80-120 MPa and sintering time 5-10 minutes.

3.The diamond grinding wheel is obtained by attaching the diamond tire body to the grinding wheel base.

Due to the addition of lanthanum, rare earth and tungsten components complement each other. The sintering temperature is reduced from nearly 4,000 degrees Celsius to the acceptable range of diamond. The shortcomings of tungsten-based binder which is difficult to be applied in practice due to the high sintering temperature are solved. The manufacture of tungsten-based diamond grinding wheel is successfully realized. The chemical-metallurgical bonding force produced by the reaction between tungsten and diamond is utilized to improve the diamond quality. The grip force of diamond particles on Diamond tire body leads to high hardness and wear resistance of diamond grinding wheel, which opens up a new situation for the manufacture of high performance diamond grinding wheel.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com