How to Synthesize Tungsten Titanium Composite Nanofibers

- 詳細

- カテゴリ: Tungsten Information

- 2019年2月26日(火曜)23:30に公開

- 参照数: 2288

Titanium dioxide is a broadband semiconductor material, which is often used to photocatalytic degradation of organic pollutants in gases or liquids. However, it is well known that titanium dioxide is not efficient enough to degrade pollutants in the environment. This is mainly because its wide band gap semiconductor can only respond to the ultraviolet band of sunlight, while ultraviolet light accounts for only 3%-5% of sunlight, which greatly limits the utilization of titanium dioxide to sunlight.

In order to improve the degradation efficiency of titanium dioxide and the utilization of sunlight, researchers have made a series of experiments on titanium dioxide, such as doping, compounding and surface modification of precious metals. Tungsten trioxide is also a kind of N-type semiconductor material. It is found that the photocatalytic activity of tungsten trioxide can be greatly improved by the effective combination of titanium dioxide and tungsten trioxide. In order to further enhance its effect, some scholars have prepared a tungsten titanium composite nanofibers, which have low cost and good performance. The synthesis process is as follows:

(1) Configuration of spinning solution

At room temperature, soluble titanium salts were added into the mixed solvent of anhydrous ethanol and acetic acid, stirred for 1-3 hours, then added soluble tungsten salts, stirred for 1-3 hours to obtain the reaction solution A; PVP solution B was obtained by dissolving PVP in anhydrous ethanol and stirring for 2-4 hours; acetone, N-N dimethylformamide (DMF) and acetylacetone were mixed to obtain organic solvent C;

When the reaction solution A and PVP solution B were mixed, a viscous cross-linking substance was formed immediately. Then the organic solvent C was added to the cross-linking substance. The cross-linking substance was dissolved and stirred for 2-4 hours to obtain the spinning solution, in which the mass concentration of PVP in the spinning solution was 5%-15%.

(2)Electrospinning

The above spinning solution is spinned at a voltage of 0.8-20,000 volts, the flow rate of the micro-propellant pump is 5-20 ugL/min, and the distance between the spinneret and the receiving device is 8-20 cm. The PVP non-woven fabric containing titanium and tungsten precursors is obtained.

(3) Follow-up heat treatment

The above PPV nonwoven fabrics were calcined at 450 - 550 ℃, and the organic matter in the fabrics was burned off to obtain tungsten titanium composite nanofibers.

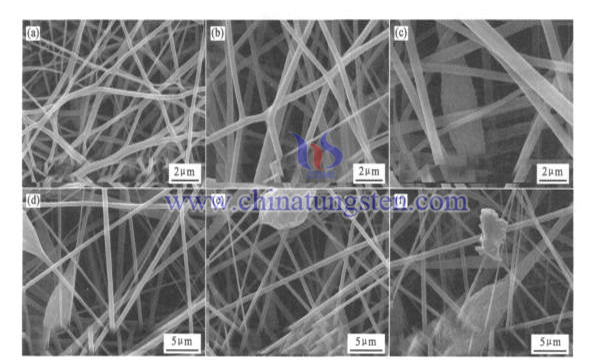

Under electron microscopy, the composite nanofibers have regular morphology, uniform particle size and high specific surface area, which can be used to prepare photocatalysts, dye-sensitized solar cells and so on.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com