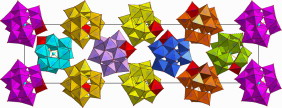

The structure of ammonium metatungstate

- 詳細

- カテゴリ: Tungsten Information

- 2015年2月02日(月曜)13:47に公開

- 参照数: 1892

The structure of ammonium metatungstate powder is highly dependent on hydration and POM molecule rotation, with cation and hydrogen bonding forces directing a mixture of structure that have been studied with bulk and single-crystal methods. The illustration show simulated anion structural disorder that the fully dehydrated form of the compound.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Bar Introduction

- 詳細

- カテゴリ: Tungsten Information

- 2014年9月19日(金曜)15:12に公開

- 参照数: 1910

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Development Process of GW Series High-Density Tungsten Alloy

- 詳細

- カテゴリ: Tungsten Information

- 2014年9月18日(木曜)11:23に公開

- 参照数: 2100

During the 1970s and 1980s, China's development and stereotypes produced three high-density tungsten alloy, and passed technical appraisal, armor-piercing bomb core material obtained as a successful application.

1.GW-1 alloy

GW-1 alloy is developed based on domestic raw materials for the first generation of tungsten alloy bomb core material, its main features are: (1) adding a small amount of elements made of reinforced multicomponent alloys in W-Ni-Fe system, make this alloy has good sintering properties, no significant deflection after sintering, without the need for additional post-processing can achieve certain mechanical properties. (2) liquid-phase sintering process using powder metallurgy and easy process. (3) has good mechanical and physical properties, its main performance and the level of foreign alloy is quite similar, and has good machining properties.

GW-1 alloy from research to production in less than five years, the formation of the first generation of tungsten alloy bomb core material to fill the gaps in our tungsten alloy penetrators, laying the development of high muzzle velocity, high chamber pressure tungsten alloy armor-piercing bomb core material basis.

2.GW-2S high-density tungsten alloy

GW-2S alloy developed in the first generation of tungsten alloy penetrators on the basis of material up a high-density, high ductility, moderate strength alloys, it is to meet the high muzzle velocity, armor piercing high chamber pressure conditions in the semi-steel sleeve By using and developed a bomb core material. High density tungsten alloy can be heat treated, especially the use of vacuum heat treatment can improve the strength and ductility. But studies show that this heat treatment is only within a certain range of alloy composition to achieve good results. For this reason, studied the relationship between the heat treatment changes in Ni / Fe ratio, the further adjustment of the various process parameters to obtain a GW-2S alloys.

3. GW-3S high density tungsten alloy

With the high muzzle velocity kinetic energy penetrators, high chamber pressure, large slenderness ratio, and rely entirely on the strength of bomb core material itself to withstand high-speed transmission and ensure the normal development of the direction of flight of armor-piercing tungsten alloy material with more demanding, not only have high strength and high toughness and have a good dynamic. To do this they developed a GW-3S alloys. Through research, the better the traditional powder metallurgy and metal processing technology combined with modern, more comprehensive use of advanced scientific and technological achievements, so that the GW-3S alloy has a major breakthrough in terms of strength properties.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Uses of tungsten

- 詳細

- カテゴリ: Tungsten Information

- 2014年9月15日(月曜)16:21に公開

- 参照数: 1860

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Characteristics of Advanced Tungsten Bullets

- 詳細

- カテゴリ: Tungsten Information

- 2014年9月10日(水曜)15:49に公開

- 参照数: 1963

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Brief Introduction of W-Re Thermocouple

- 詳細

- カテゴリ: Tungsten Information

- 2014年9月03日(水曜)16:48に公開

- 参照数: 1899

| W Re, (Positive) | W Re, (negative) | |||

| Element | Re | W | Re | W |

| Content,wt% | 3.00 | balance | 25.00 | balance |

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

New Tungsten Carbide Boring Head's Characteristics

- 詳細

- カテゴリ: Tungsten Information

- 2014年7月23日(水曜)17:43に公開

- 参照数: 1927

When tungsten carbide boring head’s cutting is in high-speed machining, high-speed rotating imbalance tungsten carbide boring head, centrifugal force and tungsten carbide boring head itself can cause large vibrations, thereby damaging the sensitive display device. The new tungsten carbide boring head by using a balancing mechanism that can reduce or eliminate unwanted vibration at high speed boring. With a digital readout screen, precision boring heads have been able to speed up 16000r/min speed boring.

New tungsten carbide boring head’s digital display shows the direct displacement of the slider of the boring tool, without having to determine the amount of displacement by adjusting the amount of rotation of the screw blade. As the boring bar boring tool mounted directly on the slider, so the number of significant readings tungsten carbide boring head can truly reflect the displacement of boring tool, and is not affected by the screw backlash errors. Digital tungsten carbide boring head this feature so that it can more quickly and precisely adjust the bore diameter, and can realize the error compensation process deviations or tool wear.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten carbide products

- 詳細

- カテゴリ: Tungsten Information

- 2014年7月16日(水曜)17:48に公開

- 参照数: 1943

Tungsten is a silvery white metal, melting point up to 3400 ℃; great hardness of tungsten, high-density, high temperature strength. Tungsten and tungsten carbide mainly used in the production of iron. Tungsten and chromium, molybdenum, cobalt and other components for the production of heat-resistant alloy cutting tools, metal surface hardening material, lit pull blades. Tungsten, tantalum, niobium, molybdenum, refractory alloy composition. Tungsten, copper and silver alloys for the production of tungsten light bulbs, components and arc welding electrode tube. Some of the compounds can be used tungsten fluorescent agents, pigments, dyes and the like. Tungsten is widely used in oil and gas, mining, electronics, metalworking, machinery, heavy manufacturing, these sectors make use of tungsten 85% of the total, the other is applied to nuclear and aerospace industries. With economic development, technological advances, China tungsten applications are gradually expanding, increasing product variety, great to meet the needs of the national economy and national defense construction.

Carbide is an inorganic compound which contains equal numbers of tungsten and carbon atoms. It may also be colloquially referred to as "carbide." In its most basic form of a gray powder, but can be press-formed into various shapes, for industrial machinery, tools, abrasives, even as jewelry. Carbide, also belong to heavy metals, the bending strength is more good than any other, including iron and steel, including metal or alloys. Because of its high resistance to abrasion, wear and tear is to produce a variety of utensils ideal choice. Generally, carbide parts mainly for the metal processing industry, which stresses a strong tool. However, the high bending strength and wear resistance of cemented carbide also features the use of many non-metallic solution provides a cost effective, such as: crushing, grinding stones. Carbide is mainly used for wear demanding applications, such as: drilling, milling, trenching and cutting.

Carbide Parts Features: high hardness (86 ~ 93HRA, equivalent to 69 ~ 81HRC); hot hardness (up to 900 ~ 1000 ℃, keeping 60HRC); wear resistance. Such as: 4 to 7 times higher than the carbide parts high-speed steel cutting tools, tool life of 5 to 80 times higher. Manufacture of molds, gauges, life expectancy of 20 to 150 times higher than the alloy tool steel. 50HRC be about cutting hard materials. But brittle carbide parts, cutting can not be performed, a complicated shape is difficult to produce a solid tool, often made of blades of different shapes, or a die cutter body using welding, bonding, mechanical clamping, in particular a method for installing such to use.

Carbide tools are widely used in machinery and engineering industries. Our company offers a variety of high-quality, long performance, life cycle carbide cutting tools such as carbide inserts, indexable inserts, rotary burrs, carbide saw blades, carbide cutters, etc., but also can produce different types of carbide cutting tools according to customers' requirements or drawings.

Carbide Rods in grades YG10X mostly used in drill bits, end mills, reamers. YG6X for non-ferrous precision cutting. Ultrafine grain size YG8X used in the processing of glass, steel, titanium, hardened steel, etc.

Carbide material in one of the many, because the shape of a rectangular plate (or box) named, also known as carbide strip plate. Carbide long mainly by WC WC and Co cobalt powder metallurgy method by using a mix of flour, milling, pressing, sintering, the main component of the alloy WC and Co, different uses of WC carbide strip ingredients and Co are not consistent, the use of a very broad range.

Carbide has excellent long been rigid, high hardness, wear resistance, good high elastic modulus, high compressive strength, chemical stability (acid, alkali, high temperature oxidation), low impact toughness, coefficient of expansion low thermal conductivity of iron and its alloys with similar characteristics. Processing of solid wood, MDF, gray cast iron, non-ferrous materials, chilled cast iron, hardened steel, PCB, mainly used in the production of brake material. Specific material should be used to select the appropriate long carbide according to purpose.

Commonly known as tungsten carbide ball ball refers to material carbide beads, ball. Carbide ball / tungsten ball high hardness, wear resistance, corrosion resistance, anti-bending, harsh environments, can replace all the steel ball products. Tungsten balls with high hardness, wear resistance, corrosion resistance, anti-bending characteristics, can replace all the steel ball products. Tungsten ball extremely broad scope, such as: precision bearings, instruments, meters, pens, spraying machines, pumps, machinery parts, valve seals, brake pump, squeeze hole punch, oil, hydrochloric acid, laboratory, hardness measuring instrument, fishing gear , weight, decoration, finishing, etc. high-end industries.

Tungsten products manufacturer, supplier: Tungsten Online Technology Co., Ltd. Product Details view: http://www.chinatungsten.com

Order Tel 0592 -5129696 Fax 0592 -5129797 E-mail: sales@chinatungsten.com tungsten and molybdenum library: http://i.chinatungsten.com Tungsten News, price mobile site, 3G version: http://3g.chinatungsten. com news molybdenum, molybdenum price: http://news.molybdenum.com.cn public concern micro-channel number "tungsten line" for daily updates of tungsten and molybdenum prices

Tungsten Alloy Skinny Dropshot Weight

- 詳細

- カテゴリ: Tungsten Information

- 2014年7月07日(月曜)16:55に公開

- 参照数: 1829

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Hardness And Toughness of Tungsten Carbide Cutting Tool

- 詳細

- カテゴリ: Tungsten Information

- 2014年7月04日(金曜)18:25に公開

- 参照数: 1963

Tungsten carbide is the most widely used type of high speed machining (HSM) cutting tool material, this kind of material is produced by powder metallurgy process, and consists of hard carbide particles (usually a tungsten carbide WC) and the soft metal bond. At present, there are hundreds of different composition of WC cemented carbide, where cobalt (Co) are used as the binder, nickel (Ni) and chromium (Cr) is also a common bond element. In addition, you can also add other alloying elements. Why there are so many carbide grades? Cutting tools manufacturers how to select the right cutting tool material for a certain cutting machining?

The hardness and toughness WC-Co tungsten carbide has the unique superiority in both hardness and toughness. Tungsten carbide (WC) itself has the very high hardness (more than corundum or aluminum oxide), and its hardness is rarely drop when work temperature become higher. However, it lacks enough toughness, which is essential for a cutting tool performance. In order to use the high hardness of tungsten carbide, and improve its toughness, people will use metal bond tungsten carbide together, so that the material has far more than the hardness of high speed steel, at the same time, it can withstand cutting force in most machining. In addition, it also can withstand the cutting heat generated by high speed machining.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com