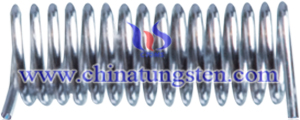

Anti-Sag Tungsten Wire Performance

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 20:00

Tungsten at a certain temperature and a certain resistance to their sagging under load deformation capacity. Anti-sagging properties of the material is actually a reflection of high temperature creep resistance, which is doped with tungsten is a very important performance indicators.

Tungsten filament incandescent bulbs and a vacuum device, its working temperature is usually above 2000 ℃, so the effect of high temperature and tungsten weight, since the material strength is decreased and the grain boundary sliding and produce sag. To ensure that the shape of the filament at a high temperature and dimensional stability, requires tungsten must have good high temperature sag resistance capability. This capability and the recrystallization temperature of tungsten grains after recrystallization geometry closely related. For doped with potassium, aluminum, silicon, tungsten wire, because of its high recrystallization temperature, and recrystallized to form a large aspect ratio of recrystallized grains, and between the grains was dovetail lap, this structure makes the most of the grain boundary is parallel or nearly parallel axes wire, which significantly improves the ability of the tungsten filament temperature sag resistance.

Tungsten-doped high-temperature sag resistance capacity, mainly by the potassium tungsten bulb size, number, and distribution (dispersion state) is determined, and the dispersion state of the bubble in addition to potassium and potassium in the outside, suitable deformation and heat treatment system is essential, the former is the ability to obtain a prerequisite for sag resistance, and the latter is a necessary condition.

Determination of anti-sag tungsten wire performance in many ways, a common high-temperature creep test method, high flexural droop method (V-shaped test) and so on. Service conditions from the point of view of the filament, sagging test method than the creep test method using tungsten better meet the actual situation. Thus creep test method is gradually being replaced by sagging test for detecting anti-sag tungsten high temperature performance.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com