WO3-TiO2 Photocatalysts with Enhanced Photocatalytic Properties

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 September 2021 00:23

In the past decade, the application of semiconductor powder as a photocatalytic degradation of organic pollutants in water has received widespread attention. Titanium dioxide (TiO2) suppresses amazing photocatalytic properties, including high activity, chemical stability, and low cost. However, the photocatalytic activity of TiO2 (with a band gap of 3.2 eV, excited by photons with a wavelength of less than 387 nm) is still limited by UV wavelength irradiation, so the photocatalytic process cannot effectively occur during sunlight irradiation. 4% of the total solar spectrum radiation is in the ultraviolet region.

WO3-TiO2 photocatalysts with enhanced photocatalytic properties have been synthesized from ammonium paratungstate, the photocatalytic property has been largely improved under visible light. The synthesis steps are as follows:

TiO2 (P25), titanium tetrachloride (TiCl4, 98%), tungstic acid (H2WO4, 99%) and ammonium paratungstate (APT, >99%) were used without further purification. The pollutant model is salicylic acid (SA) (C7H6O3, ≥98%).All coupled titanium dioxide samples are deposited on a substrate, which is composed of a 4 cm × 48 cm ordinary glass plate. The substrate is first pretreated with dilute nitric acid and washed with NaOH solution to increase the density of OH groups on the glass surface, thereby enhancing the binding of TiO2, then rinse with distilled water, and finally dry.

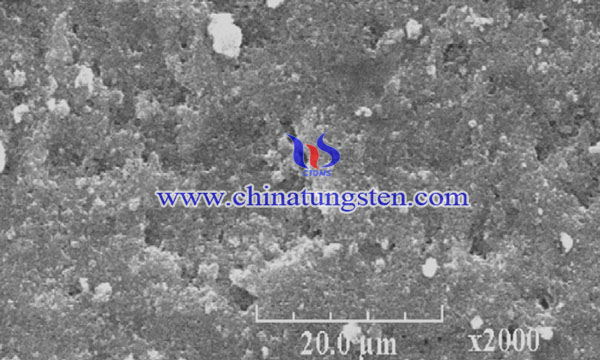

TiO2 is coupled via WO3 and deposited according to three different procedures: TiO2-powder (P25 Degussa, 4 g L-1) was suspended in dilute ammonia solution under vigorous stirring, dissolved with stoichiometric tungstic acid (H2WO4), and then the suspension was deposited on the glass substrate, dried in the air and Fire at 450°C for 4 hours. Repeat the same deposition procedure 3 times to obtain a thick layer with a deposition specific mass of about 0.2 mg cm-2 (±0.05 mg cm-2). Higher than this value indicates that the photocatalytic degradation rate of SA is TiO2-P25. stable.

Under vigorous stirring, dissolve 0.05 mol TiCl4 in 100 ml absolute ethanol, and then dilute with 150 ml water. In this step, ammonium paratungstate powder is introduced according to the selected molar ratio. After that, the ammonia solution was dropped into the TiCl4/ethanol/water/APT solution, and the titanic acid gel precipitated. Rinse the gel and separate by centrifugation until Cl− ions cannot be detected. Then H 2 O 2 solution (30% by weight) was added dropwise to the gel under vigorous stirring until a yellow viscous solution was obtained, which was suitable for spin coating deposition.

Use the spin coating method to deposit only once, for the second and third processes. All catalyst deposits were dried and burned in the air at 450°C for 4 hours, and the annealing temperature in the same range (400-500°C) was used to prepare the coupled WO3/TiO2 catalyst.

In summary, under UV irradiation, higher photocatalytic activity, and better response to the introduction of WO3 were also observed. The inhibition of photocatalysis was also observed under visible light for some WO3 loadings for coupled catalysts prepared by the procedure 2 and a great enhancement was observed at the 0.5 wt % of WO3 under UV light. The coverage rate on the glass is improved. Under 4wt.% WO3, the band gap energy is reduced to 2.3 eV, and the corresponding photocatalytic activity is significantly enhanced under visible light.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com