Pt/WO3 Films for NO2 Gas Sensing

- Details

- Category: Tungsten Information

- Published on Monday, 20 September 2021 00:23

Combustion equipment and automobiles are the major sources of NOx gas including nitrogen dioxide (NO2). These gases have negative effects on the human health and can also cause acid rain. Therefore, effective adsorption materials should be used to sense and detect these gases in the atmosphere.

Tungsten trioxide (WO3) has received considerable attention as a promising sensing material due to its high sensitivity and stability, specifically towards NO2 gas. Meanwhile, doping the WO3 with platinum (Pt) is a promising route to enhance its sensing performance.Thus, Pt/WO3 films for NO2 gas sensing have been prepared by depositing Pt on nanosized WO3 films to improve sensing properties of the films further. The preparation and characterization of Pt/WO3 films is as below:

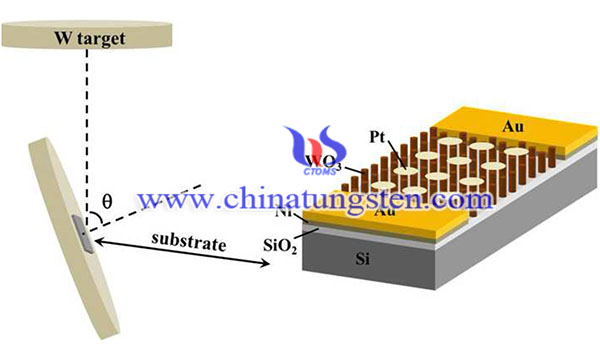

In order to measure the NO2 sensing characteristics of the film, two Ni/Au electrodes were prefabricated on the SiO2/Si substrate. Before depositing the film, these two electrodes are protected by a hard mask. Figure 1 shows the layout of the GLAD used in this work. The glancing angle is 85° (θ = 85°). The 99.99% purity tungsten (W) target is 2 inches in diameter. The distance from the substrate to the target center is 55 mm. Direct current (DC) power supply is used for thin film deposition. In a mixed argon/oxygen (Ar/O2) atmosphere, WO3 film is deposited on the substrate. The Ar/O2 ratio, DC power, sputtering pressure and deposition time are shown in Table 1. In order to further improve the sensing performance of the WO3 film, a layer of Pt nanoparticles was deposited on the surface of the WO3. The Pt target was 2 inches and 99.99% pure. The sputtering pressure is 1.5 Pa. The DC power is fixed at 60 W. After preliminary optimization, Pt is deposited for 10 seconds. Finally, the Pt/WO3 film (labeled g-Pt/WO3) prepared by GLAD was annealed at 450°C for 4 hours. Pure WO3 films were also prepared by planar deposition (α = 0°, marked as p-WO3) and glancing angle deposition (α = 85°, marked as g-WO3) as reference.

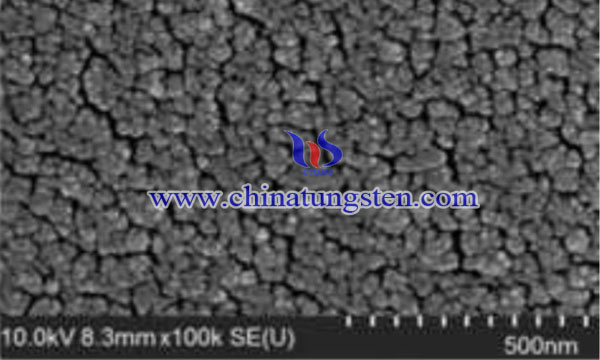

In conclusion, Pt/WO3 films for NO2 gas sensing have been prepared by depositing Pt on nanosized WO3 films to improve sensing properties of the films further. Compared with p-WO3 film, g-WO3 film has greater porosity and larger surface area, which is more responsive to NO2. The deposited Pt forms isolated Pt clusters, which further enhances the gas response. The g-Pt/WO3 film shows the highest sensitivity to NO2 at 150 °C, and can detect NO2 as low as 80 ppb with a response of 1.23. At the same time, g-Pt/WO3 film also shows high selectivity and good stability to NO2. The excellent NO2 sensing properties of g-Pt/WO3 depend on the large specific surface area of nanorod WO3, the catalytic effect of Pt and the Schottky barrier at the interface. Therefore, the Pt/WO3 nanostructures prepared by GLAD have broad application prospects in NO2 MEMS sensors.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com