Tungsten Alloy Military Ring

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 09:49

Tungsten alloy military ring is great to know that someone back home is waiting for you–and hey, the money is a little better as well. Tungsten alloy military ring will hold up to the everyday wear and tear that soldiers put their body’s through. Hauling gear, weapons, and ammo around can be abrasive on most jewelry–but our line of Tungsten Wedding Rings is made to hold up to just such abuse. Oh and BTW, these rings are very good looking – they make great pieces of everyday jewelry as well as wedding rings, promise rings, engagement rings, and even as purity rings. Tungsten alloy is one of the hardest materials on earth, so you don’t have to worry about bending or scratching like you would on a normal precious metal ring.

Tungsten alloy military ring is the most wear resistant rings on the planet, no more bent or scratched rings like gold and platinum–these rings will last a lifetime. Tungsten alloy military ring has a permanent polish to them, and do not need to be cleaned with any special jewelry cleaners.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Ring

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 09:34

Nowadays, tungsten alloy is increasingly used in some field relevant to gold or platinum substitution, such as: tungsten jewelry, e.g. tungsten rings, gold plated tungsten bands, gold plated tungsten rings, ear ring, necklace, wrist chain, etc.Since tungsten alloy bearsa special property of longevity and high durability, when it is utilized to make tungsten alloy rings, it always implicates the love between lovers or couple could be everlasting.

Tungsten rings are a great modern choice for anyone who values high quality jewelry that will last a lifetime. This is because they have fantastic physical properties and a great aesthetic all in one nearly indestructible pattern. Tungsten ring is 7 times harder than stainless steel ring and 4 times harder than titanium rings, tungsten alloy rings' hardness can match the diamond , it is hard , stunning , adamantine luster and noble.

As well tungsten alloy rings have the high corrosion resistance . By synthetic perspiration testing , it is totally not corrosive, not fade and not change in color, not allergic, not rust.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Military Sphere

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 09:24

Tungsten alloy sphere is in small volume with high density, which means it could be used in some fields need the little but heavy parts, such as counterweights for military defense, projectiles in the missile weapons, armor piercing ammunition, hunting equipment, counterweights for hunting gun, prefabricated fragments, the missile weapons, armor piercing ammunitio, tungsten alloy bullet.

Tungsten alloy sphere can be also used as bullets or pellets in many military filed. These are the pellets from inside a shotgun shell. Lead shot and bullets have been banned in many areas because they poison the environment. The main substitute materials are steel, bismuth and tungsten. The main advantages of tungsten alloy ball which made as pellet are that it's very dense, and very hard. The density allows the pellets to fly long distances without slowing down, while the hardness allows the pellets to keep their shape while being accelerated by the powder charge, which increases the muzzle velocity.

As well tungsten alloy sphere is widely used in hand grenade, armor piercing projectile, prefabricated fragments.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Counterweight

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 09:10

Tungsten alloy counterweight is used for the design of aircraft control surfaces, the aircraft's rotor blades,guidance platforms and vibration.

To vibration, for example, tungsten alloy counterweight is used in the rotating system, such as automobile tires, to reduce vibration. Vibration measurements do not need any weight can determine the bearing point. Tungsten alloy counterweight on the opposite bearing point balances the load, reducing or eliminating the vibration.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

WHA Weights

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 08:58

WHA (tungsten heavy alloy) weights for fixed and rotary wing aircraft have been used for many years. WHA weights, unlike lead which creeps under its own weight at room temperature, can be securely fastened to aerostructures. In contrast to DU weights, WHA weights are free from SCC concerns, special licensing requirements, environmental issues, and the negative public response to having many pounds of radioactive material routinely flying overhead.

WHA weights are typically machined from near net shape blanks to precise tolerances and provided with a protective coating to the customer's specification. This is an application where a coating is highly recommended to resist corrosion from temperature and moisture cycling, de-icing fluids, aggressive aircraft cleaning fluids, and galvanic contact with fasteners and the airframe. Class 1 or 2 WHAs are most commonly used.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Cylinder

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 July 2013 08:52

The density of tungsten cylinder is about 1.8 times than lead, which means that the tungsten is the size of lead about half of the same quality.

Pine car is so small, it is important to place the exact location, you need to determine its weight. Single tungsten cylinder at the top (0.5 oz) weight close to the bottom of the three zinc cyclinders (0.75 ounces) is the same as when your car is designed to give you more space, because you can be placed in a small area of high weight, more precise with weights.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Housing Shielding

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 13:39

With rapid development of medical science, more and more radiation instruments are used in our lives. Medical instruments and nuclear power stations have become widespread and are now affecting all our lives. It is essential that people paid more attention to radiation and even more important for the institutions to protect public from the radiation exposure and to make sure to protect every radiation source of X-ray radiation, gamma radiation (energetic electromagnetic radiation), radiation of alpha particles (helium atoms) beta particles (electrons) and cosmic radiation, etc.

In order to protect patients and personnel from harmful effects of ionizing radiation, such as breast cancer, skin cancer, etc an excellent radiation-absorbing medium is badly needed. Tungsten alloy housing shielding is the material to be used for radiation shielding.

Tungsten alloy is ideal for tungsten alloy housing shielding against X-rays and gamma radiation. The very high density of tungsten alloy housing shielding (more than 60% denser than lead) allows a reduction in the physical size of shielding components, without compromising their rigidity or the effectiveness of the tungsten alloy radiation shielding characteristics.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Heater Filament

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:45

Tungsten heater filament is made of tungsten wire, featuring high melting point and high corrosion resistance, mainly application in vacuum metalized applicant, such as aluminizing scope, aluminum spraying, chrome scope, mirror making, ceramic coating, plastics and heater element for decoration articles.

Tungsten heater filament can be stranded into single or multi wires according to the samples or drawings of customers. Pure wire and doped wire are both available. Diameter of tungsten wire: 0.2-1.2mm.

Tungsten heater filament, single or multiple strand tungsten, molybdenum, or tantalum wire. Stranded wire can incorporate a core of aluminum for wetting purposes.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

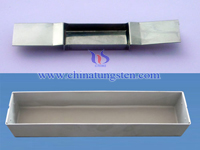

Tungsten Boats

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:40

As a special and effective boat vessel, tungsten boats are widely used in metallizing, electron-beam spraying as well as the heat process with sintering and annealing in vacuum coating industries.

Tungsten boats sources are used for the vacuum evaporation of materials that are in granular or pellet form. They can also be used to evaporate small lengths of wire or to evaporate materials which would not properly "wet" the surface of an evaporation filament. These boats are ideal for use in small evaporation systems, such as bell jars, for experimental and prototype work.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:31

Tungsten contacts are used in high voltage applications, usually where highly repetitive switching is required. Tungsten has a melting temperature of 3,380℃ which gives it excellent arc-erosion resistance.

Tungsten contacts may develop troublesome oxide films, especially when used as the anode contact in some DC applications. Therefore, tungsten contacts are often used as the cathode contact, and a palladium alloy used as the anode contact. Such a combination also minimizes contact interface resistance and material transfer.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com