Effect of Coating Preparation Method on Oxidation Behavior of W-Based Materials

- Details

- Category: Tungsten's News

- Published on Tuesday, 02 May 2023 17:17

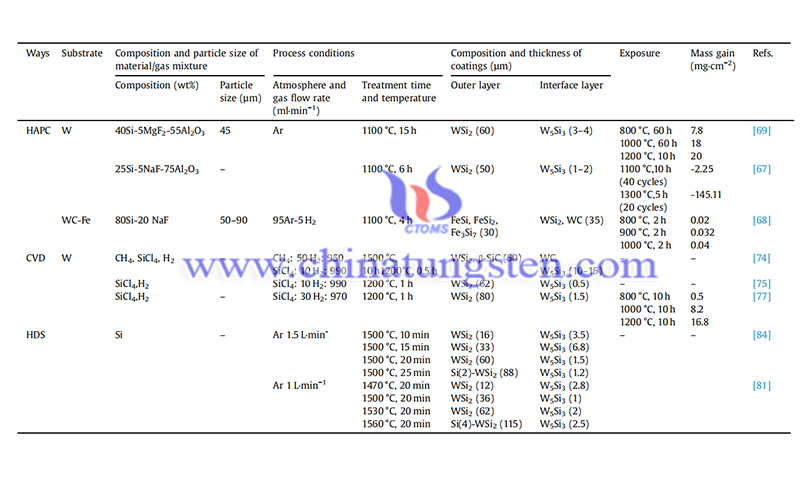

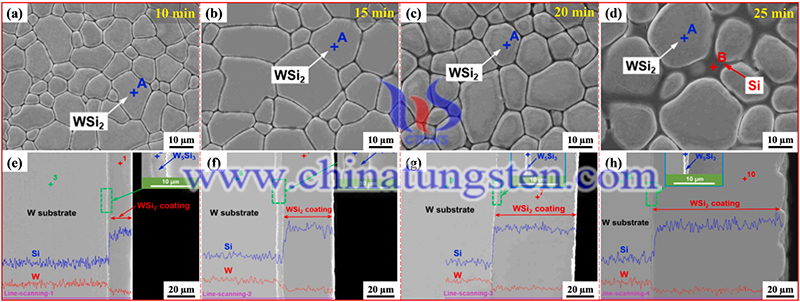

Researchers summarize the effects of different coating preparation methods on the coating composition and oxidation behavior of W-based materials. It can be seen that the silicide coating consists mainly of a thick WSi2 layer and a thin W5Si3 layer. The HAPC coating requires a longer time due to the relatively low diffusion temperature. After 4~15 hours of treatment at 1100 °C, the thickness of the coating is only 30~60 µm. However, using CVD technology, the thickness of the coating can reach 50~80 microns after 0.5~1 hour of deposition at 1200°C. In contrast, the HDS technique is very efficient for coating preparation. By depositing at 1500°C for 0.25~0.42 h, coatings with thicknesses of 36~88 µm can be obtained.

However, studies on the oxidation resistance of that kind of coating on W-based materials have not been reported, which deserves further study by interested scholars. Each coating has a similar structure and can be divided into three different temperature zones according to its oxidation pattern. When the temperature is below 1000°C, the oxide layer consists of layered WO3 and amorphous SiO2, and oxygen is transported to the interior along the cracks and holes on the coating surface. With the gradual volatilization of WO3 and the thickening of the oxide layer, the oxidation rate of the coating gradually decreases. When the temperature is between 1100°C and 1200°C, the porosity of the coating increases rapidly due to the decomposition of the WSi2 phase into W5Si3.

The diffusion of oxygen to the inside of the coating is accelerated, and a large amount of WO3 is generated at the cracks inside the coating, which leads to volume expansion and further accelerates the oxidation behavior. When the temperature is above 1300°C, the WO3 produced during oxidation volatilizes in large quantities due to high vapor pressure, and the viscosity of SiO2 gradually decreases. A continuous and stable quartzite layer is formed on the surface of the oxide layer. This means that the self-healing ability of the coating is significantly enhanced. Optimizing the structure of the coating, appropriately increasing the thickness of the interfacial layer, and reducing the defects caused by the CTE mismatch between WSi2 and W substrates are of great significance to extend the oxidation life of the coating.

Reference: Fu T, Cui K, Zhang Y, et al. Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review[J]. Journal of Alloys and Compounds, 2021, 884: 161057.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com