High Precision Turning Reduces Costs of Tungsten Carbide Tool

- Details

- Category: Tungsten's News

- Published on Saturday, 14 May 2022 22:35

High precision turning reduces the cost of the tungsten carbide tool and minimizes setup time. Tungsten carbide tools are often used in the tooling industry as well as in punching, drawing, and extrusion applications. These dies are very wear-resistant and often have complex contours with the highest requirements for shape and surface finish. Because these workpieces are difficult to machine, they have traditionally been formed by grinding with diamond grinding wheels.

However, as manufacturers face the challenge of reducing costs, improving quality, and minimizing setup times, high precision hard turning is being considered. High precision turning is a very flexible process that is easy to set up and convert.

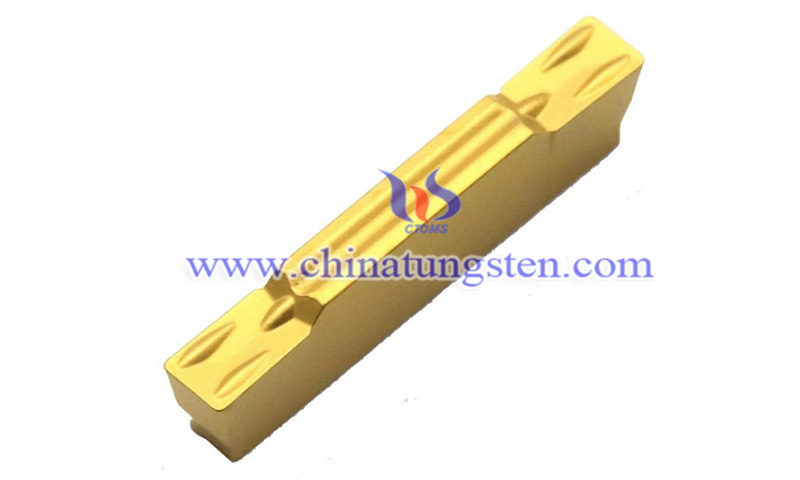

By combining a dynamically rigid and precise turning machine with a diamond indexable insert tool, a flexible manufacturing process for carbide tool finishing can be achieved.

Tungsten carbide can reach hardness values of 80 HRC. hardened steel, for example, has a hardness between 58 and 65 HRC. Turning this material on conventional lathes causes vibrations, as these machines usually have minimal machine damping characteristics.

The high cutting forces required to pull the material away from the workpiece are higher in carbide than in hardened steel. These higher cutting forces exert significant back thrust pressure on the guideways and spindle bearings. Conventional lathes cannot always handle these forces, and premature wear of the guideways can occur even when cutting hardened steel, let alone carbide. This leads to a reduction in the ability of the part to maintain its size, shape accuracy, and surface finish, and increases tool wear.

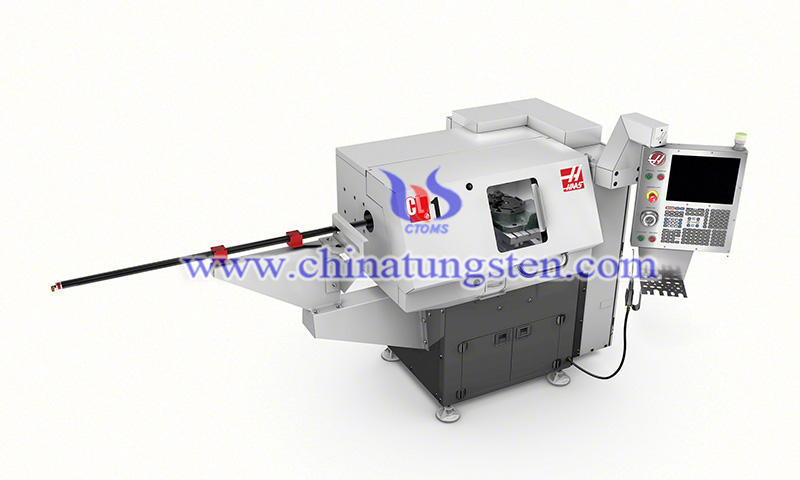

Hembrug Machine Tools of Haarlem, Netherlands, part of the Spanish machine group Danobat, specializes in high precision hard turning machines. It also has extensive process experience in turning tungsten carbide workpieces that require very tight tolerances with sub-micron precision.

The company broke away from the conventional method of lathe construction and developed hydrostatic slides and spindle bearings. This in-house technology is used in the slide and spindle bearings of the company's Mikroturn high precision turning. This technology provides the damping characteristics and creates the speed-independent dynamic stiffness necessary to minimize tool tip vibration. These characteristics are essential for good surface finish and long tungsten carbide tool life

Carbide cutting tools, also known as cemented carbide cutting tools or tungsten carbide cutting tools are the leading products of CNC machining tools. In some countries, more than 90% of turning tools and 55% of milling tools are made of cemented carbide, and this trend is increasing.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com