Novel Tech Makes Eco-Mining A reality for Rare Earths

- Details

- Category: Tungsten's News

- Published on Friday, 08 April 2022 22:20

New research from the University of South Australia may change the way rare earths and other important metals are recovered, making eco-mining possible and reducing environmental impact.

Dr Richmond Asamoah from the Institute for Future Industries at the University of South Australia is developing new methods for the safe extraction of key minerals from downstream ore processing, tailings reprocessing, and wastewater treatment. He is also developing mechanisms for the safe recycling of waste products such as used batteries and magnets.

Dr. Asamoah said, "Rare earth minerals and battery metals are critical to the economic well-being of the world's major and emerging economies, yet the supply of these critical metals is unreliable due to geological scarcity, geopolitical issues, and trade policies."

Mining wastes are becoming an increasingly valuable source of metals and energy, but there is also a significant depletion of these critical metals due to the lack of productive and economically viable extraction technologies. The process of extracting these critical metals is environmentally destructive, and conventional mining methods can produce large amounts of toxic and radioactive materials.

This research will identify new technologies that are capable of both extracting minerals from existing industrial waste and mineral tailings, and recovering and obtaining minerals and metals from spent batteries and magnets. As a result, it should be possible to significantly reduce the amount of waste and hazardous substances that may leach into the environment.

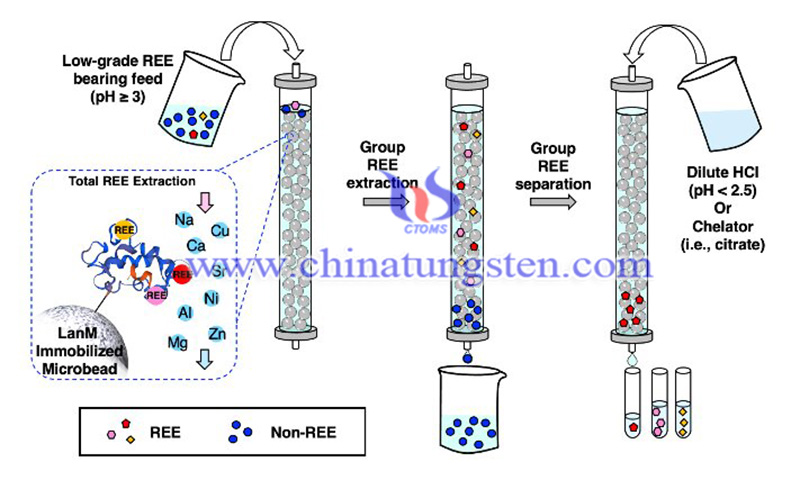

The project will test two metal recovery processes, in-pulp resins and wetted hybrid resins to extract target metals from low-grade ores, fine minerals, and wastes, such as tailings. These processes can also be used to remove hazardous substances from water and soil to minimize environmental impact.

The research is being conducted with funding from the Australia-India Strategic Research Fund, and Dr. Asamoah said, "This research will be of great benefit to both countries. We're not just talking about environmental benefits, but also economic and sustainable technologies that both countries can use to extract rare earths and battery minerals from current mining operations."

Rare earth elements contribute nearly $200 billion to the Indian economy, yet despite having the world's fifth-largest reserves of the key metal, they mostly import rare earth requirements from China.

The project hopes to enable Australia to export rare earth minerals to India as an alternative to China and to give India the ability to establish ecological technologies to extract minerals and metals within its borders.

Importantly, this new technology makes eco-mining of rare earths possible and will build the capacity to process key minerals in Australia and India and create many new eco-efficiency opportunities for economic growth, jobs, and investment.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com