American Resources Receives Approval for Rare Earth Purification and Isolation Facility

- Details

- Category: Tungsten's News

- Published on Sunday, 05 December 2021 19:16

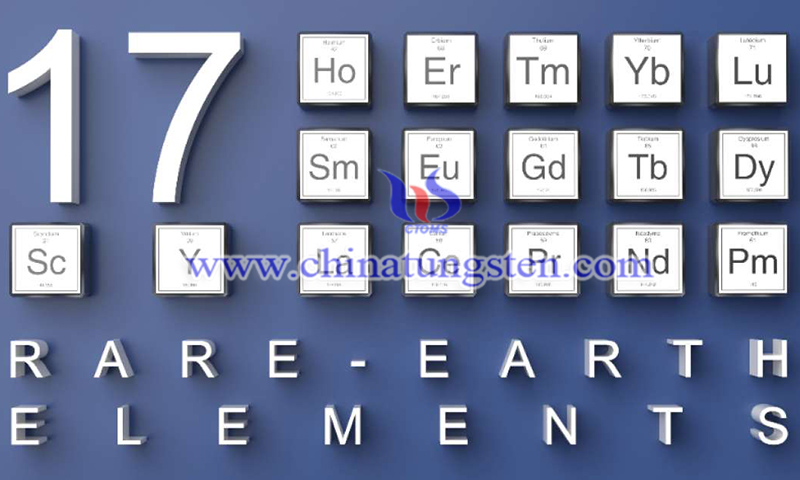

American Resources Corporation recently announced another milestone for the company with the final permitting of its first rare earth and key element purification and isolation facility currently under construction in Noblesville, Indiana.

This facility will be the company's first of its kind as it continues to execute on its innovative goal to separate and purify key and rare earth elements (REEs) using the most economically viable and environmentally safe methods developed to date, helping to create a competitive domestic supply chain.

Just as it has been successful in recovering REE magnet metals and battery metals using its patented chromatography technology and processes, American Rare Earths will be able to commercially process these high value raw materials to over 99% purity for re-use in the manufacture of new products for the electrification market.

Mark Jensen, Chief Executive Officer of American Resources, Inc. Mark Jensen commented, "As we continue to execute on our goal of leading the U.S. in the commercial processing of critical and REEs and bringing truly impactful solutions to our domestic supply chain, it also gives us the ability to work with local representatives that will help us achieve our overall goals."

"In addition, our ability to effectively navigate the permitting process underscores the environmentally safe nature of our chromatography processes and facilities and allows us to rapidly expand our operations with more flexibility and lower costs than other existing approaches."

This first purification and isolation facility is initially designed to have two production trains utilizing a process and control center. The first train will focus on recycling rare earth permanent magnets to recover, separate, and purify the inherent REEs neodymium (Nd), praseodymium (Pr), and dysprosium (Dy) and to establish a viable recycling life cycle and economy for these materials, which historically have often been landfilled.

The second line will focus on battery metals and refining black mass to recover, separate, and purify its inherent cobalt (Co), nickel (Ni), lithium (Li), and manganese (Mn) from scrap, such as end-of-life lithium-ion batteries from electric vehicles that the Company receives through its own efforts and those of third-party partners. This initial facility is under construction and is being financed from capital currently on the balance sheet and does not require the raising of additional external capital.

The company is also planning and developing its larger facility, also located in Noblesville, Indiana, just three miles from the first facility, having procured a seven-plus acre site in August 2021. Given the current supply chain constraints resulting in extended lead times for construction materials, the company turned to leasing an existing structure to build its first two commercial chromatography production trains. The design plan for the larger facility includes up to 12 commercial production trains for a variety of key and rare earth feedstocks.

American Resources continues to focus on running efficient, streamlined operations to be the most sustainable supplier of new-age raw materials to the infrastructure and electrification markets, while also helping the world achieve its goal of carbon neutrality. By operating at low or no cost and with one of the largest and most innovative growth pipelines in the industry, American Resources strives to maximize value for its investors, positioning its large asset base to best serve the new age economy while being able to expand its operations to meet the growth of the markets it serves.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com