Domestic Rare Earth SCR Catalysts for Diesel Vehicles

- Details

- Category: Tungsten's News

- Published on Tuesday, 20 April 2021 19:50

Parts of the research and development results of the China VI standard rare earth SCR catalysts for diesel vehicles of the Rare Earth Catalytic Materials Research Group of Baotou Research Institute of Rare Earth have passed the bench test certification of the National Automobile Quality Supervision and Inspection Center, Dongfang Commercial Vehicle and other third parties.

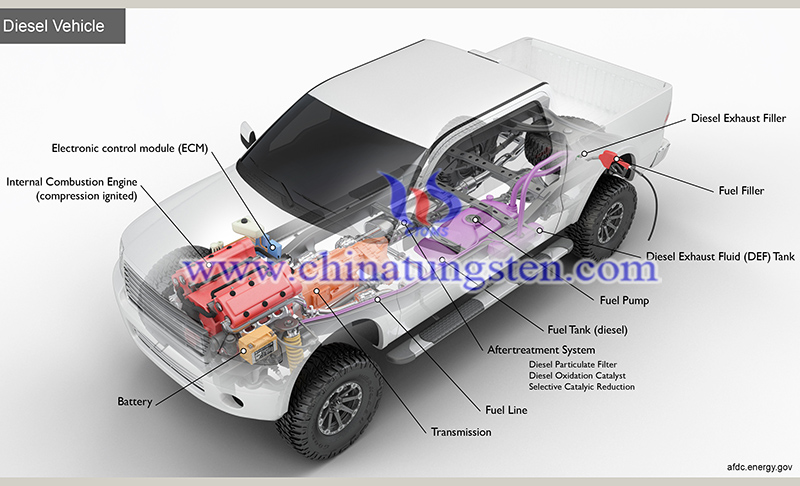

"The China VI standard is currently one of the most stringent emission standards in the world, and the SCR after-treatment system is a key part of the diesel exhaust aftertreatment system. Its function is to reduce and transform the NOx components in the exhaust gas,” said Zhaoqiang Li, the leader of the research group.

For the treatment of nitrogen oxides emitted by diesel vehicles, selective catalytic reduction (SCR) technology is mainly used in the market, and the core is the catalyst. "Commercial denitration catalysts mainly include vanadium, tungsten, titanium, and molecular sieves, and the related technologies and intellectual property rights of the above two catalysts are mainly monopolized by large foreign companies such as BASF and Johnson Matthey.

Rong Wang, director of the Institute of Hydrometallurgy of Baotou Research Institute of Rare Earth, said that vanadium tungsten titanium catalysts are mainly used in the China V standard stage and have low production costs, but its main active ingredient, vanadium oxide, is a highly toxic substance. While molecular sieve catalysts are mainly used in the sixth stage in domestic, although they have good low-temperature activity and high-temperature stability, their cost is relatively high.

Through several years of program improvement and experimental testing, Li's research team has successfully developed a catalyst powder with excellent low-temperature activity and high-temperature stability. Through the adjustment of the formulation and preparation process, the catalyst can meet the requirements of the various standard. On the basis of SCR performance, improve its resistance to hydrothermal aging and anti-toxicity, breaking the monopoly of foreign companies.

The research group added a sufficient amount of rare earth components to the catalyst. "Compared with the commonly used vanadium-based catalysts and molecular sieve catalysts, it owns good conversion efficiency and durability." Zhaoqiang Li introduced that the exhaust gas after-treatment system could be used in the rare earth SCR Under the action of the catalyst, ammonia is used as a reducing agent to react with nitrogen oxides emitted by diesel vehicles, reducing them to harmless nitrogen and water for discharge, achieving the goal of purifying diesel vehicle exhaust.

"As if every car equipped with rare earth SCR catalyst to become a filter. After treatment, the exhaust gas can meet the emission standards." Zhaoqiang Lix said. Through calculations, using the rare earth SCR catalysts with independent intellectual property rights can save 10% to 20% in cost compared to paying for foreign catalyst patents.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com