US Purdue University Grows Greener Process for Rare Earths

- Details

- Category: Tungsten's News

- Published on Friday, 29 May 2020 17:47

Purdue University has developed a more environmentally and economically feasible rare earths mining technology. The new technology has been patented and is about to rewrite the industrial ecology to help the US create a more stable local supply.

Used in computers, cell phones, DVDs, rechargeable batteries, catalytic converters, magnets, wind turbines, and fluorescent lights, and for defense in laser range-finders, guidance systems, and precision-guided weapons, these metals are difficult to mine because it is unusual to find them in concentrations high enough for economical extraction.

Besides, the current acid-based rare earth metal separation and purification technology of rare earth metals are detrimental to the environment, and most companies around the world cannot enter the market.

China is a major global producer of rare earth production. 36% of the global reserves of 17 rare earth metals are in the hands of China. At present, China no longer sells rare earth at a price lower than the production cost like in the 1980s and 1990s, providing other countries an opportunity to become rare earth producers.

But when China lowered its export quota for rare earth metals in 2010, the cost of rare earth magnets for a wind turbine soared from $ 80,000 to $ 500,000. Eighteen months later, China eased export restrictions and prices returned to levels below 2010. China is also the dominant consumer of rare earths for manufacturing electronics products for domestic and export markets. Today Japan and the US are the second and third largest consumers of rare earth materials.

Almost 60% of rare earth metals are used to produce magnets. Rare earth magnets with permanent magnets are almost ubiquitous in everyday life, whether it is electronic products, aircraft, hybrid vehicles or fans. Nien-Hwa Linda Wang, a professor of chemistry at Purdue University who developed a new technology, said: "We currently have one dominant foreign source for these metals and if the supply were to be limited for any reason, it would be devastating to people's lives," Wang said. "It's not that the resource isn't available in the U.S., but that we need a better, cleaner way to process these rare earth metals."

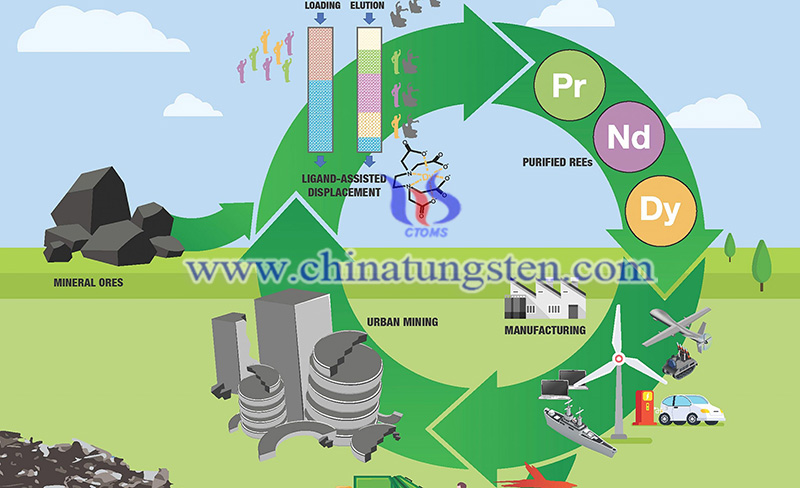

The new patented extraction and purification technology use ligand-assisted chromatography, which has been proven to safely and effectively separate rare earth metals from coal ash, recovered magnets, and raw ores, with little adverse impact on the environment.

The production of rare-earth metals has a global market of 4 billion US dollars per year. With the development of new electronic products, aircraft, warships, electric vehicles, magnets, and other important products that require rare earth metals, this market continues to grow. The value of products relying on rare earths is more than 4 trillion US dollars each year.

Wang explained: "Conventional methods for producing high-purity rare earth elements employ two-phase liquid-liquid extraction methods, which require thousands of mixer-settler units in series or parallel and generate large amounts of toxic waste. We use a two-zone ligand-assisted displacement chromatography system with a new zone-splitting method that is producing high-purity (99%) metals with high yields (99%).

Wang's ligand-assisted method has the opportunity to recover rare earth metals from waste magnets and ores in an efficient and environmentally friendly way and helps make rare earth processing a cyclical process.

Joe Pekny, professor of chemical engineering at Purdue University said that Wang's innovation enables the United States to reenter the rare earth metals market in an earth-friendly, safe and sustainable way. “What’s exciting is that the U.S. has the rare earth metals to meet the growing demands of the U.S. market and other markets around the globe and reduces our dependence on foreign sources.”

This research of Purdue University was partially funded by the US Department of Defense (DoD). The U.S. Department of Defense is supporting the U.S. rare earths supply chain with a new contract to a once defunct uranium mine in the California desert that is now the only rare earth mining and processing site in North America.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com