Tungsten Inert Gas Welding Combines with Robot Shines CIIF

- Details

- Category: Tungsten's News

- Published on Monday, 23 September 2019 22:45

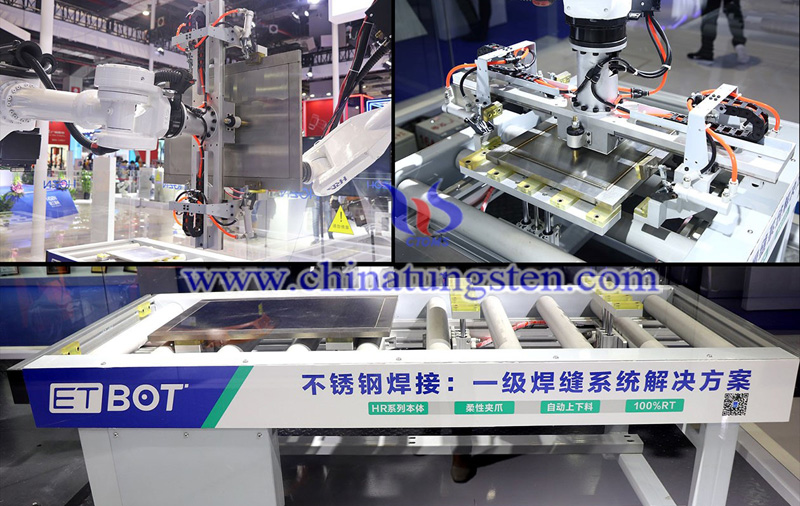

Tungsten Inert Gas (TIG) welding solution combines with stainless-steel robot welding shown in the 21st China International Industry Fair (CIIF) which held in the National Exhibition Center (Shanghai). And with the first-level weld system solution and several technological innovations, it becomes a hot product.

As we all know, stainless steel is widely used in the industrial field, but due to its high welding process and product quality requirements, it is still difficult to achieve automated welding. Stainless steel has the characteristics of a high expansion coefficient and low thermal conductivity. The traditional arc welding method not only has low welding efficiency but also is prone to large deformation during the process, resulting in defects and dimensional deviations on the weld surface, which is difficult to meet, for example, pressure vessels.

Application of robot welding + Tungsten Inert Gas welding process shown in the CIIF has improved product quality. Based on characteristics of stainless steel, combined with special requirements of the industry, the research, and development of high-end configuration with advanced technology stainless steel welding system greatly improving the quality and efficiency of welding.

This system consists of the HRG12KG six-axis robot, HRG50KG six-axis robot, Funis argon arc welding machine, Binzell argon arc filler welding gun, laser tracking system, flexible handling jaws, automatic flow water cutting platform, using emerging welding technology - TIG (filled wire / self-melting).

When TIG welding is used for stainless steel, it can effectively eliminate the damage of welding metal by oxygen, nitrogen, hydrogen and other gases due to the good protection effect. The reliability is high and the welding process is stable, which is conducive to achieving high-quality welding and obtaining excellent weld seam. At the same time, the heat-affected zone of the weld is small, the weldment deformation is small and the corrosion resistance is good, and the operation is easy, and the laser tracking system is used to effectively perform weld seam identification, tracking, and automatic detection.

Using non-destructive testing on the finished product after welding, there are no flaws found in the weld, such as cracks, incomplete penetration, pores, and slag inclusions, etc. The weld is beautiful, smooth, and uniform, achieving 100% RT flaw detection requirements.

The newly developed self-designed automatic water-flowing platform can meet automatic feeding, clamping, and blanking of a variety of workpieces, instead of manual operation, it can control beats well, avoiding impact on production beats due to human factors, greatly improving production efficiency.

Tungsten Inert Gas welding solution combines with robot welding shines CIIF, and it also owns great meaning to industry wedding development. At present, there are successful cases in the automotive, special vehicles, pharmaceutical equipment, engineering machinery, pressure vessels, and steel structures, etc. For example: from the simple and practical pressure vessel and environmental parts welding system to process difficulty ultra-high boss frame and port machine welding system.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com