Ammonium Metatungstate Preparing Nano Tungsten Oxide Aqueous Solution

- Details

- Category: Ammonium Metatungstate

- Published on Monday, 05 December 2016 15:59

- Hits: 1599

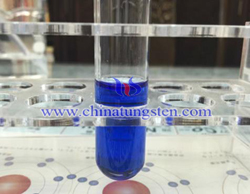

Nano tungsten oxide can not soluble in water itself, the so called nano tungsten oxide aqueous solution is the dispersion which nano tungsten oxide particles are uniformly distributed in water, to play the roles of oxidization and reunion of tungsten oxide. Tungsten oxide is the typical transition metal oxides, while the nano tungsten oxide is a new type of functional material, and because of its excellent discoloration performance, it can be widely used in many fields, such as intelligent window, large area flat panel display, gas sensor, dye-sensitized solar cell, automatic mirror, energy storage.

Nano tungsten oxide can not soluble in water itself, the so called nano tungsten oxide aqueous solution is the dispersion which nano tungsten oxide particles are uniformly distributed in water, to play the roles of oxidization and reunion of tungsten oxide. Tungsten oxide is the typical transition metal oxides, while the nano tungsten oxide is a new type of functional material, and because of its excellent discoloration performance, it can be widely used in many fields, such as intelligent window, large area flat panel display, gas sensor, dye-sensitized solar cell, automatic mirror, energy storage.

Ammonium metatungstate (AMT) is the important intermediate compound of tungsten metallurgy, and being the important raw material for manufacturing tungsten oxide, tungsten and tungsten carbide powder and other tungsten products. An invention has proposed one method to prepare nano tungsten oxide aqueous solution from the raw material of ammonium metatungstate and sodium borohydride, with the steps like bellows:

1. Weight the appropriate amount of ammonium metatungstate and sodium borohydride according to the mass ratio of 1~10:1;

2. Add the AMT powder into deionized water to dissolve with stirring and get the ammonium metatungstate aqueous solution with the concentration of 5~50%;

3. Add the weighted sodium borohydride solid into the AMT solution and stir to mix them uniformly, stay to react for 10~60 minutes under the room temperature to 95°C to get the blue nano tungsten oxide aqueous solution with 0.1〜10nm uniform particle size. since the ammonium metatungstate will react with sodium borohydride to generate blue nano WO2.9, and it will release heat, a large number of hydrogen gas and ammonia gas during the reaction process, which will remove purity of ammonium ion.

Nano tungsten oxide aqueous solution prepared by this method has the advantages of good stability, small particle size of nano tungsten oxide and others, thus to have wide application in intelligent window, gas sensor and solar energy cell and other fields.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Nanoscale Zirconium Tungstate Hollow Sphere

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 30 November 2016 17:28

- Hits: 1707

The cubic zirconium tungstate is one of the hotspots in the research of negative thermal expansion materials, with its widest range of negative expansion effect, high negative expansion coefficient and isotropy and other advantages, it can be combined with positive expansion into the specific materials with zero or low expansion, and thus to be used in the some devices which is used under extreme temperature conditions field of aerospace. The preparation methods of zirconium tungstate are solid phase sintering, sol-gel, combustion, chemical coprecipitation and microwave method ect., however, the zirconium tungstate particles or whiskers prepared by these methods are irregular, and can not be used in some specific fields, such as aerospace.

There is an invention disclosed a method for preparing nanoscale zirconium tungstate hollow sphere by hydrothermal synthesis method from the raw materials of ammonium metatungstate (AMT) and zirconium oxychloride, with the steps as following:

1. Respectively weight the right amount of ammonium metatungstate and zirconium oxychloride according to the stoichiometric ratio of zirconium tungstate (ZrW2O8), respectively, and prepare zirconium oxychloride aqueous solution and ammonium metatungstate aqueous solution respectively;

2. Add zirconium oxychloride aqueous solution into ammonium metatungstate aqueous solution under the condition of stirring, then preheat the mixture at the temperature of 60~70℃ with stirring continuous;

3. Add hydrochloric acid solution with continuously stirring, and then heat the solution to 80~100℃, then we get the zirconium tungstate precursor suspension after keeping the temperature for a proper time;

4. The zirconium tungstate precursor suspension is carried out a hydrothermal reaction at a temperature of 170~190℃, followed by cooling, collecting the precipitate and washing to remove chloride ions (Cl- ), drying, calcining at 800~1000℃, and finally to obtain nanoscale zirconium tungstate hollow sphere.

In this method of preparing zirconium tungstate by using AMT as raw material, due to the hydrothermal synthesis method can truly realize synthesizing zirconium tungstate powder at a low temperature, cut down the synthesis time of the precursor and control the direction of crystal growth; thus, the prepared nanoscale zirconium tungstate hollow sphere has the benefits of uniform particle size, good negative expansion performance and low density ect., and to have great potential for applying in aerospace field.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.29th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 29 November 2016 14:42

- Hits: 1685

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.29th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Arsenic Doped Ammonium Metatungstate Preparing Nano Tungsten Powder

- Details

- Category: Ammonium Metatungstate

- Published on Monday, 28 November 2016 16:28

- Hits: 1791

Arsenic doped ammonium metatungstate (AMT) is generated by adding ammonium metatungstate into the nitric acid solution of elemental arsenic and stirring, drying and grinding, the excellent raw material for preparing nano tungsten powder. Nano tungsten powder is the tungsten powder which the particle size is fine to nanoscale, at present, the traditional method for manufacturing nano tungsten powder is tungsten oxide reduction method, wherein the reducing agent maybe hydrogen or carbon; with the appearing of nano materials, the manufacture methods of nano tungsten powder are emerging constantly, such as high-energy ball milling, gas evaporation, plasma, self-propagating high-temperature reduction and molten salt electrolysis method.

Arsenic doped ammonium metatungstate (AMT) is generated by adding ammonium metatungstate into the nitric acid solution of elemental arsenic and stirring, drying and grinding, the excellent raw material for preparing nano tungsten powder. Nano tungsten powder is the tungsten powder which the particle size is fine to nanoscale, at present, the traditional method for manufacturing nano tungsten powder is tungsten oxide reduction method, wherein the reducing agent maybe hydrogen or carbon; with the appearing of nano materials, the manufacture methods of nano tungsten powder are emerging constantly, such as high-energy ball milling, gas evaporation, plasma, self-propagating high-temperature reduction and molten salt electrolysis method.

There is a study to take ammonium metatungstate as raw material, and through doping process to get arsenic doped ammonium metatungstate to finally get nano tungsten powder, with the producing process like the following:

1. Preparation of arsenic doped ammonium metatungstate precursor composite powder

Add a certain amount of elemental arsenic into the nitric acid with a certain concentration, then add ammonium metatungstate into the nitric acid solution of elemental arsenic after the As is completely dissolved with the arsenic content being controlled; electric mix the raw materials, then dry them in a oven under 70~90°C for 8~10 hours, and then, grind to get arsenic doped ammonium metatungstate precursor compound powder.

2. Arsenic doped ammonium metatungstate calcination to prepare yellow tungsten trioxide powder

Put the prepared arsenic doped ammonium metatungstate precursor compound powder in a box type resistance furnace at the temperature of 580~620°C to carry out calcination in air atmosphere for 2~3 hours, then we get yellow tungsten trioxide powder.

3. Tungsten trioxide reduction to generate nano tungsten powder

Put the yellow tungsten trioxide powder in a tube furnace to get reduction by inletting hydrogen, under the reduction temperature of 780~820°C with the heating rate of 5°C/min, and the heat preservation time of 3~4 hours, to finally manufacture nano tungsten powder

The nano tungsten powder get by arsenic doped ammonium metatungstate has the advantages of good dispersion, and uniform particle size distribution, thus to effectively promote the development and application of nano-crystal WC-Co alloy.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.25th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 25 November 2016 09:50

- Hits: 1654

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.25th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Violet Tungsten Oxide Whisker

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 24 November 2016 15:27

- Hits: 1739

Ammonium metatungstate (AMT) is an important compound in tungsten metallurgy industry, an important raw material for preparing tungsten oxide, such as tungsten trioxide (YTO, WO3), violet tungsten oxide (VTO, WO2.72 or W18O49). Violet tungsten oxide whisker is the micro-nano-short fibers which are generated by the high purity violet tungsten oxide, with the mechanical strength equal to the strength of adjacent atoms between the intensity. The highly oriented structure of W18O49 whisker has not only making itself of high strength, modulus and elongation, but also of the properties of electrical, optical, magnetism, dielectricity, conductivity and superconductivity.

Ammonium metatungstate (AMT) is an important compound in tungsten metallurgy industry, an important raw material for preparing tungsten oxide, such as tungsten trioxide (YTO, WO3), violet tungsten oxide (VTO, WO2.72 or W18O49). Violet tungsten oxide whisker is the micro-nano-short fibers which are generated by the high purity violet tungsten oxide, with the mechanical strength equal to the strength of adjacent atoms between the intensity. The highly oriented structure of W18O49 whisker has not only making itself of high strength, modulus and elongation, but also of the properties of electrical, optical, magnetism, dielectricity, conductivity and superconductivity.

It is pointed out that a process for producing violet tungsten oxide whiskers by coaxial electrostatic spinning method with ammonium metatungstate as a raw material is as follows:

1. Mix 2ml saturated ammonium metatungstate solution and 12% PVA solution in a certain proportion, to prepare spinning solution;

2. Inject the best electrospinning solution into 10ml syringe, and install it in the syringe pump to carry out a single tube electrospinning experiment. In the spinning process, solvent will volatilize partly in the air and form ammonium metatungstate/PVA composite fiber;

3. Calcine the obtained ammonium metatungstate / PVA composite fiber in the air to remove the solvent and the matrix PVA, and the ammonium metatungstate is decomposed by heating to obtain WO3 one-dimensional nanofibers at the same time;

4. The WO3 one-dimensional nanofibers is transformed to some specific crystal type and appearance by a certain heat treatment process, thereby to get W18O49 whisker.

The results showed that 800 ℃ is the optimum temperature for the formation of violet tungsten oxide whisker, and the W18O49 whisker nanorods are different in length. In addition, from the transmission electron microscopy (TEM), SEM, XRD and SAED patterns, we can observe that W18O49 whiskers are growing independently of each other with the smooth surface, with nano-level diameter and micron-length, large aspect ratio, and the is diameter mainly among 170nm-250nm, the length is mainly between 2-3μm, long diameter ratio mainly among 10-17, thus to be with some unique properties.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparation -- Nitric Acid Neutralization Method

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 22 November 2016 16:15

- Hits: 1697

Ammonium metatungstate (AMT) is an important intermediate compound during the tungsten wet smelting process, white or yellowish crystals, which has the highest solubility in all tungsten compounds (303g/100mL under 20°C in water). There are many preparation methods of ammonium metatungstate, such as thermal decomposition, tungsten acid, electrodialysis, solvent extraction, ion exchange method, while the thermal decomposition method based on the raw material of APT is the main process for manufacturing AMT in industrial currently.

Ammonium metatungstate (AMT) is an important intermediate compound during the tungsten wet smelting process, white or yellowish crystals, which has the highest solubility in all tungsten compounds (303g/100mL under 20°C in water). There are many preparation methods of ammonium metatungstate, such as thermal decomposition, tungsten acid, electrodialysis, solvent extraction, ion exchange method, while the thermal decomposition method based on the raw material of APT is the main process for manufacturing AMT in industrial currently.

Being one class of preparation method, acid neutralization method has been focused and widely used in the industry because of its simple process and equipment. Some studies have followed on the nitric acid neutralization method, taken ammonium paratungstate (APT) as raw material to convert and generate AMT in an environment of nitric acid, which is heating a certain amount of deionized water, and slowly adding APT and dilute nitric acid solution with the ratio of 1:20 with stirring, then controlling the transformation temperature within limits to convert APT to AMT in the liquid phase and generate AMT solution, and finally get ammonium metatungstate crystal after the steps of ageing, preconcentration, concentration, crystallization, solid-liquid separation and drying. Wherein, the reaction equations of APT converts to AMT by nitric acid neutralization method is like:

(NH4)10W12O41.xH20+4HNO3= (NH4)6H2W12O40.yH20+4NH4NO3+H2O

The nitric acid in this method can be replaced by organic acids, such as formic acid, acetic acid, citric acid, lactic acid, with the advantages of moderate acidity and easy to operate; but, the expansive price of organic acids makes them hardly to be used in the mass production of AMT in industrial. However, although the nitric acid being used in the nitric acid neutralization method has the benefits of easy to get and low cost; but, because nitric acid has a strong acidity which will make the generation of tungstic acid colloid becoming easily, and introduces impurity of nitrate into AMT, thereby to decrease the converting rate and property of AMT.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate and Rewriting Paper

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 18 November 2016 15:58

- Hits: 1704

Ask: What is the relationship between ammonium metatungstate (AMT) and rewriting paper?

Ask: What is the relationship between ammonium metatungstate (AMT) and rewriting paper?

Answer: Nothing direct.

Ask: Then, why you put both of them together?

Answer: Because ammonium metatungstate is the raw material for preparing tungsten dioxide (WO2), while tungsten dioxide is one of the two material of rewriting paper.

Paper wasting is one of the biggest problems we meet in environment protection currently, we know that, the raw materials of papermaking are plant fiber (such as woods, bamboo, grass), mineral fiber (asbestos, glass fiber, etc), other fiber (nylon, metal wire, etc.), and the polymer material which get from oil cracking. At present, papers used for writing, painting and packing are still manufacturing from plant fiber, which will bring huge threat to environment protection.

Recently, one research team came up with an interesting solution – the rewriting paper, which is using two materials of tungsten dioxide (WO2) and polyvinyl pyrrolidone; this rewriting paper not only can save water, energy, space, but also can reduce the emissions of greenhouse gas; in addition, this kind of rewriting paper has non-toxic effect, and has been proved to be used for the field of medicine and food. The rewriting paper is through the appearing and fading of blue to realize function of rewriting, if this material is exposed to UV light for more than 30 seconds, the color will automatically become dark blue; while, the blue will fade when exposed in the outdoor for a or two days, or heated; moreover, the addition of polyvinyl pyrrolidone can extend the duration of blue to 10 days, and increase circulation writing to 40 times.

Ammonium metatungstate is a kind of white or yellowish powder with water solubility, and the solubility can reach to 300g/100ml in the water under 20°C, an important tungsten compound in tungsten metallurgy industry. Ammonium metatungstate is mainly used for preparing tungsten oxide, such as tungsten trioxide (WO3), tungsten dioxide (WO2), blue tungsten oxide (WO2.9) and violet tungsten oxide (WO2.72), tungsten powder, tungsten based carbide; furthermore, AMT is also used in many kinds of petroleum and chemical catalysts, the main raw material of W-based catalyst for oil refineries.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing WO3-Fe2O3/TiO2 Composite Photocatalyst

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 17 November 2016 16:58

- Hits: 1642

WO3-Fe2O3/TiO2 composite photocatalyst is an inorganic material which can be used in the degradation of pollutants in the environment, the new type of photocatalyst. Traditional photocatalyst is mainly based on titanium dioxide (TiO2), which has the advantages of chemical stability, high catalytic activity, strong oxidizing power, non-toxic, low cost ect.; however, because the spectral response range of titanium dioxide is really narrow, and thus it can only utilize the ultraviolet light (wavelength less than 387nm), which has become the bottleneck and limited the application range of titanium dioxide. Therefore, the development of photocatalyst which has high activity and can utilize the visible light is of very large economic and practical value.

WO3-Fe2O3/TiO2 composite photocatalyst is an inorganic material which can be used in the degradation of pollutants in the environment, the new type of photocatalyst. Traditional photocatalyst is mainly based on titanium dioxide (TiO2), which has the advantages of chemical stability, high catalytic activity, strong oxidizing power, non-toxic, low cost ect.; however, because the spectral response range of titanium dioxide is really narrow, and thus it can only utilize the ultraviolet light (wavelength less than 387nm), which has become the bottleneck and limited the application range of titanium dioxide. Therefore, the development of photocatalyst which has high activity and can utilize the visible light is of very large economic and practical value.

Research has found that, doping metal ion is an effective way to make TiO2 showing photocatalytic activity under visible light. Generally believed that the metal ions into the TiO2 lattice can be introduced impurity levels in the forbidden band, the band gap is reduced, so that the valence band electrons after receiving a large optical excitation wavelength, the first transition to impurity energy level, by once again absorb the energy, the transition from the impurity level to the conduction band, thereby reducing the energy required by stimulated to achieve so that the spectral response range of TiO2 photocatalytic move to the visible region.

An invention has pointed out a method to prepare WO3-Fe2O3/TiO2 composite photocatalyst, which bases on the tungsten source of ammonium metatungstate (AMT), with the steps as following:

1. Add water into the ammonium metatungstate solution according to the weight ratio of WO3: water (1:6〜7);

2. And then add ferric nitrate [Fe(NO3)3•9H2O] according to the weight ration of WO3: ferric nitrate (5〜7:1 ) to dissolve and get the impregnation liquid;

3. Add TiO2 powder, which is anatase type with BET specific surface area of 80〜150m2/g, according to the weight ration of WO3: TiO2 (1:6〜7), then dry the mixture at 100°C for 4~6 hours;

4. Calcine the mixture at 580°C〜780°C for 5 hours to finally get WO3-Fe2O3/TiO2 composite photocatalyst.

Compared with the composite materials which dose not dope with metal ions, WO3-Fe2O3/TiO2 composite photocatalyst is showing a better photocatalytic ability; at the same time, the doping of WO3 and Fe2O3 with specific lattice structure is actually modifying the TiO2 particle, thus to extended spectral response range of TiO2, and make it can be widely applied in the fields of environmental purification.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.17th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 17 November 2016 09:36

- Hits: 1240

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.17th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com