Notes on Good Riveting -- Back Riveting -2

- Details

- Category: Tungsten Information

- Published on Monday, 08 December 2014 09:24

- Written by Sherry

- Hits: 503

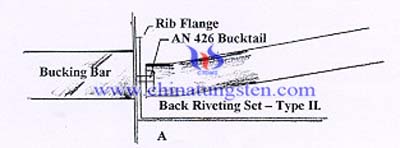

Type II

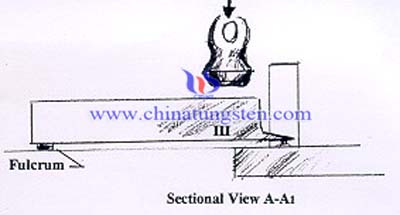

Type III

If the builder is working alone, sometimes it is difficult to judge when the backriveting set/gun is square to the surface being joined.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Back Riveting -1

- Details

- Category: Tungsten Information

- Published on Friday, 05 December 2014 08:53

- Written by Sherry

- Hits: 452

Back riveting is a method of setting rivets, usually in a skin component, by striking the buck tails with a special gun set while the flush head is securely supported in its dimple or counter sink by a steel plate or bucking bar.

Control surfaces are usually back riveted using a horizontal steel plate mounted on a table. The skin rivets are held vertically in their holes with thin Scotch Magic tape or fine Mylar tapes over the heads. The internal rib or stiffener is placed over the rivets and the special gun set is used to sequentially set these fasteners. Note: try using all RV-Workshop Learning centre back riveting sets.

Type I

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Bucking Bar Orientation

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 December 2014 09:12

- Written by Sherry

- Hits: 486

1. Rest bucking bar on inserted rivet and try to locate its point of balance.

2. With gun set in place, use bucking bar to push rivet (and gun assembly) outward. Bucking bar will then register at right angles to the rivet as it comes to rest on the aluminium.

3. Push rivet back into place with gun set and reposition bucking bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the bucking bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'

5. Duration of riveting is determined by experimentation with a test piece or previous experience.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Bench Riveting

- Details

- Category: Tungsten Information

- Published on Thursday, 04 December 2014 08:54

- Written by Sherry

- Hits: 516

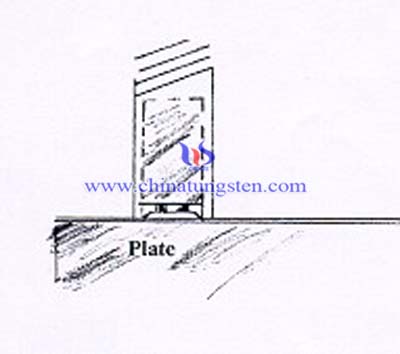

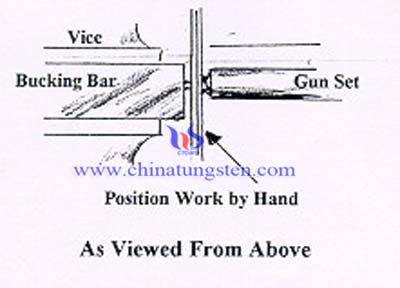

Often components are more easily riveted as sub-assemblies (off the airframe). A workbench allows components to be positioned and secured optimally for joining.

The bucking bar may be secured in a bench vice and, with the components positioned by hand, rivets are set with a gun held in the other hand. The main advantage here is that the bar is stationary and the components may be more easily held and positioned for riveting.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Gun set

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 December 2014 08:59

- Written by Sherry

- Hits: 457

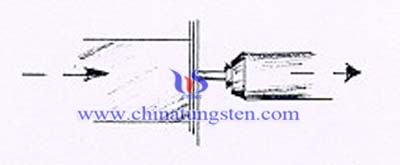

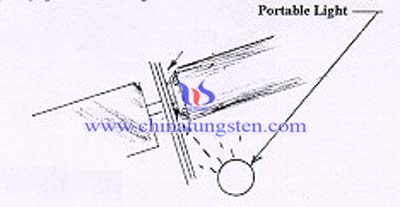

Rivet gun set is correct for the size of the rivet and is positioned at 90 degrees to the work surface. With universal rivet sets, the reflection of the gun set in an aluminium surface will give the impression of a continuous straight line with the gun set itself if positioned at 90 degrees.

Also, light reflecting from the edge of the rivet head will appear as an even line around a properly positioned gun set.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com