High demand for mobile devices, sapphire plant has not been "harvest"

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 04 June 2014 14:42

- Hits: 2411

LED high demand in China , driven by the increased demand for sapphire five consecutive months , but the average price does not rise, 2-inch and 4 -inch substrate prices slipped , mainly because customers did not significantly profitable LED epitaxial plant upstream sapphire plant difficult to price increases.

Sapphire rising Chinese mainland market demand in April reached 5,000,000 (converted 2 inches ) , mobile devices and LED applications each half. Demand for mobile devices surge 85 percent last month , including mobile phones lens cover , chassis and home button ; LED demand will surge 25 percent last month .

Sapphire Taiwan factory mainly supply LED demand , saw the growth of the China market in recent years, including Rui Jie , Zhao far , Xin Jing mainland expansion were drilled to circumvent the 11% import tariffs, the main customers for the upstream LED epitaxial plant such as Taiwan Epistar regions and in the new century , Sanan continent and BDO Runda . Sapphire ingot plant operations are divided into slices , PSS three blocks, which focused on profitable ruijie best PSS ( patterned substrate ) OEM , Zhao Xin far and Diamond except PSS processing, but also engage in lower profits ingot and slicing .

Rui Jie said , PSS substrate can enhance LED luminous efficiency, the current proportion of customers using the PSS board has up to 90% or more. So this year, driven by sharp McNair monthly revenue record highs.

In response to customer demand, the Czech Republic has been a sharp expansion plans in June , and 4 -inch substrate -based PSS , saving more than the 2-inch substrate production costs ( about 30% ) for the customer , is expected to force up the goods well . Legal estimate , Rui Jie in the second quarter revenue is expected to record high this year, will grow quarter by quarter .

Although the sapphire substrate demand is good, but UBS Securities, said in April the Chinese mainland market, the average unit price of the sapphire substrate was slightly down compared to March , is currently just under $ 20.

Epistar chairman Bingjie earlier also said that due to the epitaxial plant profitable flip is not yet clear , it is difficult to price increases upstream sapphire substrates .

In addition to the use of LED sapphire substrate , the mobile device market is growing dramatically .

Currently include phone camera , home button , the phone panel glass demand growth has been driven by demand in China in April sapphire substrates for mobile devices surge 85% ; recent market rumors , Apple iPhone 6 will use the sapphire glass , mainland China and millet machine Cool is also expected to follow up , if we seize Taiwan plant -related business opportunities, revenue for the second half to inject not small.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire industry's future development space

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 03 June 2014 15:11

- Hits: 2486

Currently sapphire crystal growth method is widely used Kyropoulos , accounting for about 70% of global production. Apple 's agreement with GTAT mainstream will not push the heat exchange in front of everyone , its advantage lies in : a higher degree of automation, high crystal large timber rule , GT owned Hypersion ion technology patents after cutting is expected to reduce the scale of the cost cutting . For now, Kyropoulos still relatively cost advantage . Prices rose from the bottom of the substrate , the basic stability of prices is expected over the next four -inch tablets will be stronger than 2 inches over from 2 inches to 4 inches is a big trend. Supplier to Apple hard sapphire material prices rise , the price if more than five apples may reduce the amount of dollars , so expect a lot of use after the sharp rise in prices of Apple Logic does not exist . If they can enter the apple industry chain , you can enjoy a substantial volume product , if the company then has a cost advantage , can achieve substantial growth in profits .

Sapphire future development of the industry is vast , raw materials of high purity alumina , diamond cutting wire , tungsten and molybdenum crucible , graphite crucible , abrasives, polishing liquid and other industries will benefit. A 2-inch piece diamond wire consume 2.5-3 meters, according to 2013 Global 130 million 2-inch pieces calculations, the value of diamond wire consumed about 244 million yuan . If used in all future Apple screen sapphire , market capacity increased by 7 times the value of the diamond wire required corresponding to 20 billion yuan. If other smartphones than Apple also promote the sapphire screen applications , the demand will continue to increase , sapphire with a diamond wire market over ten billion .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

LED Lens Product Diversification Is Not Standard Enterprise Disorderly Melee

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 30 May 2014 15:57

- Hits: 2396

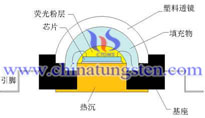

The main role of the lens of the LED is also applied to the LED light source is intensity distribution of secondary optical design. After the lens factory got its light -emitting shape  type were analyzed according to the light intensity distribution tailored to customer requirements , the most critical parameter is the light angle, apparently speaking generally opt for the spotlight mostly small angle , and spot lights and light boxes on You must select a wide angle .

type were analyzed according to the light intensity distribution tailored to customer requirements , the most critical parameter is the light angle, apparently speaking generally opt for the spotlight mostly small angle , and spot lights and light boxes on You must select a wide angle .

In addition to the light angle, the design also need to consider brightness , spot illumination, uniformity and other parameters, in addition to the material and the temperature is too etiolated also have certain requirements .

Diverse lighting solutions led to the diversification of the lens factory product, so the cost of lenses lens manufacturers are not large-scale production of natural difficult to have a big decline. Deeper reason also lies in lack of disorderly competition throughout China LED industry standard lead .

Admittedly , some products have been standardized current trends , such as lamps , generally in accordance with the length of 0.6 m , 0.9 m , 1.2 m , MR16, PAR30, PAR38 there are standards, but are only appearance requirements , specific requirements such as light efficiency, Color still each have their own standards, the lens factory and only for sections of the light source and the lens tailored to customer requirements .

"Now with the light 100lm lights have to do with 140lm light street lamps do have, obviously not the same as with the lens . " Lihua Hu stressed .

Indeed, from the current lighting price, the cheapest you can reach one yuan / W, the most expensive can even reach $ 7 / W, various grades of natural lighting customer demand for lenses are not the same .

" Many companies are more sensitive to price , although our offer is not very high , but there are customers willing to buy a cheap lens making materials outlet . " Xue Teng said this seemed a bit helpless. Indeed, there is now Zhongshan lenses offer up to 7 points / month, while the average angle lens also a few quotes / month .

Reporters noted that less than half of these cheap lens prone to yellow, or even the bottom of the melting phenomenon seriously affect the quality of the lamp. Cheap lens manufacturers generally do not own optical R & D team , thanks to lens development plagiarism . No IQC nor QC, not even the quality checks. They did not clean room, often done in the open large metal shed , let alone the production process for anti-static , anti- dust treatment . Replaced once every hour there is no finger sets to prevent impurities entering the lens appear blackspots affect the appearance.

Meanwhile, cheap lens and lens regular factory produced materials used are very different. Good lens is generally made of imported materials. " transmittance of imported materials will be better , the best materials such as Mitsubishi transmittance can reach 90 %, but made only 80 percent light transmittance . " Sheng Hardware Lighting Parts Factory director Liangwen Biao said . Reporters from the market research you can see the thicker lens transmittance requirements lower , generally 2 mm acrylic light transmittance requirements of 93%, PC 89% -90%. In addition transmittance also some customers have special requirements , such as requiring the use of diffusion material or have a certain fire rating requirements of the material.

"import material in the curing, a better performance aspects of yellowing can ensure heat resistance, the production process less dust, is not easy to form a black dot . " Eliza Hu said based on the production process, they are carried out of internal stress , the treatment of 90 ° -95 ° acrylic oven baking , PC at 120 ° -150 ° oven baked to release the internal stress , so their products are emboldened to provide 3-5 year warranty.

Indeed, the injection time is also to ensure the quality of the lens a key point , because the injection time is short lens is not easy to release stress , it is easily deformed. According to the reporter , the general quality assurance of each injection molding machine daily lens manufacturers only produce an average of 8000-9000 lenses , but regardless of the quality of some of the manufacturers Zhongshan daily average for each injection molding machine can produce tens of thousands .

The most troublesome problem of internal stress , when using a lens just can not see , but generally over half a deformed, yellow , and so on a series of questions followed . As the saying goes you pay for it as long as the low-end lighting factory price low , black spots , deformation will occur after six months , the yellow light even with a series of questions so the deviation is not a problem .

In addition to the above, the lens factory hardware capacity requirements are high. Manufacturers are generally imported injection molding machine, the best equipment in Japan and Germany , once again also Taiwan equipment , generally do not consider domestic equipment. And be sure to use an optical injection molding machines, injection molding machines , but this is generally relatively small size , capacity for mobile phone housing for ordinary injection molding machines for the production capacity will be a lot worse.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

LED Flashlight:Neglected "Blue Ocean"

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 30 May 2014 15:49

- Hits: 2446

In fact, the domestic packaging companies rarely develop light sources for LED flashlight features. This is mainly because the current competition in the domestic market, but also LED flashlight  is not heating up.

is not heating up.

In addition to architectural lighting outside and as the largest market, consumer portable lighting market in particular is one of the LED flashlight market, due to a major industry giants began to be neglected, but there is no competition bulb, fluorescent light so intense.

According to Engineering LED Industry Institute (GLII) survey data, although a quarter of China's LED packaging industry output value reached 13.72 billion yuan, an increase of 23.2%, but the overall increase in volume and a drop in price is still the main style LED packaging industry, some product prices fell more than 30 percent year on year, or even higher.

In the case of product prices fall, more and more companies began to notice the package has a huge market potential for LED flashlights.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

LED Engineering Exhibition 2014:Predictable Package into The Era of Large-Scale

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 29 May 2014 15:51

- Hits: 2454

With the LED application market demand are rising downstream pull , LED midstream package good day finally came last year , product demand continues to rise, many companies Fun Fun also accelerated the pace of expansion .

came last year , product demand continues to rise, many companies Fun Fun also accelerated the pace of expansion .

"The current pattern of the whole package is still in the stages of change market , strong downstream market demand continued expansion of domestic packaging manufacturers , packaging companies decisive factor in the future competition will be the management , cost control and the size and brand . " participated in last year's LED Lighting Fair 2013 Engineering Taiwan shares GONG Wen Jing , general manager of the view that although the current LED packaging industry trend is clearly the bigger , but the overall market structure variables are still compete for the next two years between the LED packaging companies war will be more intense.

Engineering LED Industry Institute (GLII) statistics show that in 2013 China's packaging industry reached 47.3 billion yuan , an increase of 19 % compared with 39.7 billion yuan in 2012 .

Where last year 's leading packaging companies in the upstream and downstream enterprises took the lead stand up , contrarian growth , in addition to benefiting from rising demand for downstream applications market growth, packaging companies to increase their capacity to release , especially to increase the research and production of non- white device power lighting did not .

Major packaged device manufacturers responsible people have told reporters that this year's orders and a steady increase compared to last year , in which the power devices and downstream COB light source lighting manufacturers gradually being accepted and recognized .

Engineering LED Lighting Fair 2013 exhibitors - Hubei Peter Pang Cheng Electronics Co., Ltd. Deputy General Manager learn that the future will be more and more applications COB , COB products in terms of power will become increasingly high, and light efficiency and cost areas will do better.

In recent years , domestic packaging manufacturers make full use of their localization and price advantage, through the gradual introduction lighting supply chain , improve product quality while gradually seize market share of imported components.

The upcoming September 26, 2014 -28, first moved to Canton Fair Pazhou Pavilion exhibition staged in 2014 Engineering LED packaging companies will continue to work as well as front-line leader in all market segments packaging business representatives , focusing on the promotion of emerging markets this year, the package includes COB, flip flip and trends , such as the market mainstream products .

In the same time, the rapid development of the industry , packaging manufacturers rely on technology and scale advantages are gradually squeezing the living space of a small factory , packaging industry reshuffle , the integration is deepening among .

Liu Yusheng that the next package will accelerate the industry reshuffle , capacity dominant companies will occupy more and more market share.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Enterprises to Accelerate The Pace of Expansion Integrated LED Package'Incomes And Increased Profits."

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 29 May 2014 14:43

- Hits: 2444

With the gradually released annual report , LED listed companies generally came out from 2012 , " income does not increase profits" dilemma in . Showing a revenue and net profit growth of double  gratifying situation.

gratifying situation.

Upstream and downstream of epitaxial silicon as lighting, display intermediate application convergence, the most directly felt encapsulated stimulating effect downstream lighting needs , but also the biggest beneficiary.

"The most direct reason is that last year's good harvest package downstream lighting, display and backlight -than-expected growth in consumer electronics development . " Zhang standard LED Engineering Research Institute (GLII) research director , said that with the gradual increase domestic packaging companies and technology, the high cost of domestic devices has been recognized by the majority of enterprise applications , has occupied the Taiwan plant and a number of international plant of the market.

Pace overcharged " bucket 35 " of packaging companies have taken advantage of accelerated expansion, integration , extending downstream packaging plant more and more cross-border effect also was apparent in 2014 in the first quarter .

BOCI Securities researcher Li said, " 2014 will be the first LED lighting in the true sense of the industry chain , midstream will be subject to the downstream demand pull . "This fiery performance directly reflected in the annual results of listed companies in the package .

Reflected in the capital markets since the second half of last year, institutional investors, listed companies on the packaging field research began to frequent them .

Ping An Securities research report , LED 2014 will be a year-round throughout the plate , in the light of heavy volume , the background of rapid growth in demand , many companies will usher in margins and ROE of inflection . LED packaging company needs midstream mergers and acquisitions this year, and most of them have to refinance , because the profit base is generally not high , so the corresponding results for considerable flexibility , the possibility of a dark horse emerge relatively high .

Where last year 's leading packaging companies in the upstream and downstream enterprises took the lead stand up , contrarian growth , in addition to benefiting from rising demand for downstream applications market growth, packaging companies to increase their capacity to release , especially to increase the research and production of non- white device power lighting did not .

" Downstream from now larger than the bulb, lamp, panel lights , and other products are mainly applied domestic devices. " Bo , deputy general manager Wang Peng said photoelectric lion , which is undoubtedly the domestic devices is a significant market opportunity last year, many packaging companies are very tight supply white device .

On the other hand , domestic packaging companies with technological advances , product development strength, the quality of domestic devices significantly improve downstream applications manufacturers also more cost-effective homemade device to accept the past, Japanese and Korean companies were firmly in the packaging plants and Taiwan high-end device control some areas , but now they are domestic packaging companies into its supply chain.

" middle, occupying the majority of the domestic packaged devices in the domestic market , accounting for China 's imports of packaged devices quickly reduce the proportion of domestic components occupy the major domestic market share. " Dr. Engineering LEDCEO Xiaofei believe that there is a part of the domestic packaged devices have been exported to foreign countries, China began to move toward the global LED packaging .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

CLEAR Plans to Test Results Released LED Panel Lights Do Not Meet The Requirements of DLC

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 28 May 2014 14:30

- Hits: 2564

Recently, sponsored by the Engineering LED, joint G20-LED summit, the Chinese LED lighting CLEAR third party testing organization plans to test detects common Reed released the eighth round market sampling tests results came back .

party testing organization plans to test detects common Reed released the eighth round market sampling tests results came back .

Test data from a sample of 12 models panel light requirements and DLC contrast , the compliance rate is very low single parameter , a product does not meet the requirements of DLC for the product as a whole .

The LED panel light detection based LM79-08 standard test method , the test project covers a total luminous flux, luminous efficiency, correlated color temperature , color rendering index , R9 value, total harmonic distortion, power factor , etc. , and the test results with the U.S. DLC request for comparative analysis .

The detection of the selected sample , both the domestic electricity market vendors channel top-ranking brand panel lights, a total of 12 models were from 12 different manufacturers . Due to the size of the light-emitting surface of each sample is inconsistent, the standard size is not DLC specification requirements , so there is no way to match the exact product categories.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Engineering Exhibition 2014 LED:LED Integrated into The Main Theme of The Industry Differentiate

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 28 May 2014 14:20

- Hits: 2404

China LED industry as technology advances, the cost of further reducing the volume and rapid growth in the downstream market for lighting applications and entered a rapid development period . Industry  chain River out of the doldrums all aspects of production and sales continued to grow, corporate profitability has started picking up .

chain River out of the doldrums all aspects of production and sales continued to grow, corporate profitability has started picking up .

From just past the first quarter of 2014, industry performance, upstream epitaxial chip companies continues to improve capacity utilization , production of major chip companies are still tight, chip products in short supply.

"Technology and the overall strength of the formation of the future of chip scale enterprises have to face barriers to competition . " Edge Difei that there is no scale chip companies can not do the best price , naturally can not survive the fierce market competition and development.

Chip companies large and packaging manufacturers signed a supply agreement to form a strategic alliance to become more popular this year .

Many industry insiders believe that the second half of the chip supply remains tight , this strategic alliance for the chip and packaging companies are good , since such cooperation may be more.

Midstream packaging industry after years of development , now has a considerable economies of scale , to become one of the world's leading LED packaging production base, occupying the majority of the domestic packaged devices domestic market share of imported packaged devices in the Chinese market quickly reduce .

A quarter of packaging companies also continued last year's good times , remains a simultaneous increase in revenue and net profit . Meanwhile, with a variety of technical courses and package technology advances, flip, no packaging, etc. abound.

Downstream applications this year , due to the lighting needs at home and abroad dual heat , combined with the implementation of national local government tenders , Guangdong , Fujian and other significant acceleration , LED lighting, public outreach is still hot in 2014 , while in the hotel , the field of LED lighting Chaodeng replace also become a trend.

Engineering LED Lighting Fair 2013 exhibitors - Sunshine Lighting (600261.SZ) Yong , general manager , said the official , LED lighting as a mainstream position has been determined, essentially 100% LED outdoor applications , business according to 80% of new project with LED, home to 90% of new products is the use of LED.

Consolidated first half of this year , LED industry still brings up the chain of mergers and acquisitions , price war, war and other traditional channels, magic , more focused on the fast growing trend of LED lighting end-market demand, the price for the market . Expected in the second half of 2014, this trend will continue .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to bite under the Channel LED piece of "fat"

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 27 May 2014 16:19

- Hits: 2411

More low-profit projects face channels , many businesses have expressed their " powerless " , still adhere to the " do not abandon, do not give up " principle , LED era lighting let us see how the performance of the Channel how industry experts ? commentary .

the " do not abandon, do not give up " principle , LED era lighting let us see how the performance of the Channel how industry experts ? commentary .

Age of the Channel LED Manufacturers Directly Involved

The era of the traditional lighting of the Channel and LED lighting era made a comparison: In the era of traditional lighting , lighting manufacturers usually completed in conjunction with the dealers , only a handful , such as the Olympic Games, World Expo , the Games because of the tender requirements such as high the need to work directly with manufacturers . In the LED era , due to the government's promotion efforts, a growing number of outdoor projects and municipal reconstruction project by the manufacturers directly involved , reducing the dealer link , greatly increasing the profits of manufacturers , making the project the channel has become a lighting industry ' fat ' .

For manufacturers direct access to the Channel this point , in the original works , such as mode of direct marketing agency , to operate the project brings more possibilities, more space. existing traditional channels of cooperation projects , relatively simple way , engineering agency funding pressure, project follow cumbersome. Engineering channels and circulation reduces the risk in the project operation, ultimately, more successful profit gains .

How The Channel Stage Performance ?

Engineering channel LED era with traditional channels , there are some differences , then how the Channel LED performance under this mode of operation and now it ? Profits and how ?

Profit project channels a certain stage is relatively lower . The main factors leading to change are: First, the intense competition in the market ; Second , LED market matures , the price system is also becoming stable . now works profits decline : the previous works in product pricing by 50 points or more , and now some of the projects are basically not very profitable , everyone grab one , this is the result of competition . Large projects are generally tender , the fight is their strength . Because the owners may specify a brand or set up some special ( standard ) threshold, which allows general contractors can not intervene ; while for small projects in general , there is not much special requirements, we can go for a relative pressure also small . As engineering problems of payment , multi- contract to go, ordering the payment of part of the goods to pay part of the completion of the payment of part of the point is that there are about 3-10 shelf aftermarket gold, basic after-sales back section more difficult, it also works when you quote need to consider the cost . engineering market with high return characteristics, but high returns are often associated with high risk , the risk of investment in various sectors and to face the pressure of the flow than normal and retail channels is much greater, regardless of the date of China 's LED lighting or other companies, this channel is the LED lighting project risks and opportunities.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

2014 Sapphire Dan Changjing Furnace Go

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 27 May 2014 16:09

- Hits: 1357

2013 domestic sapphire furnace equipment manufacturers anxious awaits dawn , although ingot prices from![]() early 2013 began to gradually pick up, but early overcapacity can still waiting for the market to digest the growth of the LED chip . This party is the utilization of a gradual recovery in domestic MOCVD machine , there upstream equipment factory orders still failed to get the real feed their families .

early 2013 began to gradually pick up, but early overcapacity can still waiting for the market to digest the growth of the LED chip . This party is the utilization of a gradual recovery in domestic MOCVD machine , there upstream equipment factory orders still failed to get the real feed their families .

Touches on the window film market for field use sapphire material being widened , from camera to Apple 5S bonnet of the home button , Apple last October GTAT got three sapphire orders , be given the sapphire market gust of warm air, but whether there how many domestic plant can have a share , probably still needs our common efforts and innovation.

Let's look at 2013 , what kind of market information transmission and trends :

4 inches above the replacement rate 1.LED chip rapid increase domestic MOCVD new models and the existing 2-inch machine upgrade , Samsung and other foreign chip plant began mass production as 6 inches , 4 inches unit costs relative to the 2 absolute advantage inches more prominent. Reason to believe that this year, for the assessment indicators in LED crystals are converted into 4 inches , which requires the development of large-capacity single-crystal furnace can keep up as soon as possible . (> 120kg, there must be a stable and reliable solution for our current and previous rounds of simulation experiments show the 125 kg level has greatly improved the overall cost than 85kg)

2 , where is the sapphire cost ? Many customers are more concerned about the ingot market prices , without considering the tariff and subsidy cases, the decision is nothing more than the real cost of the following three points : equipment utilization and crystal yield , unit energy consumption , mainly life and cost thermal field components. Who can make a breakthrough and innovation above elements will occupy a very favorable competitive position.

3 In the window film market , if the phone screen really spend sapphire , sapphire it would be a subversion of industrial production , the vast majority of equipment manufacturers actually do not have large quantities in this application , low-cost technology model , the industry is really no need also entangled in the GT 's "Ruby" problem , at least for now they are the only one to really get the order window film plant. We believe that the need for the existing equipment technology roadmap , new materials and processes in order to make efficient integration of real customers have the confidence to make the window film release orders for sapphire . The research in these areas is precisely the weak link in the chain of the domestic industry , the domestic sapphire plant to be considered more in the long run , the system in terms of cooperation on downstream . In accordance with the sapphire cost today , most domestic mobile phone manufacturers are also difficult to accept to replace the sapphire glass screen.

Let's look at Sapphire crystal furnace technology future trends : sapphire furnace market will be more segments : LED applications and window film will have more targeted models.

1 more emphasis on traditional techniques dig stick quantity , unit cost, crystal size , EPD and other indicators, equipment manufacturers lack the quality of the crystal growth process understanding ; With power and brightness LED chips in terms of continuous improvement , sapphire lining for chip plant optical , stress midsole material performance requirements will be more stringent , long crystal manufacturers in the process for material performance impact needs to do more research. For example, the impact of annealing time and temperature stress release , the seeding process for the control of crystal defects , which requires equipment manufacturers to develop a more flexible and stable single crystal furnace , crystal growth technology enables staff have sufficient room for adjustment , the characteristics of the material itself of the single crystal growth furnace on the thermal field deformation determines the long-term use and the attenuation , the future development direction of the single crystal furnace power control precision, and independent thermal field phasing control , intelligent power adjustment and prediction there is a great need to improve the space .

2 Even in the field of window film , the market for equipment made a completely different direction, such as the current camera ripe bonnet and fingerprint recognition , a small area of its own , for the existing 2-4 inches of substrate utilization higher cost of materials to meet the existing models ; but is widely expected mobile phone screen applications , the new generation of crystal growth process route , using energy-saving thermal field of new materials and other aspects have yet to be industry colleagues to work together. Finally , said that large-scale sapphire production automation equipment requirements will be higher, including automated seeding stage and late stage technology thermal field after using automatic adjustment, the current control of our ongoing research and development of artificial intelligence .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com