Using Molybdenum Oxide as Hole-Selective Contact in Solar Cell Hits 23.5% Efficiency

- Details

- Category: Tungsten's News

- Published on Tuesday, 25 February 2020 22:53

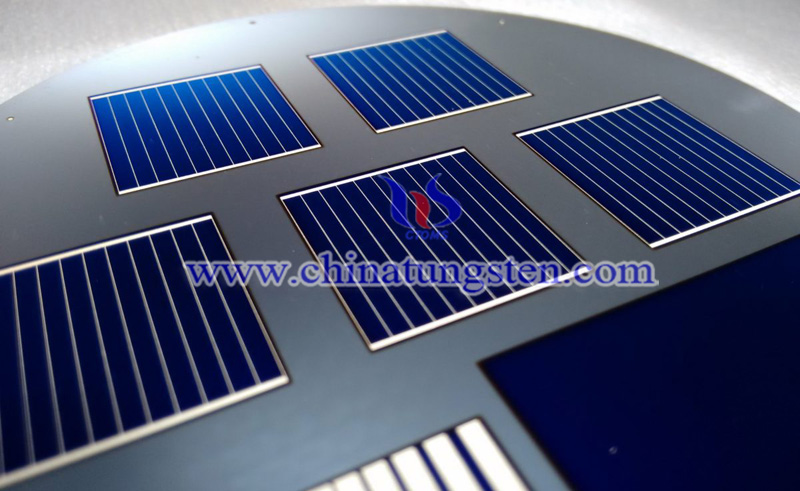

Scientists at Switzerland's École Polytechnique Fédérale de Lausanne (EPFL) in Lausanne use molybdenum oxide (MoOx) as the hole-selective contact in crystalline silicon heterojunction solar cell, which can make the cell efficiency reach 23.5%. Related research results were published on Nano Energy and Science Direct.

According to the researchers, molybdenum oxide has been used as a carrier selection layer and crystalline silicon substrate in organic, inorganic, and thin-film solar cell due to its high work function and bandgap - was used in a device structured in such a way to enable it to fully benefit from its improved transparency compared to p-type hydrogenated amorphous silicon. Scientists said that the MoOx can rival traditional contacting schemes in spite of its lower level of optimization.

The research team found that thinner layers of compounds can lead to better performance, as dense contact reactors enable higher selectivity and passivation capabilities as well as good cargo transportation. Experiments show that the highest efficiency of this series was obtained for a 4nm-thick MoOx layer and a 6nm-thick intrinsic hydrogenated amorphous silicon ((i)a-Si:H) [layer]. Photoluminescence images and measurements of volatile organic compounds at high illumination demonstrate the effectiveness of thinner layers of the compounds.

The EPFL team found the tiniest layers of the two compounds resulted in the best performance, as the thin contact stacks allowed for high selectivity and passivation and good charge-carrier transport. “The highest efficiency of this series was obtained for a 4nm-thick MoOx layer and a 6nm-thick intrinsic hydrogenated amorphous silicon ((i)a-Si:H) [layer],” the researchers wrote.

Because the results of using (i) a-Si: H are quite extensive, the researchers processed a 4nm-thick MoOx layer. The layer (i) a-Si: H is 8nm thick. It has been verified that the cell efficiency is 23.5%, and the filling coefficient is quite high, about 82%. The researchers said that the solar cell's record efficiency was obtained without any masking or lithography steps, and it used a low-temperature screen silver plating method that produced about 3% of the shadow.

It is reported that researchers now plan to further reduce the thickness of the molybdenum oxide layer. They believe that before considering the large-scale deployment of this technology, the industrial feasibility and long-term stability of these devices must be studied.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com