Tungsten Carbide Powder with 3D Printing

- Details

- Category: Tungsten's News

- Published on Tuesday, 18 June 2019 18:27

Tungsten carbide powder used in global paints and coatings market forecasted to reach $262.5 billion by 2023, the market growth is driven by the increasing demand for painting and coating solutions from the automotive, electronic, and construction industries. Especially it’s important adoption in 3D printing.

The global 3D printing market is expected to reach $31,863.7 million by 2023. The key benefits of tungsten carbide powder associated with 3D printing, such as cost efficiency, single-step manufacturing process, and the ease of developing customized products, are expected to increase the adoption of 3D printing technology, globally, in the coming years.

Major opportunity identified in the tungsten carbide powder is the product adoption in 3D printing technology. Recent innovations and the commercial adoption of 3D printing technology have allowed for the processing of tungsten carbide powder. This offers new growth opportunities for the market. In February 2018, Dyze Design, a 3D printing accessory developer, launched a set of tungsten carbide nozzles for integration in numerous fused deposition modeling (FDM) machines. The successful integration of tungsten carbide powder in supply chain is offering lucrative opportunities to the market players for growth.

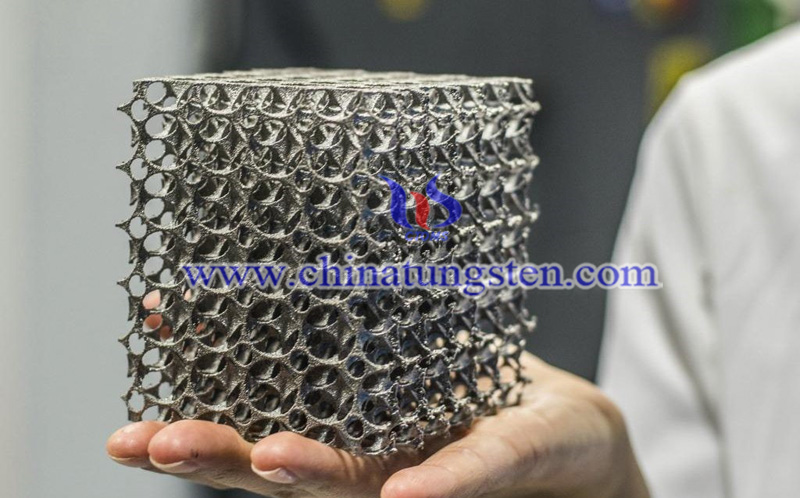

3D printing is an additive manufacturing process for rapid prototyping ceramic and metallic parts. Tungsten carbide powder must have a density greater than 50% of the theoretical density, 14.9 g/cc, for proper sintering and post-processing. Two approaches were assessed for feasibility and robustness: printing slurry into tungsten carbide-cobalt spray dried powder and printing a solvent in spray dried tungsten carbide powder that readily dissolves. For slurry administered to a powder bed of solid, spherical particles, it has been found that the resulting packing primitive packing fraction increases almost linearly with the volume loading of the slurry over a range of powder size. The increase in density is approximately half what would be calculated by assuming that the slurry fills all the porosity in the powder bed. The maximum green density achieved by printing slurry into a spray dried tungsten carbide-cobalt bed was 41%, midway between the lower bound calculated by assuming the vehicle in the slurry infiltrates only the large pores between the spray dried power and the upper bound calculated by assuming that the vehicle of the slurry also infiltrates the find pores within a spray dried granule.

In the past the addictive normal metal in the 3D printing is easily crack. Since tungsten carbide powder applied in 3D printing makes it more effective because it selectively joins powder particles with a binder, one microscopic layer on top of another and without any temperature fluctuations during printing. Intend to make 3D printing with better performance, researchers will investigate various tungsten carbide base powders that can be utilized in a binder jet 3D printing, as well as optimize the printing process and subsequent sintering and hipping. This research will enable tungsten carbide powder to expand its expertise in 3D printing and additive manufacturing process optimization.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com