Photovoltaic Effect of WS2 Nanotube Devices

- Details

- Category: Tungsten Information

- Published on Saturday, 05 November 2022 22:21

- Hits: 587

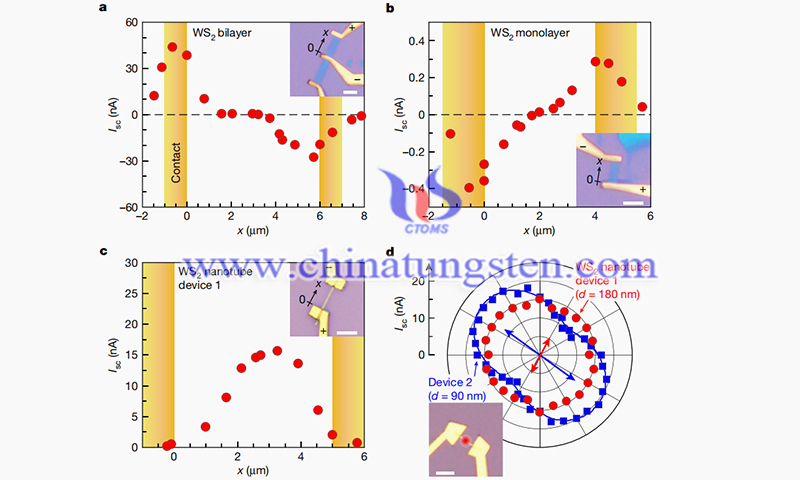

The bulk photovoltaic effect (BPVE) in WS2 nanotube devices is quite stable in terms of quality and quantity. The large decrease in the short-circuit current (Isc) with decreasing temperature cannot be explained simply by a decrease in the absorption coefficient, because the band gap is blue-shifted with decreasing temperature. Light with a wavelength of 632.8 nm (1.96 eV) almost resonates with the A-exciton of WS2 (a specific bonded state of an electron and a hole) and therefore produces the strongest signal.

Photovoltaic Effect of WS2 Bilayer Device Under Laser Illumination

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2022 21:28

- Hits: 678

The short-circuit current (Isc) under laser illumination is an important parameter for the evaluation of photovoltaic effects. We measured this current for WS2 bilayer device with different crystal symmetries. For each device, we scanned the laser spot from one electrode to the other to distinguish the BPVE from the Schottky barrier photovoltaic effect as well as the photothermal effect near the contact.

Enhanced Intrinsic Photovoltaic Effect in Tungsten Disulfide Devices

- Details

- Category: Tungsten Information

- Published on Monday, 31 October 2022 21:20

- Hits: 620

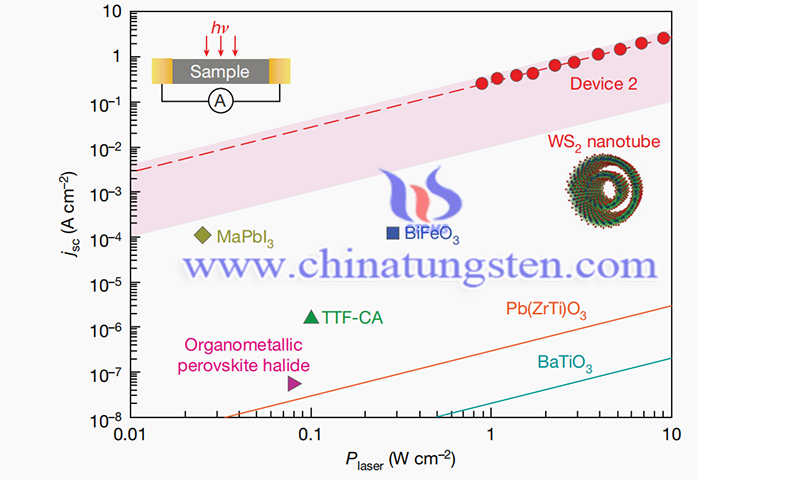

The bulk photovoltaic effect (BPVE) found in tungsten disulfide devices could further enhance energy conversion rates. The BPVE in conventional p-n junctions - where p-type materials (with excess holes) are adjacent to n-type materials (with excess electrons) - generates current through the light-induced generation and separation of electron-hole pairs. This BPVE is particularly important in energy applications, and its efficiency is now approaching its theoretical limit.

Titanium Oxide Tungstate Nanotubes Improve Fuel Cell Performance

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 October 2022 21:36

- Hits: 560

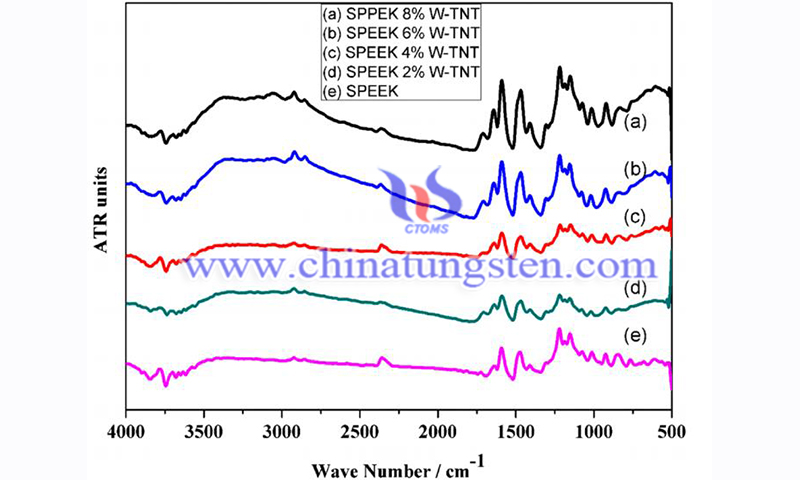

Titanium oxide tungstate nanotubes could improve fuel cell performance. The chemical oxidative stability of the tungstate-functionalized sulfonated poly ether ether ketone (SPEEK) membranes is one of the key requirements for the durability and performance of the fuel cells, which was estimated using Fenton's reagent method.

Tungstate Titanium Oxide Nanotubes Improve Ion Exchange in Fuel Cells

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 October 2022 21:28

- Hits: 640

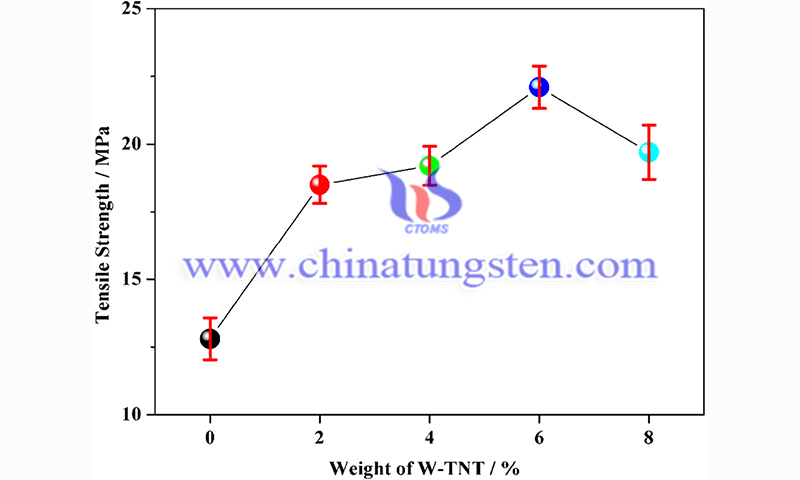

Ion exchange capacity is a vital property of ionic membranes, and this property is enhanced with the addition of ion-exchange materials. The IEC value of pure SPEEK membranes is 1.9 meq g-1 due to the contribution of sulfonate group (SO3H). increasing the content of tungstate titanium oxide nanotubes (W-TNT) in sulfonated poly ether ether ketone (SPEEK) membranes could improve the fuel cell ion-exchange capacity.

Tungstic Acid Titanium Oxide Nanotubes for Proton Exchange Membrane Fuel Cell

- Details

- Category: Tungsten Information

- Published on Friday, 21 October 2022 14:51

- Hits: 605

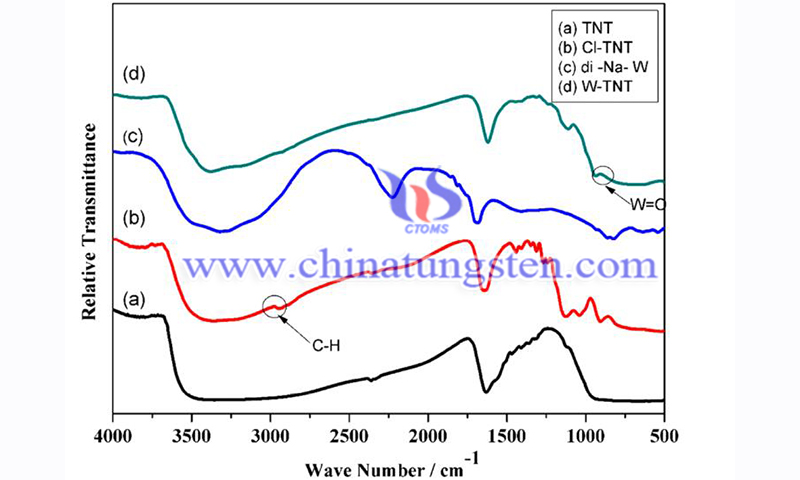

Among various two-dimensional materials, titanium oxide nanotubes (TiO2 nanotubes) are stable and environmentally friendly, and their electronic, optical, and dielectric properties can be tuned by surface modification. Researchers used tungstic acid covalently bonded to titanium oxide nanotubes (W-TNT) for the first time as an ion-exchange filler for the fabrication of proton exchange composite membranes. The tungstate group (H2WO4) contains exchangeable protons similar to the sulfonic acid group (SO3H) and can also be used as an ion exchanger.

Preparation of Tungstic Acid Functionalized Titanium Oxide Nanotubes

- Details

- Category: Tungsten Information

- Published on Friday, 21 October 2022 14:47

- Hits: 635

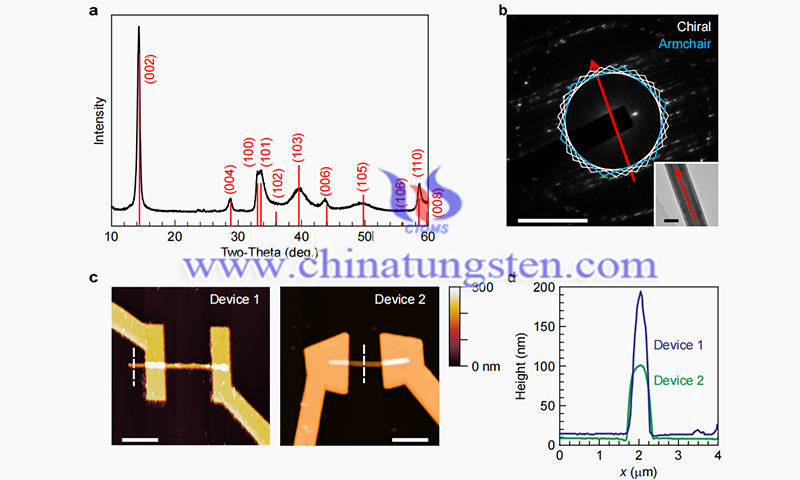

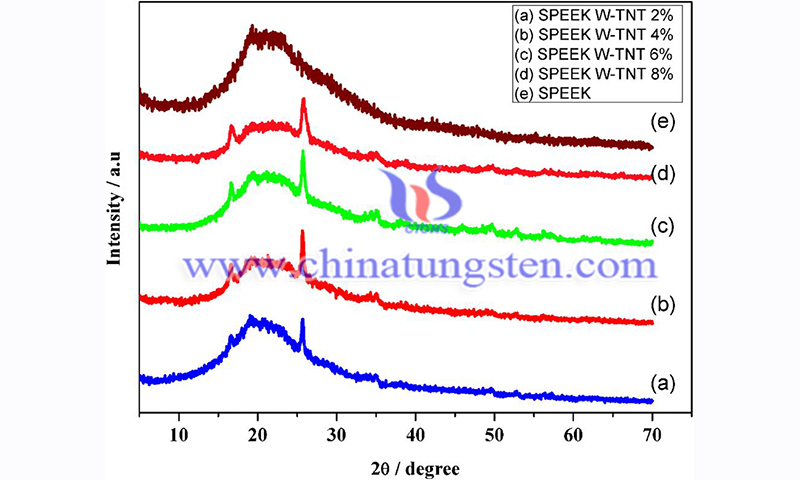

Titanium oxide nanotubes (TNT) were synthesized by hydrothermal method and covalently grafted with tungstic acid (ion exchange group) on their surface. The synthesized tungstate functionalized TNT (W-TNT) was characterized by SEM, TEM, and XRD analysis, and the successful grafting of the tungstate group was confirmed by FTIR and solid-state NMR techniques.

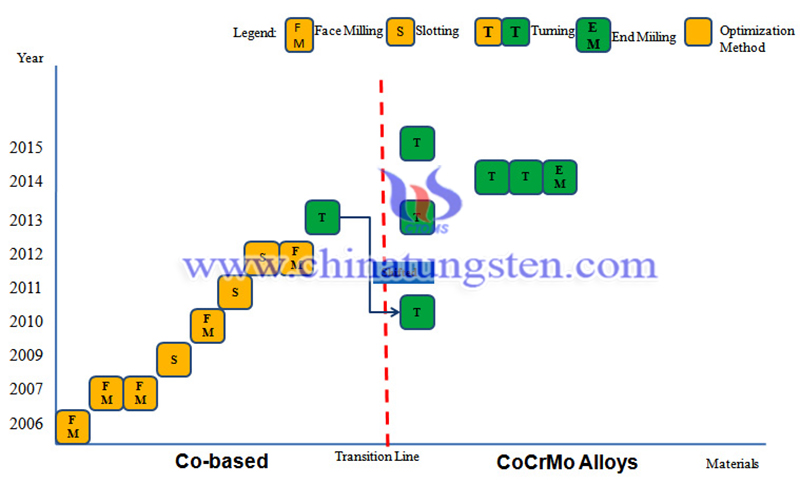

Tool Material for Machining Cobalt Alloys and CoCrMo Alloys

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 October 2022 16:40

- Hits: 685

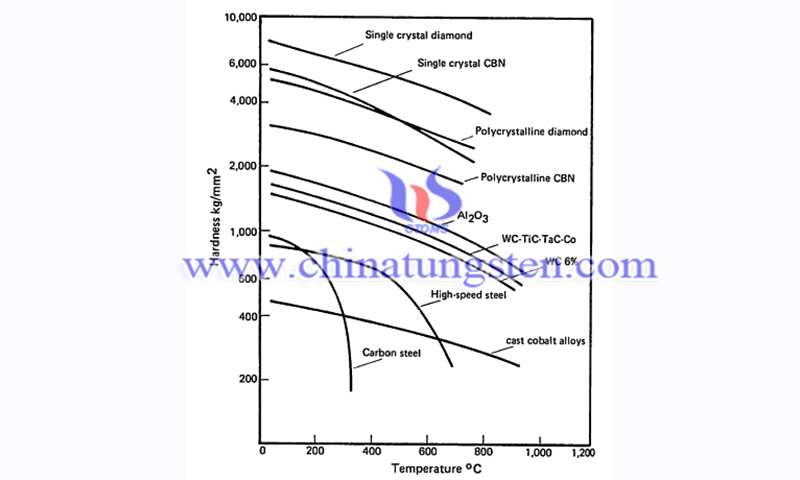

The cutting tool material is the most important aspect of the cutting process in machining operations, especially when machining difficult-to-cut materials such as titanium, cobalt alloys, and CoCrMo alloys, where high heat and mechanical stresses caused at the tool edge are major problems.

Coolants for Machining Cobalt Alloys and CoCrMo Alloys

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 October 2022 16:33

- Hits: 536

Many researchers have analyzed the effect of coolants on tool wear, cutting temperatures, and cutting forces when facing and turning cobalt alloys and CoCrMo alloys for machining surface integrity. Surface integrity is crucial for medical applications, especially for surgical implants and devices. Cobalt alloys and Co/Cr/Mo alloys machining operations typically generate residual stresses through the outer layers of the machined surface of the workpiece, and these residual stresses present a potential risk in terms of crack generation and extension and affect the corrosion resistance of surgical implants.

Research in Machining of Cobalt Alloys and CoCrMo Alloys—Ⅱ

- Details

- Category: Tungsten Information

- Published on Sunday, 16 October 2022 22:25

- Hits: 562

Time and cost constraints are necessary to reduce the manufacturing costs of Cobalt alloys and CoCrMo alloys. Some of these elements are obtained by mechanical machining and it is necessary to optimize the machining parameters for these products. Several researchers have conducted experimental studies on the machining of cobalt-based refractory materials in order to establish optimal cutting conditions for different cutting parameters. They have used several optimization techniques based on RSM methods, using sequential quadratic programming algorithms and Kriging interpolation to solve a constrained problem.

sales@chinatungsten.com

sales@chinatungsten.com