Properties of Tungsten Disulfide

- Details

- Category: Tungsten Information

- Published on Sunday, 11 September 2022 22:38

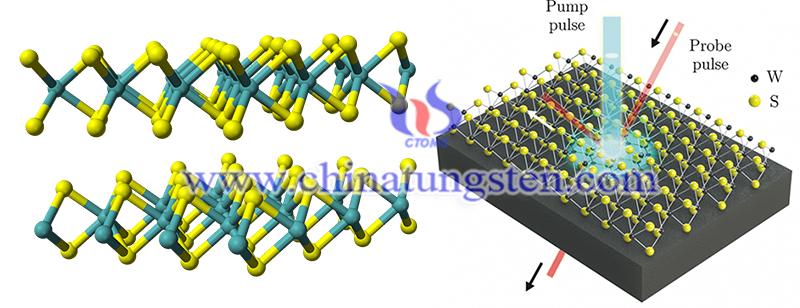

Owing to unique physical and chemical properties, transition metal dichalcogenides (TMDs) attract research interest. Among the family of TMDs, tungsten disulfide (WS2) has a unique band structure due to its semiconductor properties; i.e., its broadband spectral response characteristics, ultra-fast bleaching recovery time, and excellent saturable light absorption.

Owing to the influence of quantum confinement and interlayer interactions, indirect-to-direct bandgap transitions will occur when the thickness of WS2 is reduced to a single layer. In general, with the change in the WS2 thickness, the direct bandgap at the K point is constant. This is because the corresponding valence and conduction band states at K are only related to the transition metal state and are not affected by the interlayer interactions.

However, when the thickness of WS2 changes from two layers to one, the indirect band gap from Γto K is larger than the direct band gap. This is because the valence band state at Γis related to the d2z orbitals of the metal and the PZ orbitals of the sulfur-based elements. For a single layer of WS2, there is no Coulomb repulsion between the PZ orbitals of the halide elements in the adjacent layers, resulting in a stable valence band state at Γ, which causes an indirect to direct gap transition.

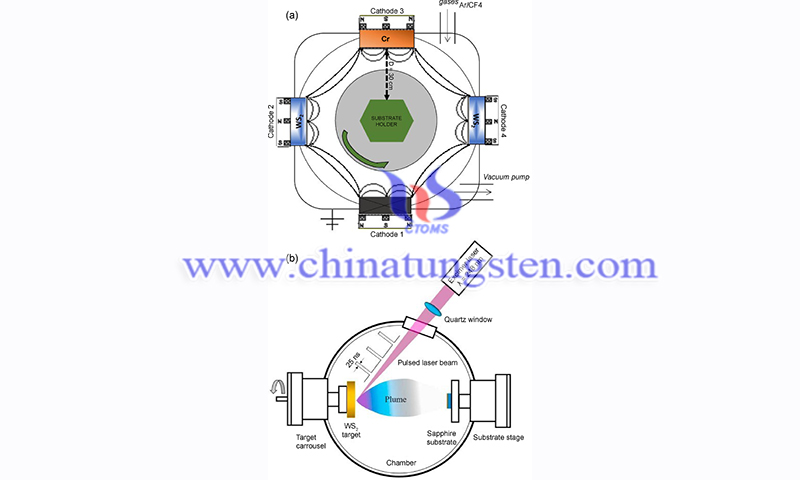

At present, there are a variety of synthesis methods for producing WS2. These methods are categorized into physical, chemical, and stripping methods. Physical methods include pulsed magnetron sputtering and pulsed laser deposition (PLD). Magnetron sputtering growth methods involve the use of charged particles to bombard the target surface under vacuum conditions, causing the target to sputter. In this method, neutral target atoms or molecules are deposited on the substrate to form a thin film. Typically, an inert gas is glow discharged in a low-pressure environment to produce the incident ions.

For WS2 deposition, cathode targets made of tungsten disulfide are sputtered at high negative cathode voltages of 1-3 kV DC or at an RF voltage of 13.56 MHz. In addition, 0.1-10 Pa argon gas is passed into the vacuum chamber to generate a glow discharge. Under the action of the electric field, argon ions are accelerated towards the WS2 target and bombard the target surface with high energy to remove the small target particles deposited on the substrate and form the WS2 film.

To improve the adhesion of WS2 coatings, Rodrigues et al. deposited a Cr interlayer with a thickness of about 400 nm on a Si substrate, followed by a WS2-CF coating. The important advantages of this method are the simplicity of the equipment, the low operating temperature of the substrate, the large coating area, and the ability to produce dense and well-adhered films. In contrast to magnetron sputtering, the equipment used for PLD is complex and its operating principle is relatively complicated. When a high-energy pulsed laser strikes a solid WS2 target, a laser pulse with a sufficiently high energy flux and short pulse width is generated and the target is exposed to this pulse.

The incident laser energy is absorbed by the target, resulting in a rapid increase in temperature, causing some of the target to evaporate and forming a localized high-temperature and high-density plasma. According to the law of gas dynamics, the emitted plasma plume preferentially moves toward the substrate, resulting in the formation of WS2 thin films. In 2018, Tian et al. used PLD technology to grow controllable WS2 thin film layers on sapphire substrates.

They found that the thickness of 2D WS2 films can be precisely controlled by controlling the number of incident pulses (single and multilayer films were successfully prepared). The most significant advantage of this method of using a deposition chamber for growing WS2 films using PLD is that the thickness of the films can be controlled. The films are uniform and of good quality, but it has the disadvantage of high cost and complexity of the operation.

Cited Article: Ding J, Feng A, Li X, et al. Properties, preparation, and application of tungsten disulfide: A review[J]. Journal of Physics D: Applied Physics, 2021, 54(17): 173002.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com