K Doped Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 06 August 2020 13:50

It has been a very popular situation for our company that our customers are inquiring a product, whose chemicals are unknown for both sides. The only one our customers know is the material related to tungsten. However, as for the large category of tungsten, it is difficult to provide a suitable material with such information, so that we have to find out a solution for that.

This time, we also encounter the same issue. We get a sample from our clients, and arrange the testing. As for tungsten is a refractory metal, which has been difficult to be used chemical method, we only test in by metal element analyzer. The testing result is that the material is with over 99.85% tungsten. Therefore, we recommend it as pure tungsten or K doped tungsten.

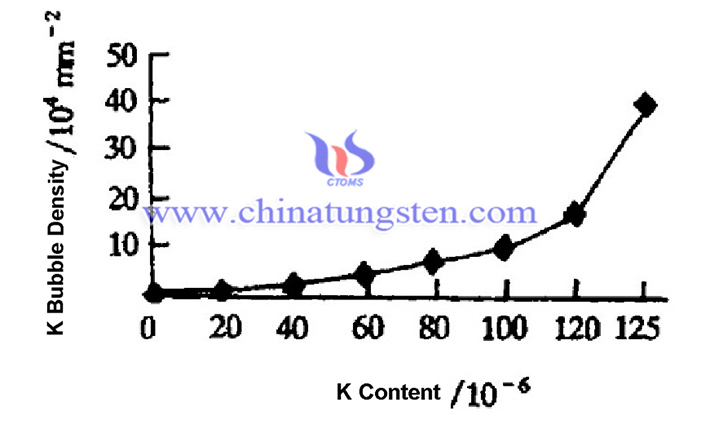

Most of the customers are familiar with K doped tungsten wire but not electrode, actually K doped tungsten electrode is with the same chemical as the wire and the same properties, which is to decrease the deformation at high temperature. K is doped in the process of reduction from tungsten oxide to tungsten powder, which can assure the mixing result of the powder. During forging, as for the crystal of K is larger than tungsten, they are kept in the rod and forged together with tungsten. With content of 30~90ppm K, higher content, denser the K bubble, and better anti-deformation property. Following is an image showing the relationship between K content and K bubble clearly.

There is a factor we need to point out that, during the production, the content of K is not as higher as better, as for K is also can be recommended as impurities, the forging process is influenced if the K is very high, such as higher than 120ppm, then the quality is influenced, for the bubble is existed in the rod and will be horizontal growing. Therefore, the ideal content of K doped is controlled in 30~90ppm for both wire and rod.

- Tungsten Metals Manufacturer & Supplier, Chinatungsten Online: www.tungsten.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com