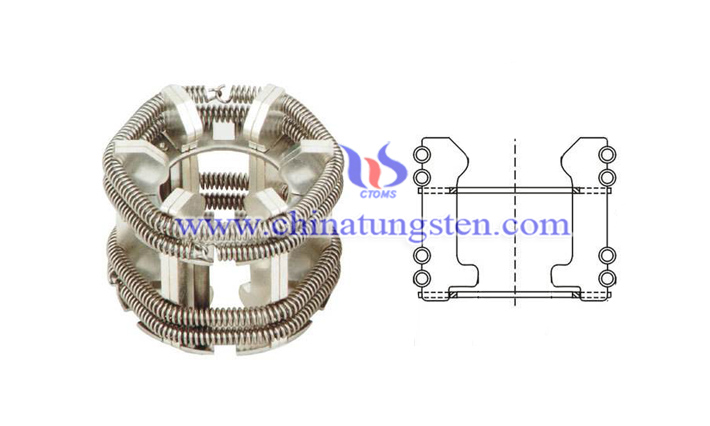

Copper Bonded Tungsten Copper High Voltage Contact

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2020 15:55

With the development of high speed railway both in China and whole world wide, the application of high voltage related equipment has been increasing largely. High voltage contact is one of them.

As for the contact of the electricity will result in high temperature and electricity conductivity, the choice of material have been very important.

1.0 Hardness. Suitable hardness makes the larger contact, lower resistance, and also can lower down the contact temperature, decrease contact bonding, increase the wear resistance and longer the lifetime.

2.0 Electricity property. High electricity conductivity is a significant factor to connect the electricity system for the whole equipment operation. However, as for the contact momentary will direct into high temperature, therefore, the material requires high electricity conductivity and high temperature resistance, which assures the working and the contact will not be melted.

3.0 Thermal conductivity. The connection of electric contact will release high heat, which requires the material with high thermal conductivity, so that the heat can be conducted, but not gathered in the contact area and increase the high temperature of the point.

4.0 Chemical property. The contact should be with stable chemical properties, gas corrosion resistance and high volatility.

Considering the above factors, copper tungsten is chosen for it has owned all the above advantages, however, as for its thermal conductivity is still not enough for high voltage industry, it is welded on the copper part. Furthermore, in order to improve the electricity conductivity, the surface is always coated with a layer of silver.

This silver coated copper bonded tungsten copper contact is the best material for high voltage industry. The bonded part is applied both the moving and static contacts. Among them, the tungsten copper part can also be made with different contents, and 70W30Cu and 80W20Cu are used most widely. Surely, if your design is with customized drawings and materials, please do not hesitate to contact Chinatungsten by sales@chinatungsten.com.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com