Copper Bonded Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2020 16:40

Tungsten electrodes have been so popular for TIG welding and GTAW welding, including cerium doped, lanthanum doped, yttrium doped, thorium doped, zirconium doped, etc.

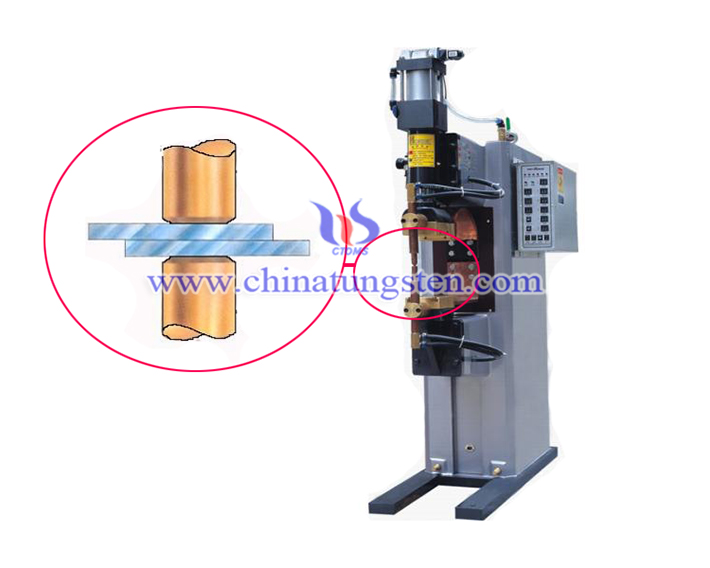

But besides them, there are many other welding types and electrodes. These days, we encountered the inquiry of spot welding electrodes, which is required with type of copper bonded tungsten electrode. Actually this is a new type, whose history is much shorter than the TIG welding electrodes.

The requirements of copper bonded type are much more accurate than rare earth doped.

1.0 The tungsten part is as pure as 99.95% min.

2.0 The bonding of tungsten and copper is using special welding, so that the welding layer is without resistance and crack.

3.0 The whole processes of sizes and bonding are applied cold processing by grounding machine, wire cutting, so that the properties are remained.

4.0 Higher requirements on the sizes and tolerances.

Nowadays, the copper bonded type tungsten electrode is widely used in electronic in car industry, such as Bosch, Denso, Continental, etc. By using spot welding, or resistance welding, the parts with thickness over 3mm, or diameters range from 3mm to 12.5mm and be jointed together.

Copper part in the electrode is applied its high electric conductivity, which can convey the heat to electrode in high speed. Tungsten part receives the heat and the materials between the upper and down electrodes are yielded and squeezed together.

This kind of bonded electrodes have been many types, the choose of one part is with high electric conductivity, such as copper, silver, etc. the other part is with low electric conductivity, which is to make sure the welding electrode is not left on the surface of welding objectives during welding, the materials can be tungsten, tungsten copper, molybdenum, etc. And copper bonded type tungsten electrode is the most popular one in spot welding.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com