Tetragonal Nano Tungsten Oxide Preparation by Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Sunday, 10 November 2019 23:49

Nano WO3 has a strong absorption capacity for electromagnetic wave. It can be used as an excellent absorption material in the utilization of solar energy and an important invisible material in the military. It also has a huge specific surface area and remarkable surface effect. It has been widely used in fuel cells, chemical sensors, optoelectronic devices and other fields.

In recent years, due to the development of preparation technology of tungsten oxide nanomaterials, the discovery of metastable and efficient color change and proton transfer properties, based on the ultraviolet absorption and chemical activity of tungsten oxide nanomaterials, the application of materials has expanded to many fields such as information storage, color change window, large area information display screen, automobile reflector, etc. These unique properties of tungsten oxide are closely related to its structure, morphology and particle size. Therefore, the research on the synthesis of nano tungsten oxide with special structure and morphology has become a hot topic.

In order to further develop the preparation of tungsten oxide nanowires, tetragonal tungsten oxide nanopowders were prepared by organic acid assisted hydrothermal synthesis. The technical scheme is as follows:

(1)The crystal powder of sodium tungstate [Na2WO4 · 2H2O] was dissolved in water, and a proper amount of citric acid was dissolved in water as an auxiliary reagent. The two were mixed in the ratio of 0.3:1 to 1.5:1 to get a clear mixed solution;

(2)Adjust the pH value of the solution with hydrochloric acid between 0-2.0, and ultrasonic treatment for 10 minutes;

(3)The precipitation and solution are added to the stainless steel reactor lined with polytetrafluoroethylene, and the constant temperature is 12-24h at 120-200 ℃;

(4)After cooling, filter or centrifugally wash, and finally wash with anhydrous ethanol to get powder; dry the powder at 60 ℃ to get tungsten oxide nano powder.

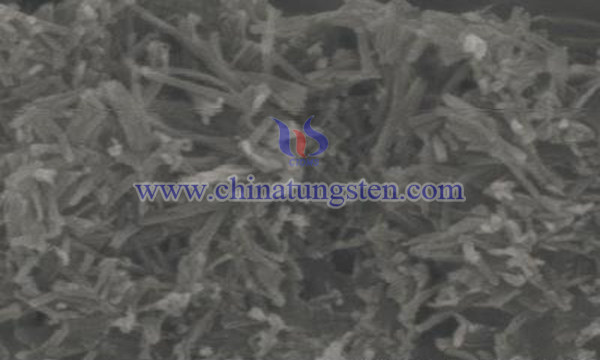

The tetragonal nano tungsten oxide obtained by hydrothermal method has uniform size, average side length of 80-100nm and almost no agglomeration. And the process is simple, common for equipment requirements, suitable for a wide range of promotion.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com