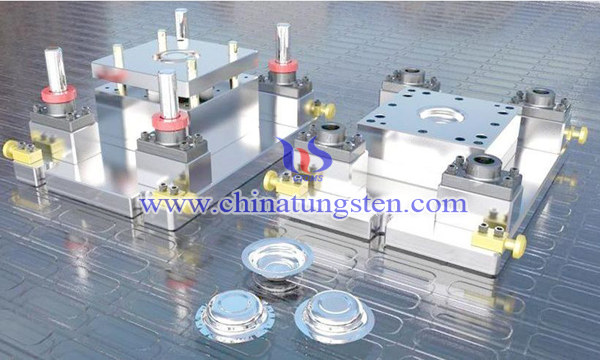

Nano Tungsten Carbide Coating on Die Surface

- Details

- Category: Tungsten Information

- Published on Saturday, 07 September 2019 22:31

With the rapid development of material surface modification technology, thermal spraying, plasma spraying and other technologies are more and more widely used in the die. After the traditional die is used for a long time, the surface of the die will be damaged, cracks and other problems, maintenance troubles, and need to replace the new die.

Therefore, by coating a layer of nano tungsten carbide coating on the surface of the die, the problem of high maintenance cost of the die surface damage can be solved. In order to achieve this goal, the researchers tried a method to fabricate nano tungsten carbide coating on the die surface, including the following steps:

Firstly, 20% tungsten carbide is mixed with 70% Ni-based alloy powder, then 10% tungsten carbide is fully mixed. After stirring, the paste is made by adding binder. Then the paste is coated on the surface of the mould, and then the coated mould is placed in the drying chamber for drying. After drying, the mould is heated in the heating furnace and cool in a greenhouse. The cooling die is placed under the scanning electron microscope for coating detection. If cracks are found on the coating, the defective product will be repainted, and vice versa, the qualified product.

The temperature of the heating furnace is controlled at 200 - 600 ℃ and the time is controlled within one hour. By coating nano tungsten carbide coating on the surface of the die, the repair of the die is simple, the repair cost is low, and the repaired coating has high toughness, is not easy to crack, and the later maintenance is simple.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com