Tungsten-containing Composite Films Preparation by Homogenizing

- Details

- Category: Tungsten Information

- Published on Saturday, 07 September 2019 21:46

Tungsten-containing material is the best high-energy radiation shielding material. It has excellent attenuation and absorption ability to X-ray and radioisotope radiation, which is more than 40% higher than the commonly used lead. It has been widely used in medical diagnosis and treatment, nuclear energy utilization, product safety inspection, industrial flaw detection and other fields.

However, the high hardness, high melting point and brittleness of tungsten limit its application. With the development of technology, the requirement of parts with high specific gravity of tungsten-containing materials is becoming more and more complex, and the processing of tungsten-containing materials is becoming more and more difficult. How to optimize the use of high density tungsten-containing composites and expand the application scope of tungsten-containing composites is the focus of research on tungsten-containing composites.

Homogenizing method is a common method for preparing thin films. Homogenizing method relies on centrifugal force and evaporation to thin the deposited films. In the field of high-end precision science and technology, it is feasible to directly replace tungsten alloy radiation shield components with tungsten composite films prepared by leveling method. The manufacturing process of this kind of film composite requires the following steps:

A. Preparation of sol:

a. Preparation of W-Ni-Fe mixed powders with a ratio of 90:7:3;

b. Preparing organic additives, the components of organic additives are terpineol 70-80%, ethyl acetate 3-6%, ethyl cellulose 9-12%, glycerol 3-10%, hydrogenated castor oil 2-4%.

c. To prepare the sol according to the prescribed formulation, that is, the quality percentage of tungsten-containing metal mixed powders and organic additives is (65-75): (35-25);

d. Select the above metal powders with appropriate particle size, dry them in proportion and grind them by ball mill, and then prepare slurry. The preparation method is to add ethyl acetate, metal powder, ethyl cellulose, glycerol and hydrogenated castor oil to terpineol in turn according to the weight ratio of each component. Or high-speed mixer will mix the slurry evenly; then the slurry vacuum defoaming treatment, through the appropriate mesh sieve, remove the large particles, and finally get the sol.

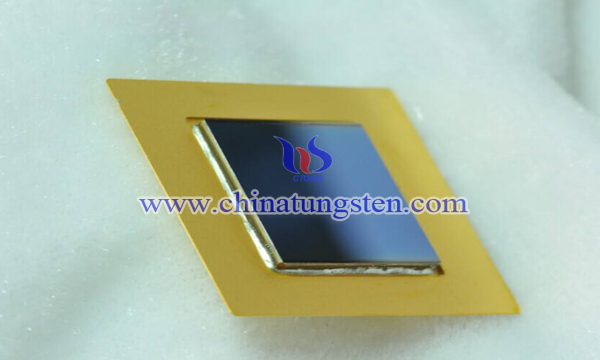

B. Preparation of thin films:

a. The slurry sol prepared above is used as a film-making machine.

b. Prepare the matrix in advance and clean the matrix. The matrix is a CT mask component.

c. The above-mentioned slurry sol droplets were adsorbed on the substrate of the pallet, and the pre-rotating speed was controlled to 600 r/min and the time was controlled to 15 s. The high-speed rotating speed was 2000 r/min and the time was controlled to 40 s. Finally, the tungsten-containing film composite material was obtained.

The preparation process of tungsten-containing composite films by leveling method is simple. The prepared films have certain shielding properties, can effectively block X-ray, and increase the matching degree between the films and other parts. With controllable film thickness and high uniformity, a series of problems caused by difficult processing of tungsten and tungsten alloys are effectively solved.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com