Direct Growth of Tungsten Trioxide Thin Films on Tungsten Sheets

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 August 2019 21:40

Tungsten trioxide, as a catalytic material for hydrogen production from water decomposition, has the advantages of photoelectric double response effect, stability, low light-on voltage, high hydrogen production efficiency, and is also a good electrochromic material.

To use tungsten trioxide as photocatalyst to decompose water to produce hydrogen with low cost and high efficiency, it is necessary to reduce the cost of preparation of catalytic materials, which can be prepared in large area and have good uniformity. More importantly, the preparation process has high repeatability and can be industrialized.

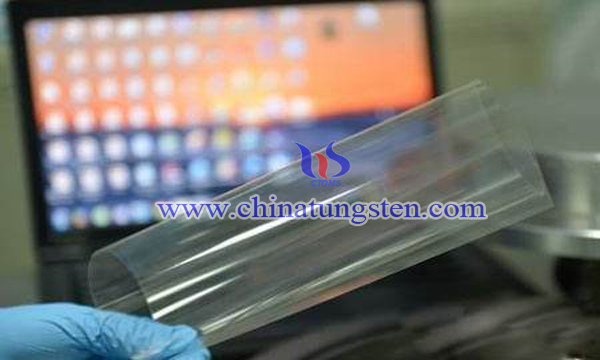

Some scholars use direct growth method to grow tungsten trioxide thin films on tungsten metal sheets in oxygen atmosphere. This method is easy to operate, requires simple equipment, greatly reduces the cost, and has a high film forming rate. Its specific operation is as follows:

The first step is to place the tungsten sheets in the constant temperature zone of the vacuum tube furnace.

In the second step, when the temperature in the tube is increased to 140-160 ℃ at the rate of 8-12 ℃/min, oxygen is introduced. After ventilation, the pressure in the tube rises slowly. When the temperature in the tube rises to 790-810 ℃, the pressure in the tube reaches 0.7-1.3 atm. Then the temperature is kept at 790-810 ℃ for 13-17 min, and then the temperature is naturally cooled to room temperature.

The advantages of the above method are that it can prepare large area tungsten trioxide thin films by direct oxidation and the uniformity of tungsten trioxide thin films is good. More importantly, the preparation process has high repeatability and is convenient for industrial production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com