Spherical Tungsten Carbide Powder Property and Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 June 2019 17:51

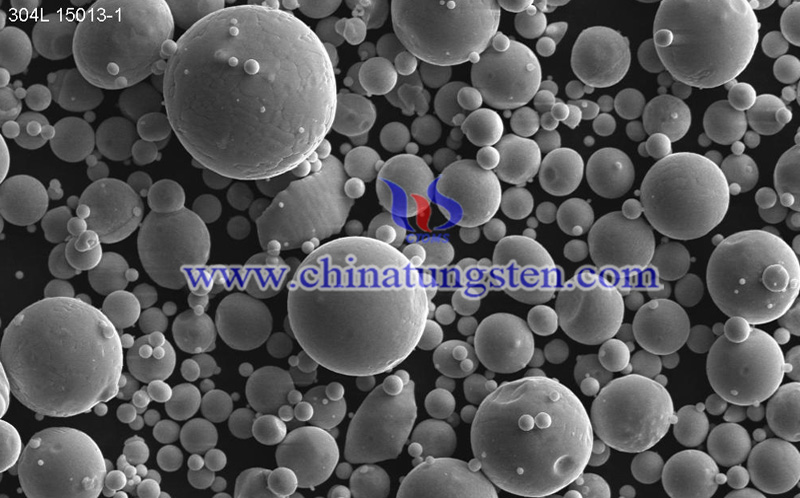

Spherical tungsten carbide powder has the microstructure of fine equiaxed dendrites, its morphology of dense homogeneous spherical WC particles. It maintains a stable chemical property, good fluxibility and hardness, and outstanding wear or abrasion resistance.

The particle sizes of cast spherical WC powder range from 0.025 mm to 0.25 mm which exhibits dark gray luster. Its specific density is 15.8~16.7 g/cm3 with micro-hardness ranging from 2700~3300 kg/mm2. They show a fine non-acicular structure with a higher hardness than conventional FTC (> 3,000 HV0.1). The increased apparent density combined with a better flowability enables an increase of hard particles in wear resistant coatings and components produced by infiltration.

The spherical tungsten carbide powder is generally made from regular cast tungsten carbide power or the mixture of tungsten (W), tungsten carbide (WC) and carbon (C). Microstructure of cast spherical tungsten carbide powder. The melt is cast through quenching into extremely hard solid particles of fine crystal structure. The property of Spherical Tungsten Carbide Powder are High temperature hardness, Toughness and Compressive strength:

High temperature hardness

With increased grain fineness, spherical tungsten carbide powder feature improved hardness properties at high temperatures, so that strength benefits emerge in high temperature use particularly for wear protection layers made from them. The nano-scale WC raises the strength level a stage higher.

Toughness

A smaller grain size in the spherical tungsten carbide powder phase with the same Co content results in a decrease in the difference between WC grains and hence to a reduction in particle movement.

Compressive strength

The high compressive strength of spherical tungsten carbide powder is one of the most important properties in these materials, as it is significant in practically all technical applications. After diamond, hard metal (cemented tungsten carbide) is the most pressure resistant material. This property is also of predominant significance in wear protection. The increase in the microstructure leads to a significant rise and as a result it has the highest compressive strength.

Applications of spherical tungsten carbide powder. It is particularly applied to thermal surfacing techniques, such as powder welding, flame spraying, plasma spraying, HVOF (high velocity oxy-fuel). As the high melting point and high hardness of tungsten, it is been set as an important strategic material, widely used in tungsten carbide tools, electric filaments, tool steel additives, rockets, space vehicles, nuclear reactors and other fields. Using powder metallurgical processes, it is possible to produce parts of nearly any shape, which can contain hard materials or diamonds together with a metal binder, reinforcing the hardness of diamond tools. Excellent for deep well drilling tools and rods, crusher jaws, mixers, concrete & stone saws, hot-pressed tools, screens & conveyors, extrusion housings and hard additives to diamond bits and saws.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com