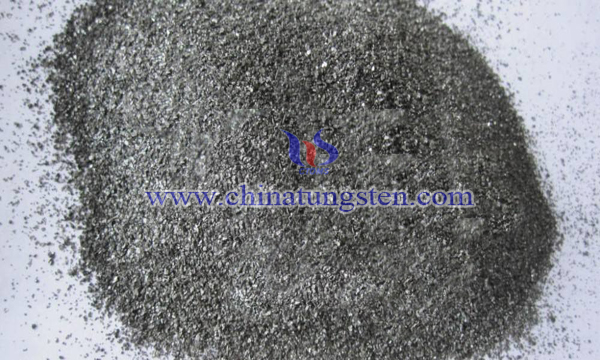

Narrow Grain Ultra Coarse Tungsten Carbide Powder Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 October 2018 23:10

As the main raw material of high performance cemented carbide for mining and engineering, the particle size distribution of ultra-coarse tungsten carbide powder has a decisive influence on the quality of cemented carbide. The granularity distribution of tungsten carbide powder is too wide, which will significantly reduce the properties of ultra coarse cemented carbide prepared by using tungsten carbide powder.

The WC powders sintered by traditional sintering process have obvious aggregation and often appear pseudo-coarsening phenomenon. It is easy to become the crack source of fatigue failure in heavy cemented carbides. Therefore, it is important to prepare ultra-coarse grain WC powders with narrow particle size distribution.

In view of the particle size distribution of tungsten carbide powder, a method for preparing narrow particle size ultra-coarse tungsten carbide powder has been published on the academic website. Methods include these steps:

1.Coarse W powder was obtained by reducing the narrow Fsss particle size to 15 micron WO3 powder at 1300 ℃ for 3 h. In the stirred ball mill of stainless steel, 50kg of high-purity coarse tungsten powder with a ball-to-material ratio of 2:1 and 4 hours after ball milling, the coarse tungsten powder with a particle size of 26 micron can be obtained by vibrating screen between 200 meshes and 270 meshes.

2.The carbon content of the coarse tungsten powder was 6.17wt% and 2H was mixed by ball milling. Then the graphite boat was loaded and carbonized in a vacuum frequency induction carbonization furnace. The carbonization parameters were kept at 1700 ℃ for 4 h, then heated to 2400 ℃ for 3 h, and then cooled to discharge temperature.

3.The obtained tungsten carbide agglomerates were crushed by rolling mill for 3 hours at a ratio of 1:1. The obtained powders were sifted through 100 meshes, and the grinding balls were removed. The WC powders with super-coarse particle size of 30 micron, narrow particle size distribution of 39.8 micron and 80 wt% tungsten carbide between 20 micron and 80 micron were obtained. The chemical purity of tungsten carbide powder is higher than or equal to 99.9wt%; X-ray diffraction phase analysis shows that the tungsten carbide powder does not contain W2C and other impurities, the content of combined carbon is 6.10wt%, the content of total carbon is 6.16wt%, the content of free carbon is 0.06wt%, Fe is 0.01wt%, Mo is 0.005wt%, and the chlorinated residue is less than 0.01wt%.

The WC-C cemented carbide with narrow particle size and ultra-coarse tungsten carbide prepared by this process has high toughness and good thermal fatigue resistance. The average grain size of the WC cemented carbide is more than 6 micron. The alloy is especially suitable for new cemented carbide tools with excellent comprehensive performance and long service life, such as mining tools, oil drilling and mining tools, shearer pick tools, shield machine tools for tunnel engineering.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com