High Quality Submicron Tungsten Powder Preparation Method

- Details

- Category: Tungsten Information

- Published on Sunday, 22 April 2018 15:51

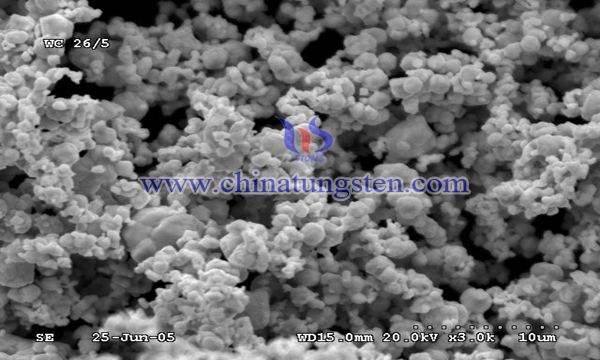

Tungsten powder is the main raw material for the preparation of hard alloys and many industrial products. According to its size, tungsten powder can be classified into coarse grains, fine grains, submicron, nanometer, etc.

A major application of submicron tungsten powder is electron tube cathode material. For example, microwave vacuum electronics, the stable preparation of the raw material of submicrometer tungsten powder determines the quality of the device performance, so the preparation method of submicron and narrow particle size tungsten powder is very important.

Specific steps for the preparation of sub-micron narrow particle size distribution tungsten powder include:

(1)Solution preparation: Use APT-0 as raw material. Static pyrolysis at 270~350°C in muffle furnace or dynamic pyrolysis in rotary furnace for 1~3h, obtaining the dissociation material based on amorphous ammonium metatungstate (AMT). Weight loss rate is controlled at 7~8%, mix with 7mol/L ammonia solution or deionized water for 2~4h. After 30 minutes, it was filtered to obtain ammonium tungstate solution.

(2)Dispersion: Add dispersant solution and dispersion enhancer simultaneously in ammonium tungstate solution and stir for 10-30 minutes, the dispersant is an aqueous solution of a low molecular weight polyacrylic acid (PAANH4) aqueous solution, dispersant solution is an aqueous solution with a dispersant content of 5 to 10% by weight. The amount of the dispersion strengthening agent for methanol and dispersant solution was 1 to 10% by volume of the ammonium tungstate solution, and the amount of the dispersion strengthening agent was 5.0% by volume of the ammonium tungstate solution.

(3)Spray drying: A rapid crystallization and drying of dispersed ammonium tungstate solution by spray dryer equipment, fine-grained hollow thin-walled spherical ammonium tungstate crystals was obtained. Spray drying is a kind of equipment for high-speed centrifugal spray. The spray tower is internally lined with titanium or lined with teflon, inlet wind temperature is 250~350°C, outlet wind temperature is 80~150°C, centrifugal disk speed is 10000~25000 rpm/min.

Pyrolysis: Ammonium tungstate crystals pyrolysis with air or nitrogen in a muffle furnace or in a rotary furnace for 1–3h in static state and dynamic state under 500~600℃, yellow tungsten oxide precursor was obtained. Under a nitrogen-hydrogen gas or hydrogen atmosphere in a muffle furnace static or rotary furnace dynamic pyrolysis at 600 ~ 700 °C and make a mild reduction for1 ~ 3h, after that, blue or purple tungsten oxide precursor was obtained.

Hydrogen reduction: Double boat loading, loading capacity 500~1000g/boat. The material feed is in the direction of hydrogen and the hydrogen flow rate is 40~45m3/h. The hydrogen dew point is lower than -60°C, and the boat speed is 8 to 12 minutes/boat. After hydrogen reduction at 600~900°C for five segments, submicron and narrow size tungsten powders are obtained.

The sub-micron narrow particle size distribution tungsten powder produced by the above process is a powerful guarantee for high-quality products and it can be used to produce high-performance tungsten carbide, tungsten electron cathode substrates, high-uniformity fine-grain tungsten targets and other tungsten products.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com