High Purity Tungsten Powder Production Process Decomposition

- Details

- Category: Tungsten Information

- Published on Sunday, 22 April 2018 15:39

How to avoid the increase of impurities and further purify impurities during the reduction of tungsten powder is a very important task.

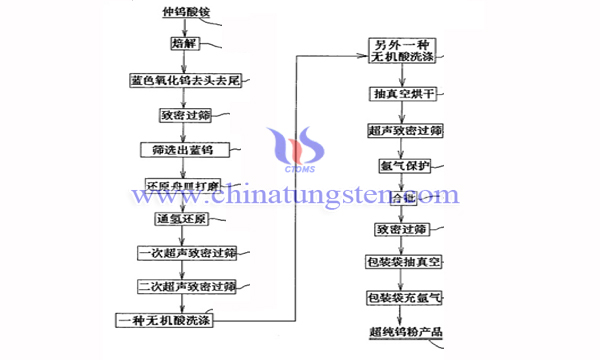

High purity tungsten powder production process is:

1)Baking decomposition

The raw material of ammonium paratungstate (APT) is added into the rotary furnance, and the ammonia gas generated by decomposition of ammonium paratungstate (APT) is used to maintain the reducing atmosphere in the furnace at a temperature of 550-750°C. Ammonium paratungstate (APT) decomposes at high temperatures to form tungsten trioxide. The tungsten trioxide is then reduced by the ammonia gas to slightly reduce the hydrogen to blue tungsten oxide.

After the blue tungsten oxide was sieved through a 120 mesh stainless steel vibrating screen, the blue tungsten oxide dropped after the wall of the sticky furnace tube with a high impurity content was removed.

2)Reduction

The screened blue tungsten oxide is placed in a stainless steel boat and passed through a reducing furnace at a temperature of 800-950° C. and then reduced to average particle size of 3.0-6.0μm metal tungsten powder that is under hydrogen atmosphere with a dew point that less than -60°C and an oxygen content less than 5 ppm.

The reduced tungsten powder was twice passed through a 200 mesh stainless steel screen to remove impurities using an ultrasonically sealed shaker. The sifted metal tungsten powder is barreled and protected by an inert gas.

3)Pickling

Wash tungsten powder with 1%-5% inorganic acid for 20-40 minutes, then wash tungsten powder with another 1%-5% inorganic acid for 20-40 minutes. Use pure water to clean the surface of the tungsten powder to neutrality, PH = 5-7. Dry tungsten powder in a vacuum atmosphere at a temperature of 85‐95°C. Use an ultrasonically sealed shaker, the acid washed tungsten powder was passed through a 200 mesh stainless steel screen. Pack the sifted metal tungsten powder into a barrel and pass inert gas protection.

The acid-washed sifted tungsten powder is placed in a mixing machine, filled into a packaging bag, and then the packaging bag is evacuated, filled with inert gas and sealed, so that the ultra-pure tungsten powder is isolated from the air during the preservation process to prevent oxidation.

Through the above process, high-purity tungsten powder with a purity of ≥99.99% can be obtained, with an average particle size of 3.0-6.0 μm, an oxygen content ≤300 ppm.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com