Cs0.32WO3 Applied for Coating Glass

- Details

- Category: Smart Glass

- Published on Wednesday, 12 February 2020 11:44

- Written by Yahong

- Hits: 1528

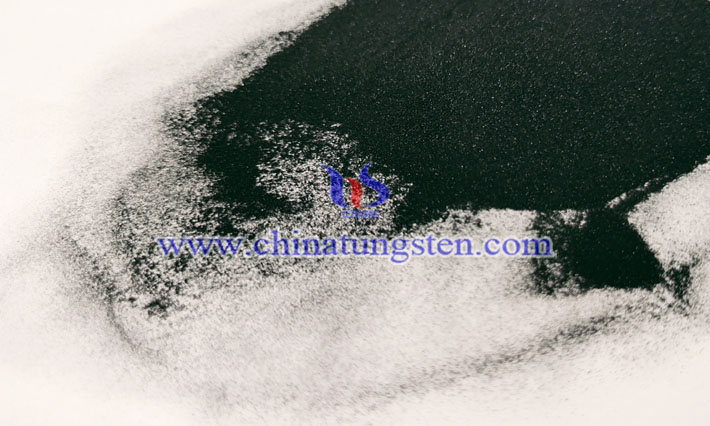

Cs0.32WO3 for preparing coating glass is known as cesium tungsten bronze with heat shielding property. According to the experts, Cs0.32WO3 nano powder also has NIR photothermal conversion property. Some experts have obtained the Cs0.32WO3 powder of mean hydrodynamic diameters of 1,310, 250, 180, and 50 nm before grinding and after grinding for 1, 2, and 3 h, respectively. Their NIR photothermal conversion property in the aqueous dispersions was examined at a fixed particle concentration of 0.008 wt.%. For the samples before grinding and after grinding for 1 and 2 h, 5 wt.% of PEG 6000 was added to avoid the occurrence of precipitation.

More details, please visit:

http://cesium-tungsten-bronze.com/index.html

The blank solution with 5 wt.% of PEG 6000 in deionized water was also investigated for comparison. It was obvious that, for the blank solution, the NIR irradiation caused a temperature increase of only about 3°C after 10 min. For the aqueous dispersion of Cs0.32WO3 powder before grinding, the NIR irradiation-induced temperature increase was also slightly higher than the blank solution. However, for the aqueous dispersions of Cs0.32WO3 powder after grinding, the temperature was significantly raised under NIR irradiation. Also, with increasing grinding time, the temperature increase became more significant. For the aqueous dispersion of Cs0.32WO3 nanoparticles obtained after grinding for 3 h, the temperature increase after 10 min was 15°C. This revealed that the NIR photothermal conversion capability of Cs0.32WO3 nanoparticles could be enhanced by the decrease of particle size.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com