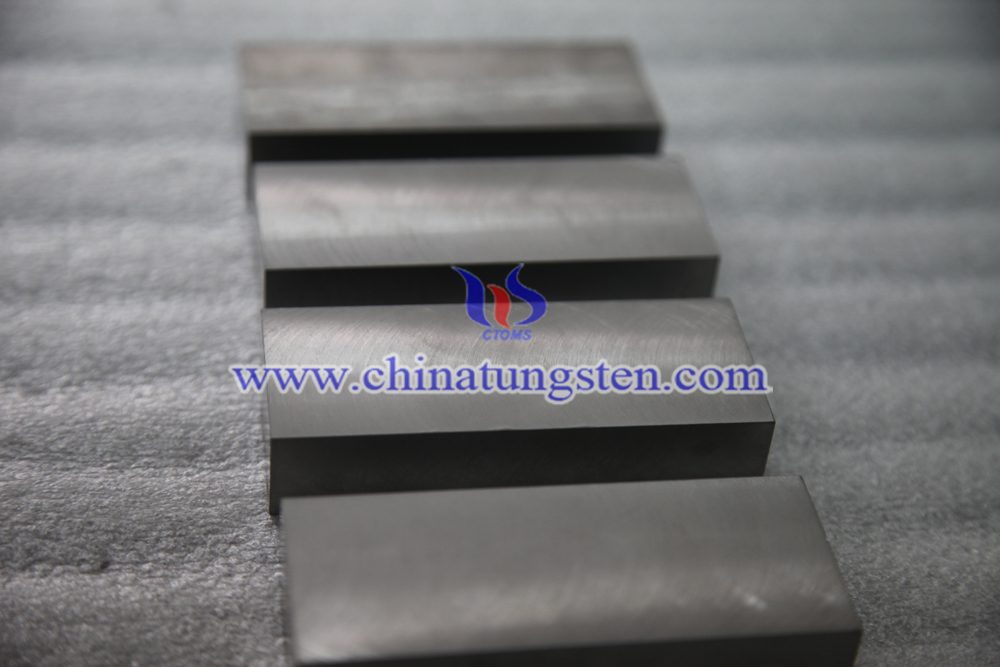

Tungsten Alloy Electric Upsetting Block

- Details

- Category: Tungsten Information

- Published on Friday, 11 August 2017 15:58

The upsetting process is widely used in the production of engine valve materials. As the upsetting block for upsetting, it will bear the sustained effects of high temperature and high pressure.

Upsetting die blocks materials used for fabricating engine valve should possess excellent red hardness, certain toughness and good processing ability. In order to produce upsetting die blocks of high performance, adding high melting point metal in the alloy can meet the requirements. Tungsten has the highest melting point, good thermal conductivity and higher strength and hardness, which is an ideal material for hot working die.

Because the upsetting process is an intermittent periodic operation, the upsetting block material will bear the repeated effect of thermal fatigue stress. When the speed of cars or other transport are getting higher, the engine gas temperature will be higher, which makes the valve material work under worse conditions. It requires the valve material to have higher resistance of temperature and wear.

Tungsten alloy has good conductivity and thermal conductivity. Because of the content of tungsten is 80%, it has better high temperature performance. Tungsten heavy alloy meets the requirements of upsetting block material. It has high strength and high temperature hardness, high anti-deformation ability, and certain thermal conductivity and conductivity. Data in practice shows that in valve production process, replacing original upsetting block with tungsten alloy upsetting block, after being used more than two years, the cost of electric upsetting can save 80% compared with the previous year, from which we can see that its economic benefit is great.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |