The Pressing of Non Step Cylinder Partsa

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 July 2017 16:56

For hard alloy products, the mixture is hard, pressing pressure is large, which brings difficulties for forming complex parts and possibility of plastic processing, so complex parts are usually forming first then change shape on the lock block. The simplest pressing parts are the ones without steps.

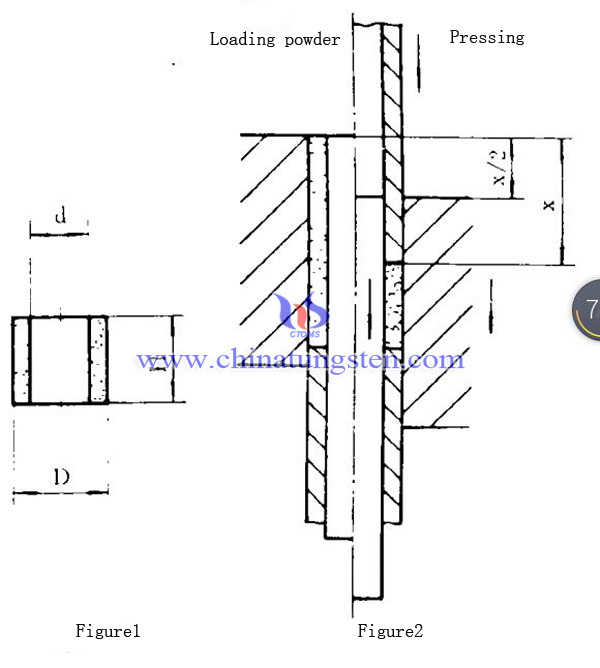

In the forming process of powder metallurgy parts, the pressing of non step cylinder parts (hereinafter referred to as bushings) is probably the most basic and simplest. When the wall thickness ratio is not large (for example, H/T< 3), it can be satisfactorily shaped by single action pressing, as shown in Figure 1.

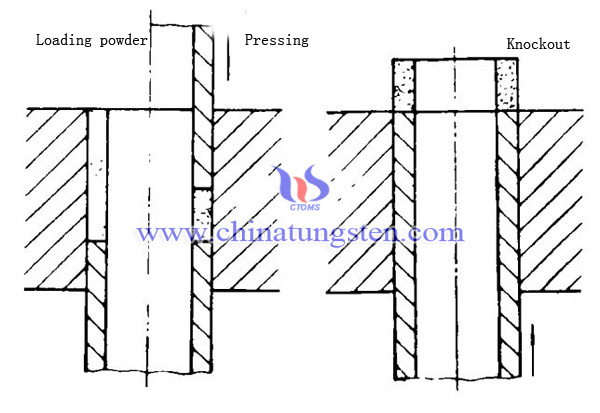

However, when the wall thickness of the shaft is relatively large (such as H/T>3), in order to improve the uniformity of the density of the blank, it is necessary to consider the use of double action pressing, double friction suppression. For example, the shaft sleeve shown in figure a can be molded using a die in which both the female die and the mandrel are free floating. Figure b illustrates the forming principle of the floating die. The bottom part is hold-on when forming, and the uprush stamping the down stroke is x. Since the female die and the mandrel are moved downward by x/2, so to cavity die, uprush and bottom part push x/2 to block black. The maximum density difference between the two ends of the blank occurs, which greatly reduces the unevenness of the density of the blank.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com