Wolframite Slime Recycle

- Details

- Category: Tungsten Information

- Published on Tuesday, 27 June 2017 17:32

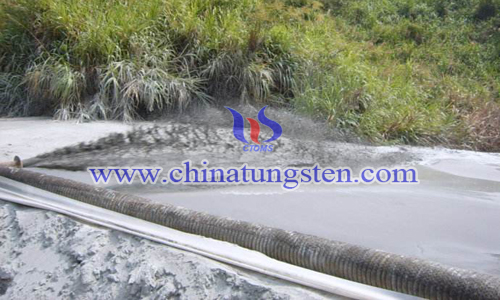

Tungsten concentrate is fragile mineral, during beneficiation process, wolframite slime can easily come into being, and will be neglected in tabling. There are still much tungsten element in slime.

According to statistics data, tungsten metal in wolframite slime accounts for 11~14% in original mine, even higher than it. To improve recovery rate of slime is important to achieve efficiency.

Usually wolframite is dealt alone, wolframite slime recycle accounts for 3~8% of total recycle rate. It is effective measure to save cost and optimize resource. Processing method for wolframite slime is diverse, gravity separation and flotation method are the most widely used.

Gravity separation is physical method for wolframite slime recycle. In early period, we mainly use whole tabling gravity separation method. It is simple, but can only sieve wolframite slime bigger than 30um. Recycle rate is lower than 35%. Later the process is upgraded, it is beneficiation process of classification, desulfurization, tabling, centrifuge saparation. The process is making primary category before gravity separation, magnetic machine and centrifuge machine are used subsequently, gravity separation is targeted and thus promote 30% recycle rate.

Apart from that, according to fine character of wolframite slime, flotation method is efficient way. Almost every method for float tungsten scheelite can be used to recycle slime. Tungsten concentrate has its character, it has weak magnetic property. So we can use magnetic separation machine or centrifuge machine to concentrate. It can achieve recycle rate of 80~90%.

In fact, flotation and gravity separation both have advantages. So in reality, most mines adopt combined method of flotation and gravity separation. No matter which method is taken, primary grade is a key process.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com