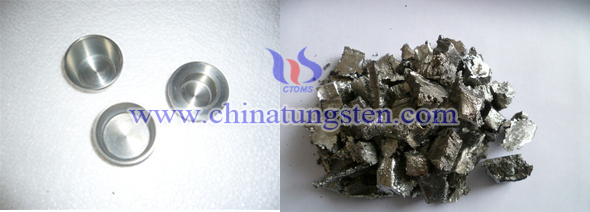

Tungsten Crucible for Rare Earth Smelting

- Details

- Category: Tungsten Information

- Published on Monday, 25 April 2016 16:52

Tungsten Crucible is one of the important deep-processing tungsten products which is now widely used in smelting of rare earth for its excellent corrosion resistance and good anti-wear properties as well as a high temperature strength. The choice of tungsten crucible has an important influence on rare earth metal smelting. Thus, in the preparation of tungsten crucible for rare earth smelting, users should pay more attention to the followings.

The first is for the selection of tungsten powder. Tungsten powder is the main raw material for tungsten crucible, the grain size of tungsten powder plays a crucial role on the quality of the finished tungsten crucible. Inappropriate choice of the grain size of tungsten powder will make tungsten crucible have crack during the pressing. Therefore, the grain size of tungsten powder cannot too coarse. If too coarse, the space in the pressing process will be great which will reduce the density of pressed compact and easily lead to cracking. If the users choose too small grain size, movement of position and the amount of deformation between the tungsten powders will increase at the time of pressing. Due to the flabby of elastic stress, the finished tungsten crucible would have crack finally. Accordingly, the grain size of tungsten powder of tungsten crucible for rare earth would better between 2.5μm and 3.0μm. In addition, the oxygen content of the tungsten powder should be less than 0.1%.

Next is the control of pressure in processing. While pressing tungsten crucible with a strong pressure, tungsten powder will have a serious distortion. On the other hand, the strong pressure would increase the elastic stress, and finally, resulting in tungsten crucible cracking. If the pressure is too weak, tungsten crucible cannot enough reach, and it easy to have crack. In addition, the speed of pressure pool should be slow, if too fast, release of elastic stress of tungsten powder will accelerate which would lead to cracking of the tungsten crucible.

Finally is the notice of sintering process. When sintering pressure compact in the medium frequency induction furnace, the sintering temperature should be controlled between 2200 ℃ and 2250 ℃. And the holding time of 3-5 hours is the best. What’s more, the rising rate of sintering temperature cannot too fast or it would cause deformation of tungsten crucible, it is better to rise 80 ℃ or 100 ℃ for one hour.

Tungsten crucible formed by the above ways for rare earth smelting would have better properties and the best effect which can also greatly reduce industry costs.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com