Tungsten Trioxide Denitration Catalyst Selection of High Ash Working Condition

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 18:31

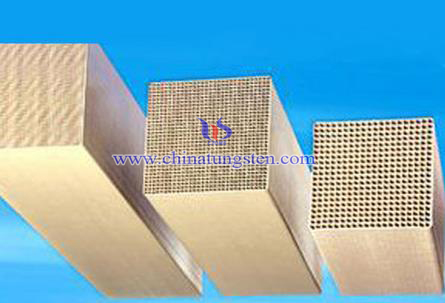

Honeycomb denitration catalyst has a large surface area due to a large number of holes, small intercept, thin wall, thus to require smaller amount of engineering tungsten trioxide denitration catalyst. However, because of its smaller aperture, the property of flue gas passing through is poor, fly ash blocking the bridge is easily occurred at high fly ash conditions; when part of the aperture blocked, the amount of fly ash will have a sharp increasing in the other aperture, and then the whole catalyst occur serious blockage. We know that the catalyst blockage is a serious irreversible running accident, which has to exit the reactor catalyst to clean up when the situation is serious.

Since the thickness of the thin-walled catalyst is average 25% or more smaller than the standard, the pore size is about 5% larger than the standard when at the same number holes, thus to have a better smoke and ash passing through, higher specific surface area , lower engineering required. However, since the thin wall thickness, the wear-resistant is reduced, and partial rupture may be occurred, or even blocked, finally bring a high operating costs.

The majority of our thermal power combustion conditions are poor which demand very large catalyst regeneration. The selection of catalyst sufficient to consider is not only the life of the chemical mechanical strength, but also the mechanical strength required for catalyst regeneration. Under conditions of high fly ash, ignoring design principle, blindly select long and short type catalyst is not desirable. In general, the smaller thickness, the higher the risk of mechanical damage is; besides, these risks will not ease with the hardening end. According to the experience when the fly ash concentration exceeds 30g/Nm3, the catalyst should be used in standard-type catalyst with wall thickness greater than 1.0mm in order to fully meet the requirements of chemical and mechanical life, and the risks of plug fouled and worn does not occurred.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |